A sound-absorbing structure for an air supply duct of a rail vehicle

A technology for rail vehicles and air supply ducts, which is applied in the field of rail vehicle air conditioning systems, can solve the problems that the air ducts are not silenced or soundproofed, are not suitable for occasions with high sound requirements, and the wind fluctuates with large noise, achieving obvious effects and reducing the cost , the effect of reducing the vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

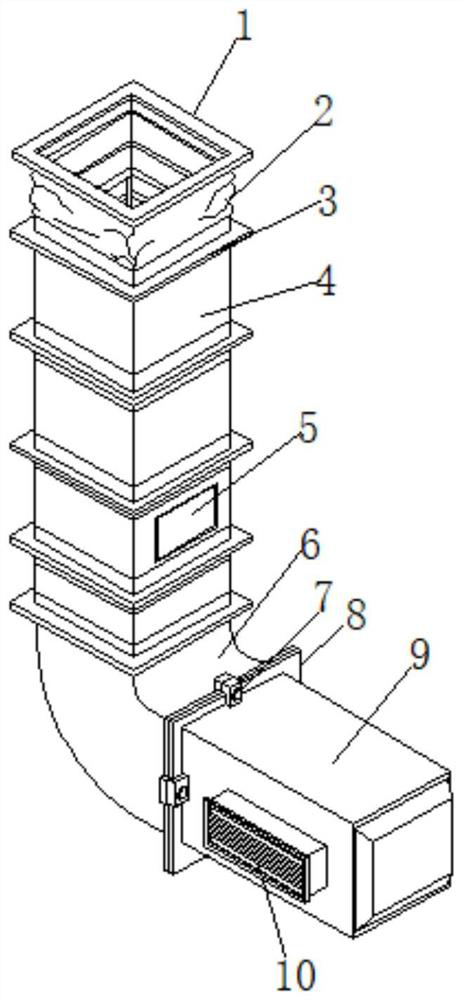

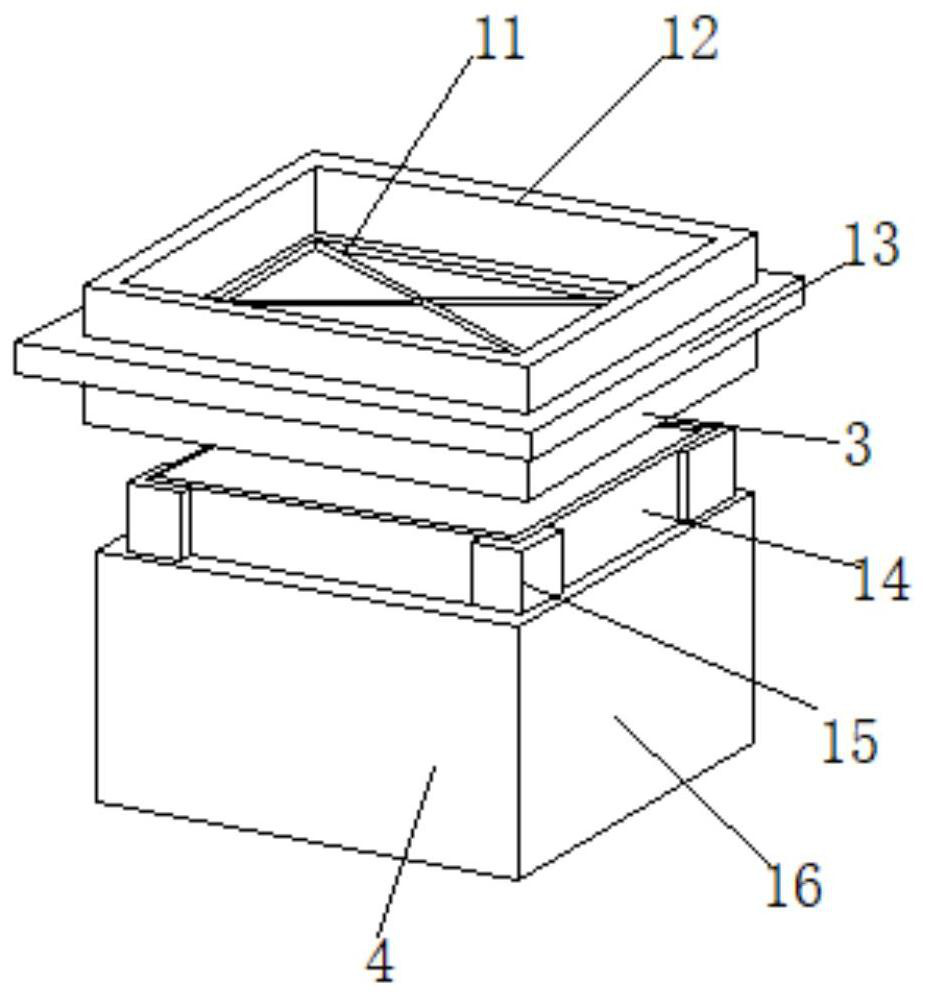

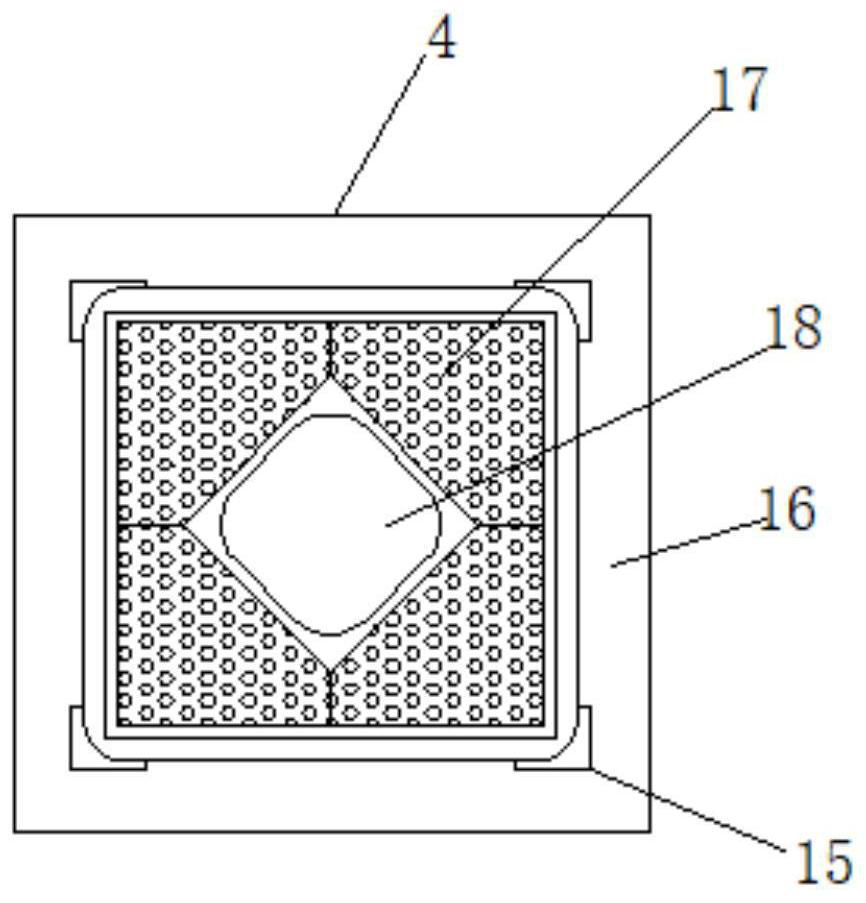

[0028] refer to Figure 1-4 , a rail vehicle air supply channel noise reduction structure, including an air inlet flange 1, the outer wall of the bottom end of the air inlet flange 1 is socketed with a flexible pipe 2, and the outer wall of the bottom end of the flexible pipe 2 is socketed with a connecting flange 3 , the outer wall of the bottom end of the connecting flange 3 is sleeved with an air duct pipe 4, and the number of the air duct pipe 4 is at least two, and the opposite ends of the two air duct pipes 4 are fixed by the connecting flange 3, and the air duct The outer wall of the bottom end of the duct 4 is connected with a connecting elbow 6, and the end of the connecting elbow 6 is provided with a pressing flange 8, and the connecting elbow 6 is fixedly connected with an air outlet pipe 9 through the pressing flange 8, and the air outlet pipe 9 The middle part of one side of the outer wall is provided with an air outlet fan 10, and the middle part of one side of t...

Embodiment 2

[0031] refer to Figure 5 , a rail vehicle air supply duct noise reduction structure, the main difference between this embodiment and embodiment 1 is that in this embodiment, it also includes a frequency sensor 23, an electromagnetic driver 22 and a vibrating membrane 21, and the frequency sensor 23 is fixedly connected to the outlet The air duct 9 is close to the inner wall of one end of the pressing flange 8, and the output end of the electromagnetic driver 22 is fixedly connected to the outer wall of one side of the vibrating membrane 21, and the other side of the vibrating membrane 21 is arranged on the inner wall of the end of the cavity. Both the driver 22 and the blower fan 10 are connected with a switch, and the switch is connected with a PLC controller through wires.

[0032]The working principle of this embodiment: based on the working principle in Embodiment 1, wherein an active interference device is provided in the air outlet pipe, the frequency sensor 23 senses t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com