Tatted fabric and tatting method

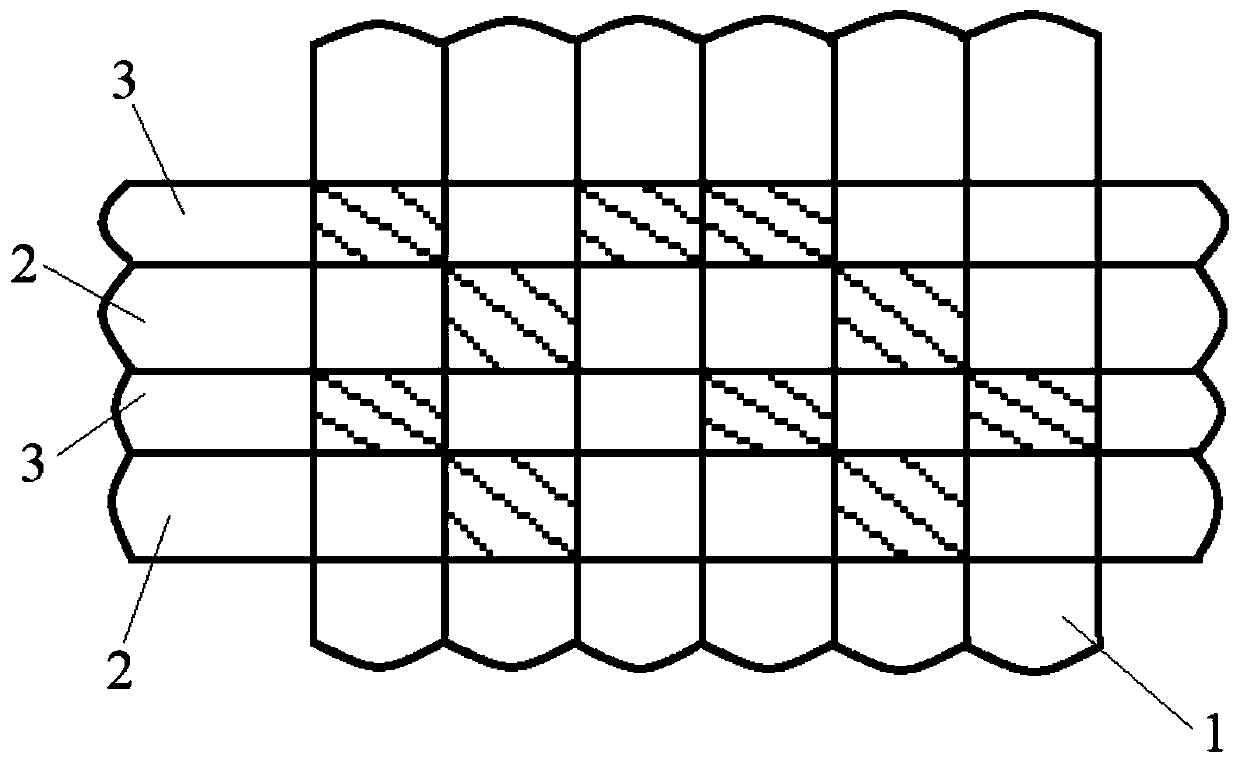

A fabric and weaving technology, applied in the field of woven fabrics and weaving, can solve the problems that the fabric is not elastic, cannot be used as a medical clothing material, lacks comfort, aesthetics and occupational defense, and achieves skin-friendly comfort and stretching comfort, strengthening occupational defense, and improving the effect of aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, the weaving density of the warp yarns is 110 threads / inch, and the No. 1 yarn is formed by plying 2 polyester fibers with a thickness of 40 British counts and cotton fiber blended yarns, and the blending ratio is 35wt% cotton and 65wt% polyester fiber; the weaving pitch of antistatic yarn is 1.5cm; the weaving density of weft yarn is 65 threads / inch, in which 2 No. 2 yarns and 2 polyester composite filaments are alternately woven with warp yarn, No. 2 The yarn is formed by plying two polyester fiber and cotton fiber blended yarns with a thickness of 40 British counts, the blending ratio is 35wt% cotton and 65wt% polyester fiber, and the thickness of the polyester composite filament is 200D.

[0047] The tensile elastic elongation of the woven fabric provided by the present embodiment 1 is 22%, and the surface charge density is 4.2 μ С / m 2 .

Embodiment 2

[0049] In this embodiment, the weaving density of the warp yarns is 110 threads / inch, and the No. 1 yarn is a single yarn with a thickness of 20 lbs blended from polyester fibers and cotton fibers, and the blending ratio is 35wt% cotton and 65wt% Polyester fiber; antistatic yarn weaving spacing is 1.5cm; weft yarn weaving density is 65 / inch, in which 2 No. 2 yarns and 2 polyester composite filaments are alternately woven with warp yarns, No. 2 yarn It is formed by plying two polyester fiber and cotton fiber blended yarns with a thickness of 40 pounds, the blending ratio is 35wt% cotton and 65wt% polyester fiber, and the thickness of the polyester composite filament is 200D.

[0050] The tensile elastic elongation of the woven fabric provided by the present embodiment 2 is 21.5%, and the surface charge density is 4.5μС / m 2 .

Embodiment 3

[0052] In this embodiment, the weaving density of the warp yarns is 110 threads / inch, and the No. 1 yarn is formed by plying 2 polyester fibers with a thickness of 40 British counts and cotton fiber blended yarns, and the blending ratio is 35wt% cotton and 65wt% polyester fiber; the antistatic yarn weaving pitch is 1.5cm; the weaving density of the weft yarn is 65 / inch, wherein, 2 No. 2 yarns and 2 polyester composite filaments are woven alternately with the warp yarn, two The number yarn is made of polyester fiber and cotton fiber blended into a single yarn with a thickness of 20 pounds, the blending ratio is 35wt% cotton and 65wt% polyester fiber, and the thickness is 2 100D polyester composite filaments used in combination.

[0053] The tensile elastic elongation of the woven fabric provided by the present embodiment 3 is 21.2%, and the surface charge density is 4.3μС / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com