Top cover type hanging bracket device for hoisting prefabricated stand column reinforcement cage compound formwork

A steel cage and column technology, which is applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of the position conflict between the lifting point and the sling and the protruding steel bar, the deformation of the steel cage and the template is not easy to control, and the operation is inconvenient. To achieve the effect of increasing rigidity, high rigidity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

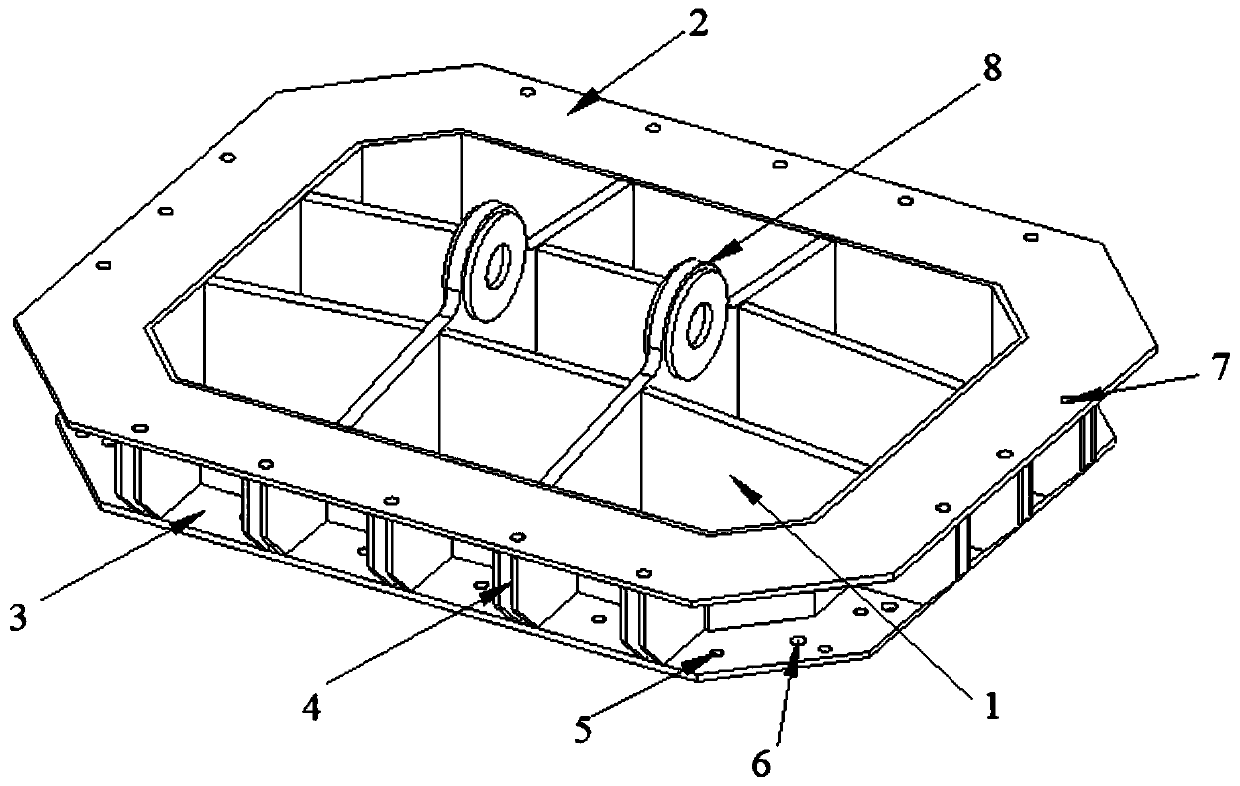

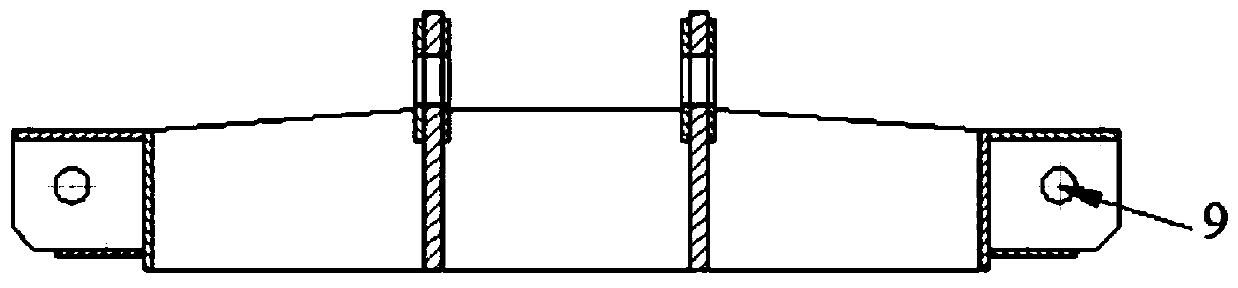

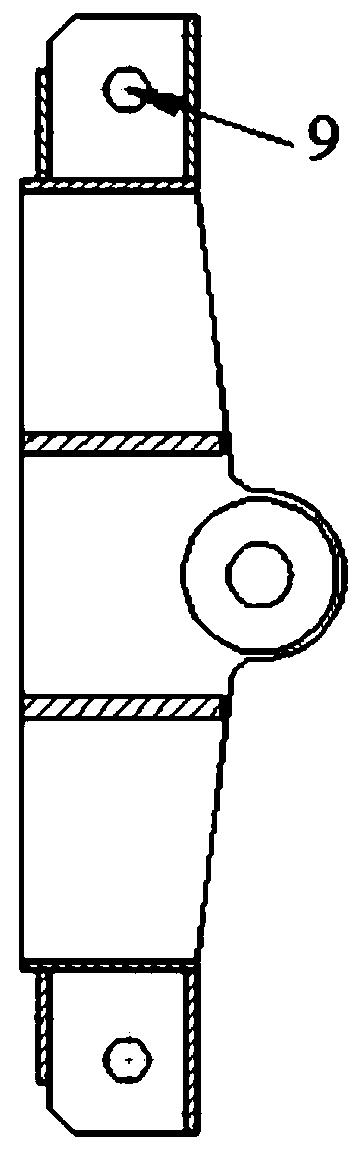

[0047] Such as figure 1 Shown is a three-dimensional structural schematic diagram of a roof-type hanger device used for prefabricated column steel cage mold clamping and lifting according to an embodiment of the present invention, as figure 2 shown as figure 1 sectional view, such as image 3 shown as figure 1 front view, such as Figure 4 shown as figure 1 side view.

[0048] Please refer to Figure 1-4 , the hanger device of this embodiment is a hollow frame structure, which is used to cover the upper part of the prefabricated column reinforcement cage when the prefabricated column reinforcement cage is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com