Polymeric proppant automatic lifting dry and wet screening device and method

An automatic lifting and screening device technology, which is applied in the field of oil production engineering, can solve the problems of inability to accurately characterize the sieving distribution of polymeric proppants, etc., achieve good technical support, wide application range, and solve the effect of strong static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056]In order to make the purpose, technical features and technical effects of the technical solution of the present invention more clear, the exemplary solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings of specific embodiments of the present invention.

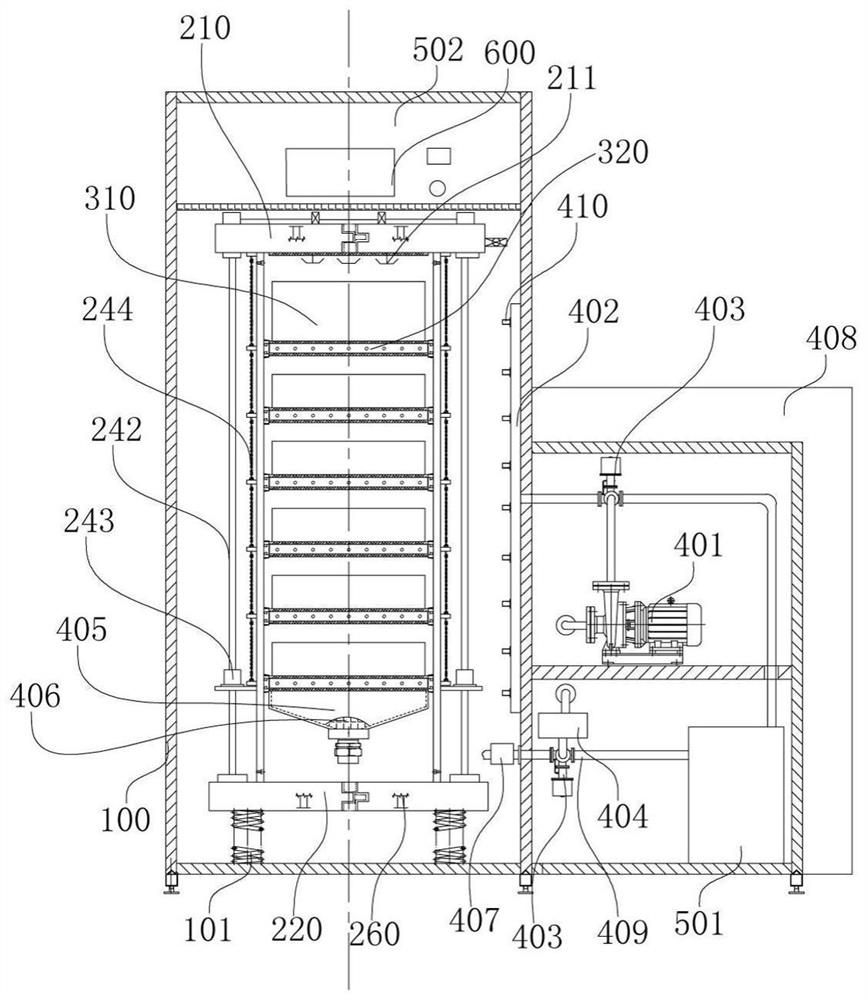

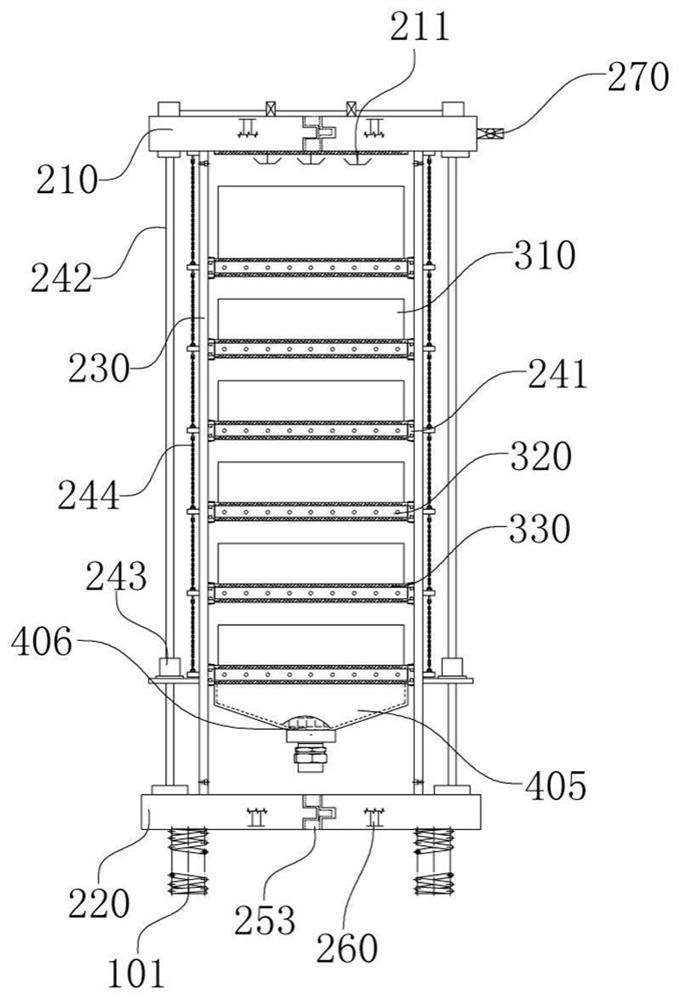

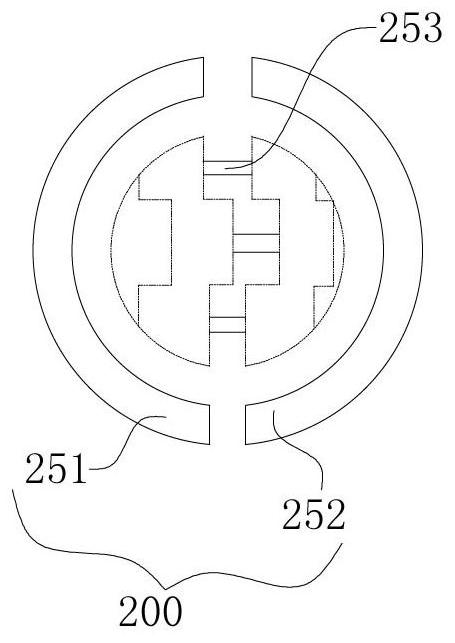

[0057] See attached figure 1 - attached Figure 4 , this application discloses a polymeric proppant automatic lifting dry and wet screening device, including a housing 100, a supporting frame 200, a vibrating screen 310, a water spray belt 320, a lifting component 240, a water supply component, a drying component and a control System 600, the support frame 200 is set in the housing 100 through elastic components, and the vibrator 260 is arranged on the support frame 200, and the sprinkler head 211 is arranged on the top of the support frame 200; Groups of vibrating screens 310 are stacked in the supporting frame 200, and the apertures of mult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com