Split type deuterium-depleted water cup

A split-type, water cup technology, applied in water pollutants, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problem of high price, achieve the effect of fast precipitation rate, slow collision and recombination into water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

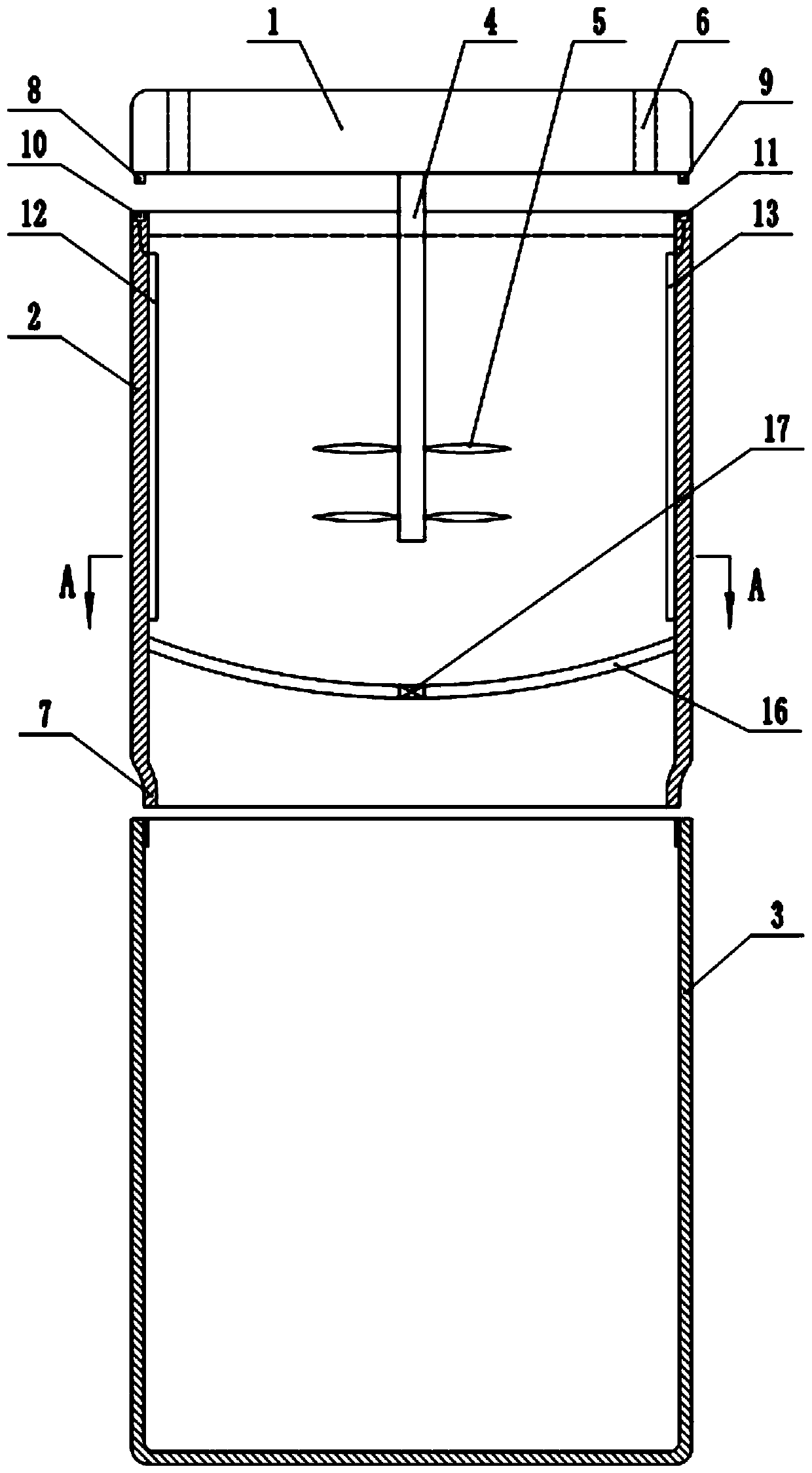

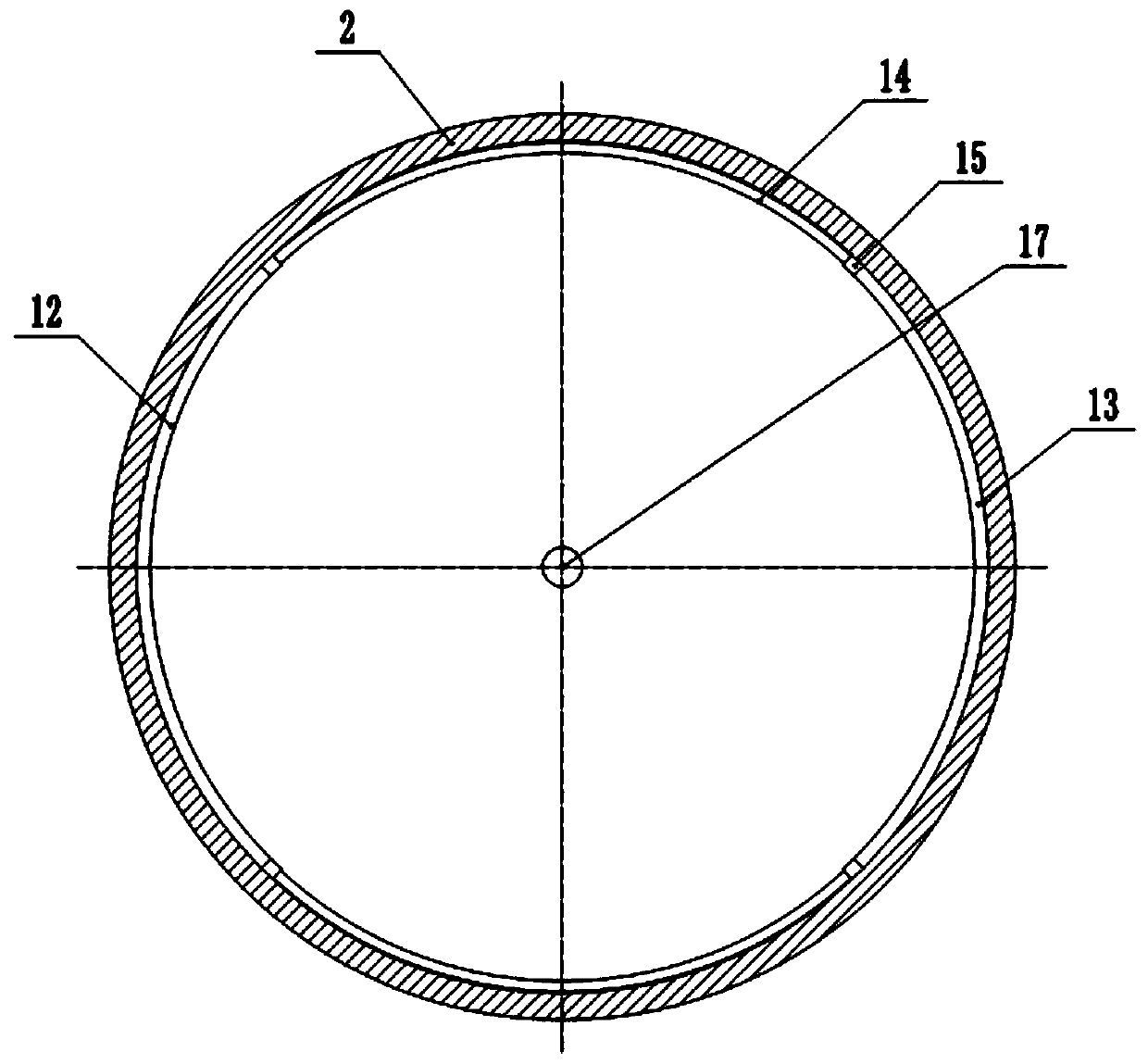

[0034] Embodiment 1 is basically as attached figure 1 and figure 2 Shown:

[0035] A split-type deuterium-depleted water cup, including a cup cover 1, an electrolytic cup 2 and a water storage cup 3, a stirrer is provided on the cup cover 1, an installation cavity is provided in the cup cover 1, and a DC power supply is provided in the installation cavity and a DC motor that drives the stirrer to rotate, wherein the stirrer includes a stirring rod 4 and a plurality of stirring blades 5, the stirring rod 4 is rotatably connected to the cup cover 1 and fixed with the output shaft of the DC motor, and the plurality of stirring blades 5 are fixed on the stirring On the rod 4, the stirring rod 4 and the stirring blade 5 in this embodiment are both made of food-grade insulating materials such as polypropylene.

[0036] There is an air vent 6 on the cup cover 1, and an insulating layer is wrapped on the outside of the cup cover 1, the electrolytic cup 2 and the water storage cup 3...

Embodiment 2

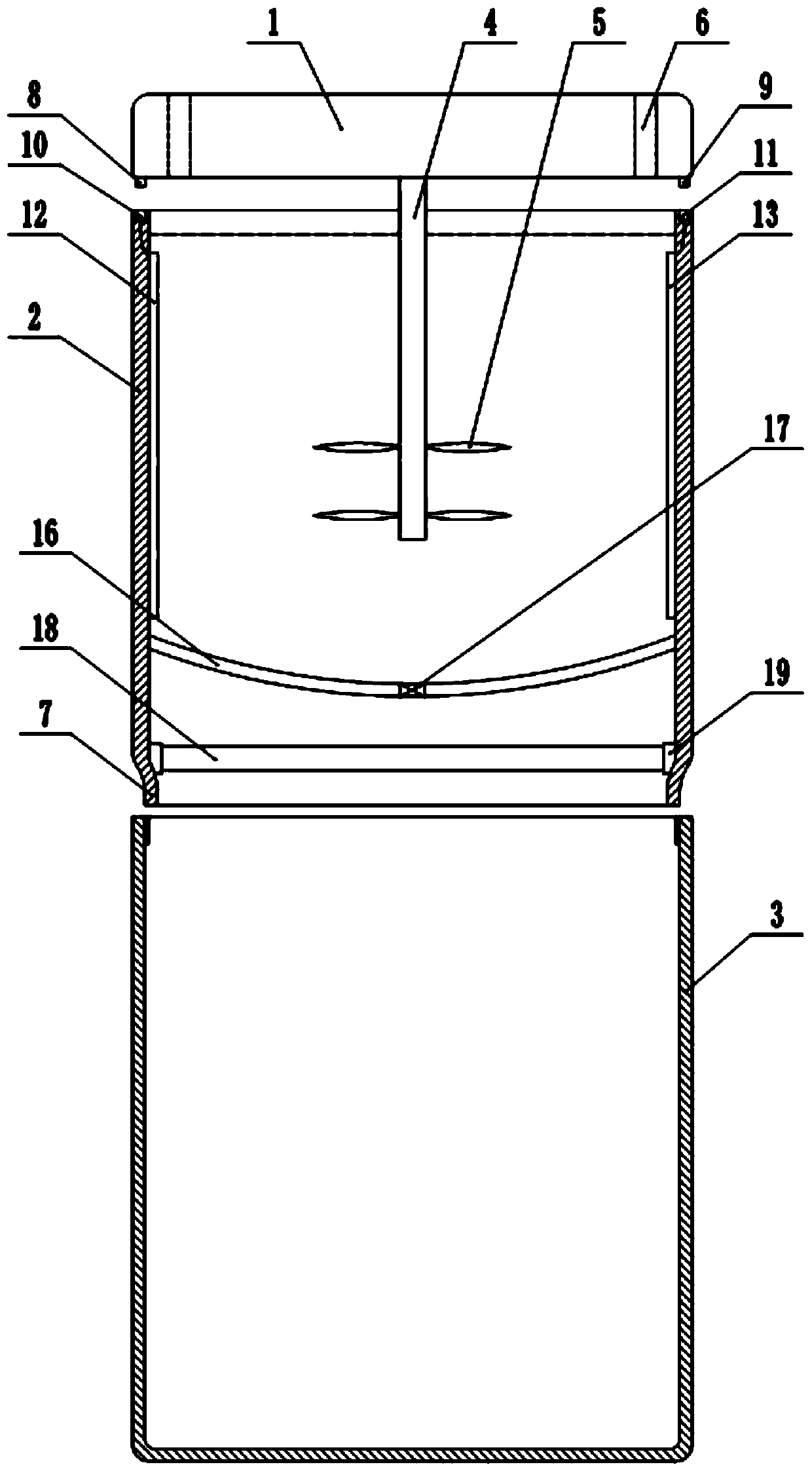

[0043] Embodiment 2 is basically as attached image 3 Shown:

[0044] The difference from Example 1 is that a secondary filter layer is detachably connected to the bottom of the electrolytic cup 2, the secondary filter layer includes a secondary adsorption plate 18, and the secondary adsorption plate 18 is disc-shaped, which is directly smaller than the external thread The inner diameter of the cylinder 7 is provided with a silicone ring 19 on the outer periphery of the secondary adsorption plate 18. The specific setting method is: a ring groove is opened on the inner side of the silicone ring 19, and the secondary adsorption plate 18 is stuck in the ring groove. In this embodiment, the second The material of the first-level adsorption plate 18 is the same as that of the first-level adsorption plate 14, which is one or more materials among quantum sieves, metal-organic framework materials (MOF), covalent organic framework materials (COF) or activated carbon materials. Since t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com