Intelligent automatic cream processing equipment

A processing equipment and cream technology, applied in the protein composition of eggs, food science, protein food composition, etc., can solve the problems of perishability, slow operation of egg white and egg yolk, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

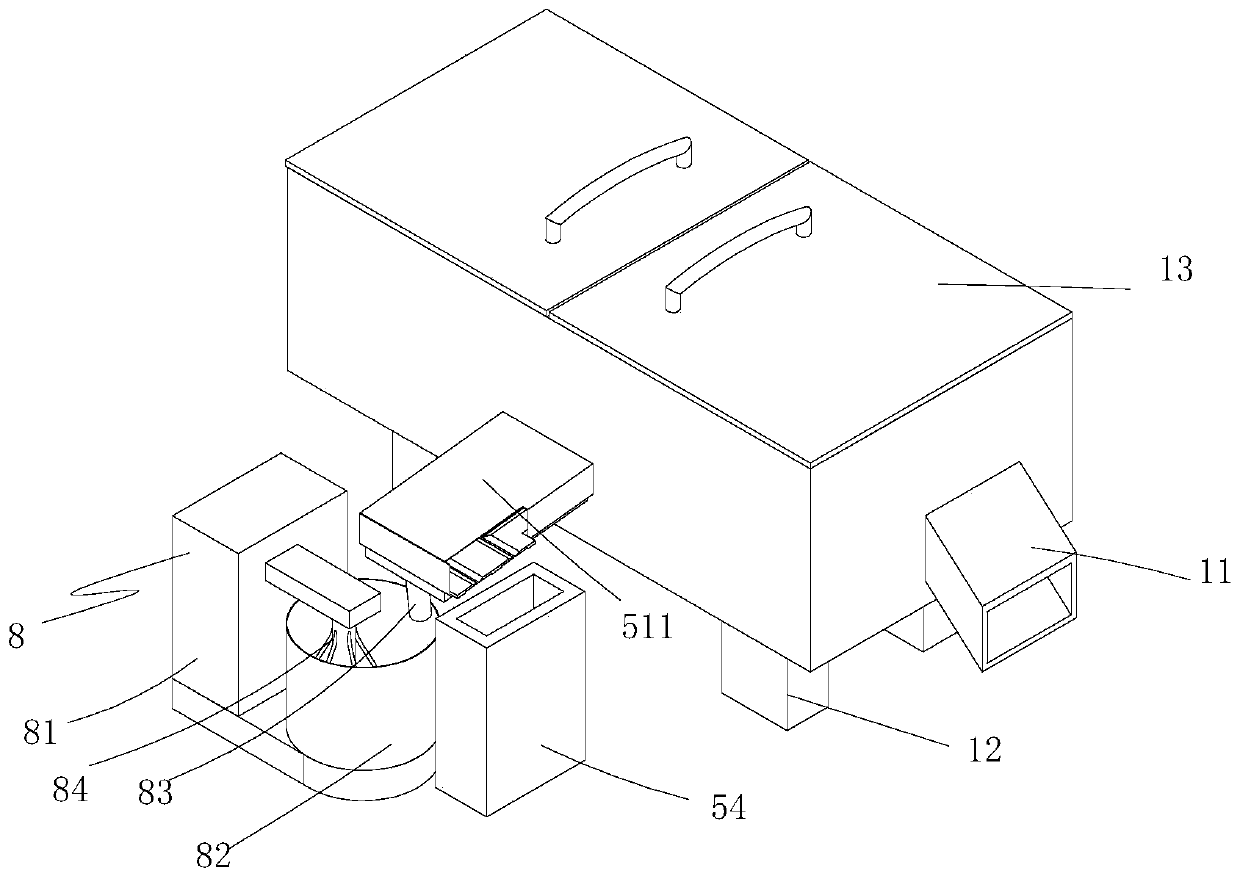

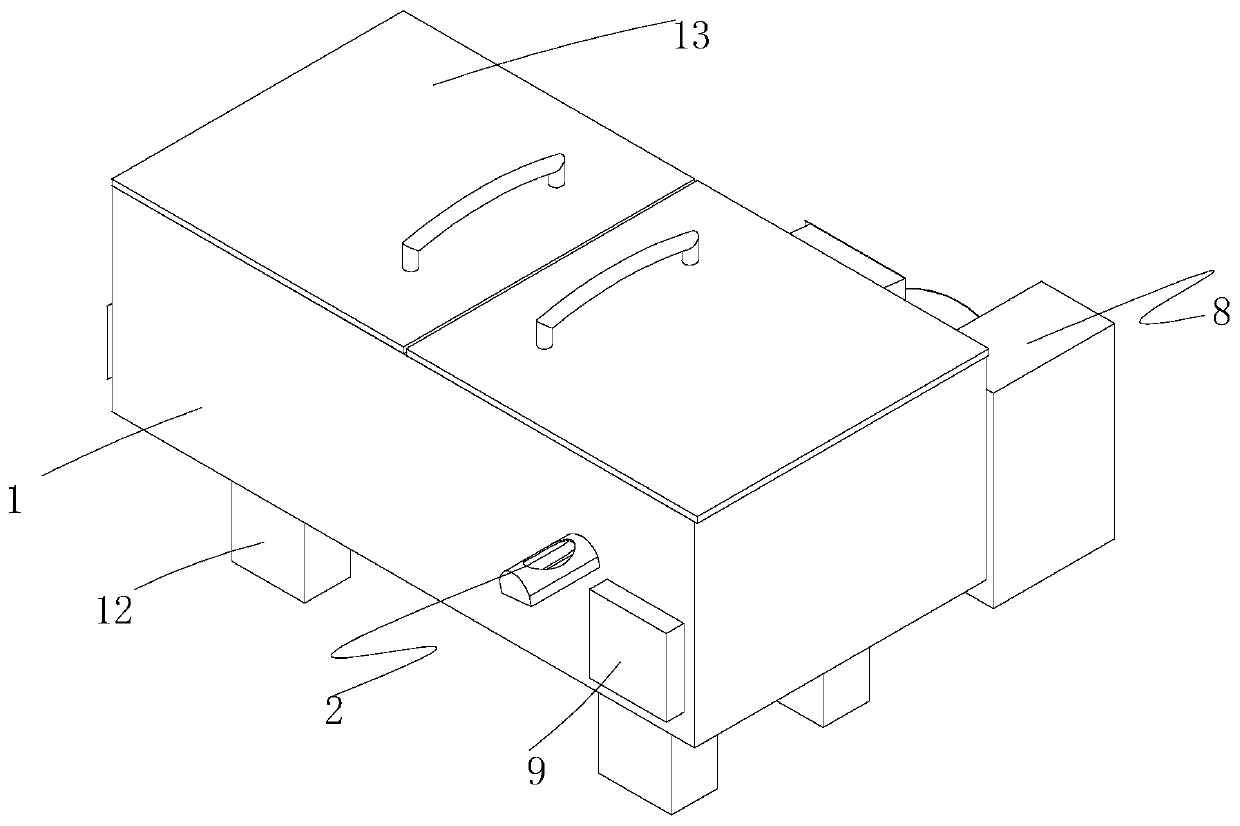

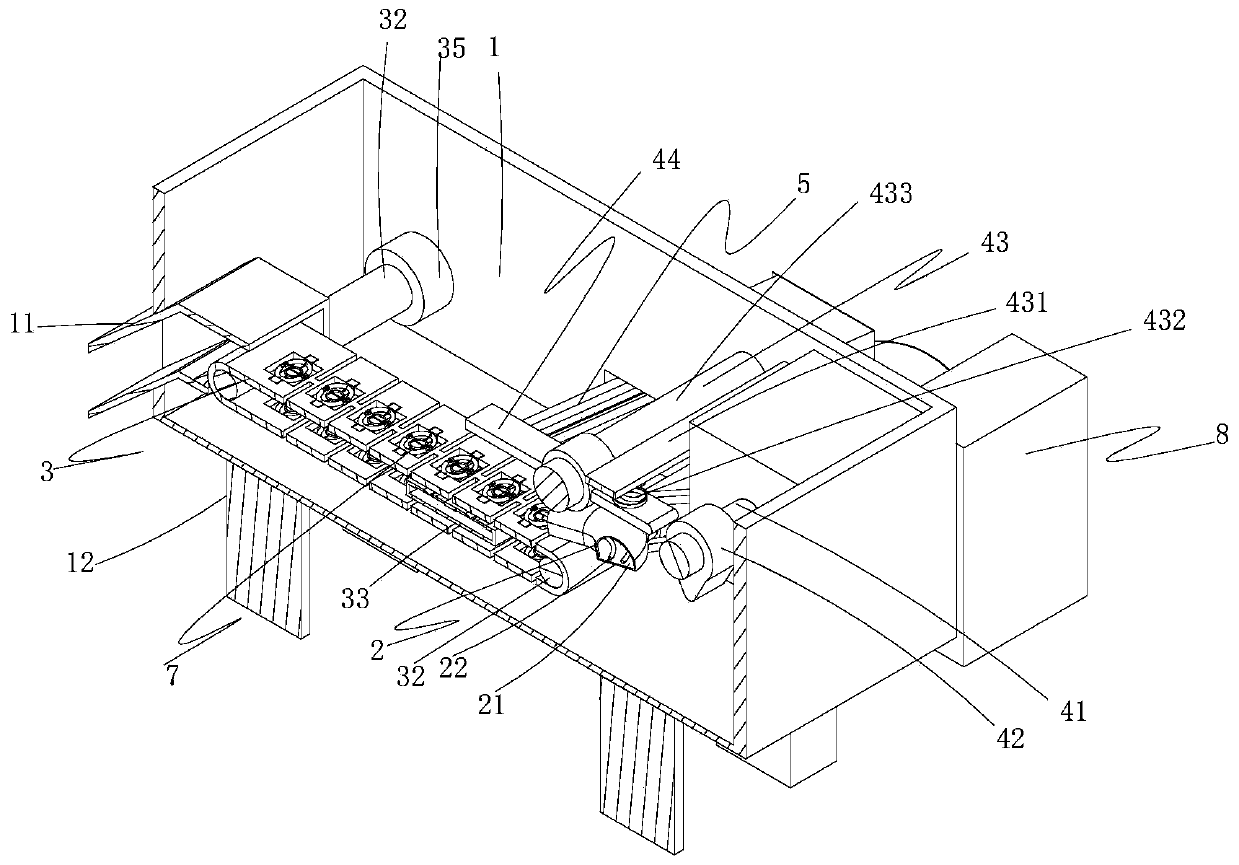

[0029] Such as Figure 1-13 As shown, an intelligent automatic butter processing equipment includes a machine body 1, a feeding channel 2, a conveying device 3, a shell breaking device, a material guiding device 5 and a driving part 6; specifically, the driving part 6 is a frequency conversion device that can be purchased directly on the market. The motor is not described in detail here, and the driver 6 is located in a casing; the shell breaking device includes a rotating shaft 41 partially pierced outside the casing, a cam 42 located on the rotating shaft 41, a positioning member 43, a broken shell 44 and A plurality of position-limiting parts 7; the conveying device 3 includes a first round roller 31, a second round roller 32, a transmission part 33 and a transmission part 34, and the first and second round rollers are rotating shafts with bearings 35 at both ends, and The first and the second are rotating shafts of the same size and model, and the first and second round ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com