Feed feeding device for livestock breeding

A feed and crushing device technology, which is applied in the field of animal husbandry, can solve the problems of unsuitable feed, unfavorable growth of livestock, and the amount of feed that livestock do not eat, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

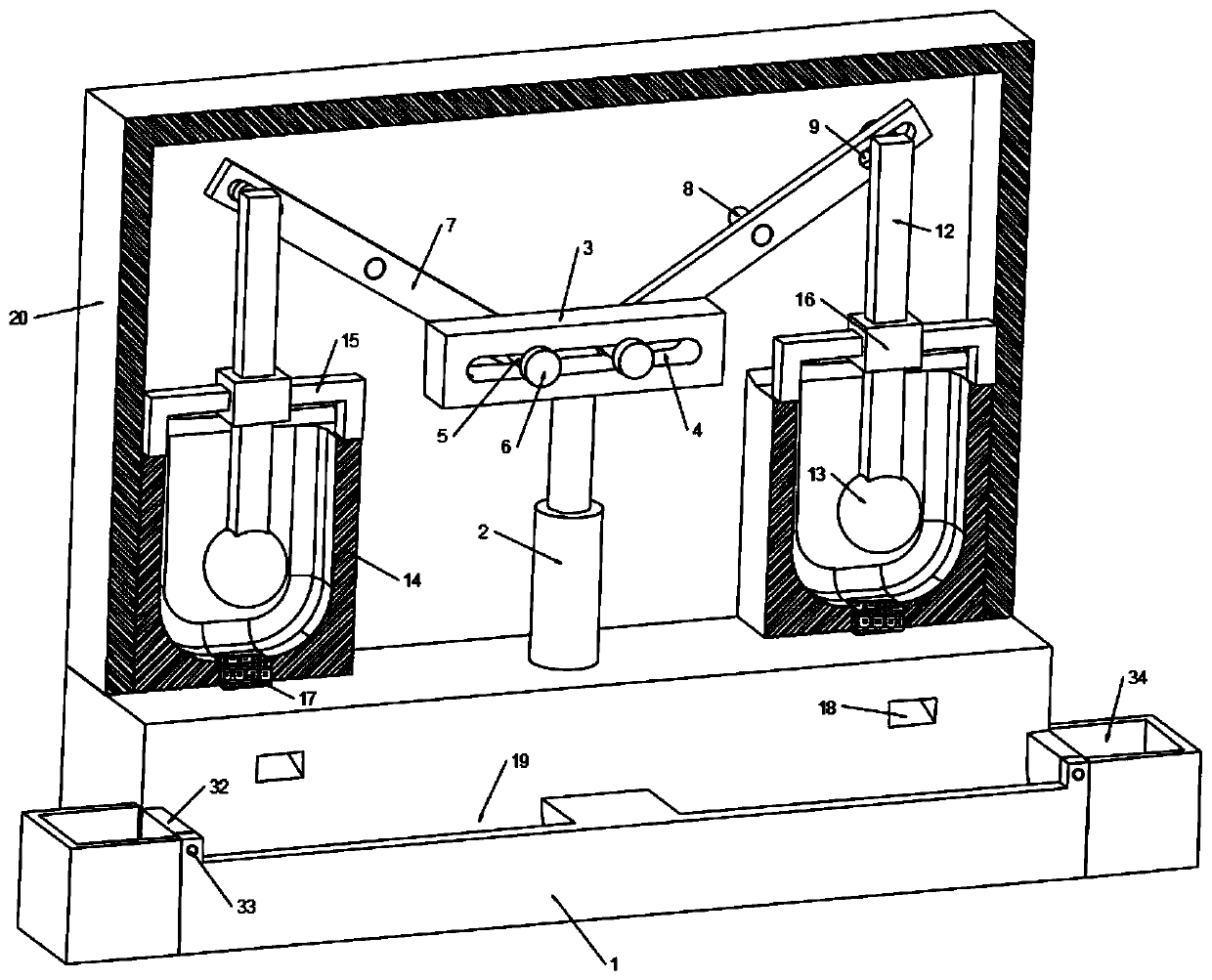

[0022] see Figure 1-5 , in an embodiment of the present invention, a feed feeding device for animal husbandry, comprising a base 1, the upper end of the base 1 is provided with a casing 20, the inside of the casing 20 is provided with a telescopic rod 2, and the lower end of the telescopic rod 2 is fixedly connected to the upper end of the base 1 , the upper end of the telescopic rod 2 is fixedly connected with a moving block 3, the middle part of the moving block 3 is provided with a groove 4, two fixed rods 5 are slidably installed in the groove 4, one end of the fixed rod 5 is fixedly connected with a boss 6, and the other end Rotatingly connected with a rotating rod 7, the middle part of the rotating rod 7 is rotatingly connected with a rotating shaft 8, and the end of the rotating shaft 8 is rotatingly connected on the inner wall of the housing 20, and the end of the rotating rod 7 away from the fixed rod 5 is provided with a chute 9, which slides A connecting rod 10 is ...

Embodiment 2

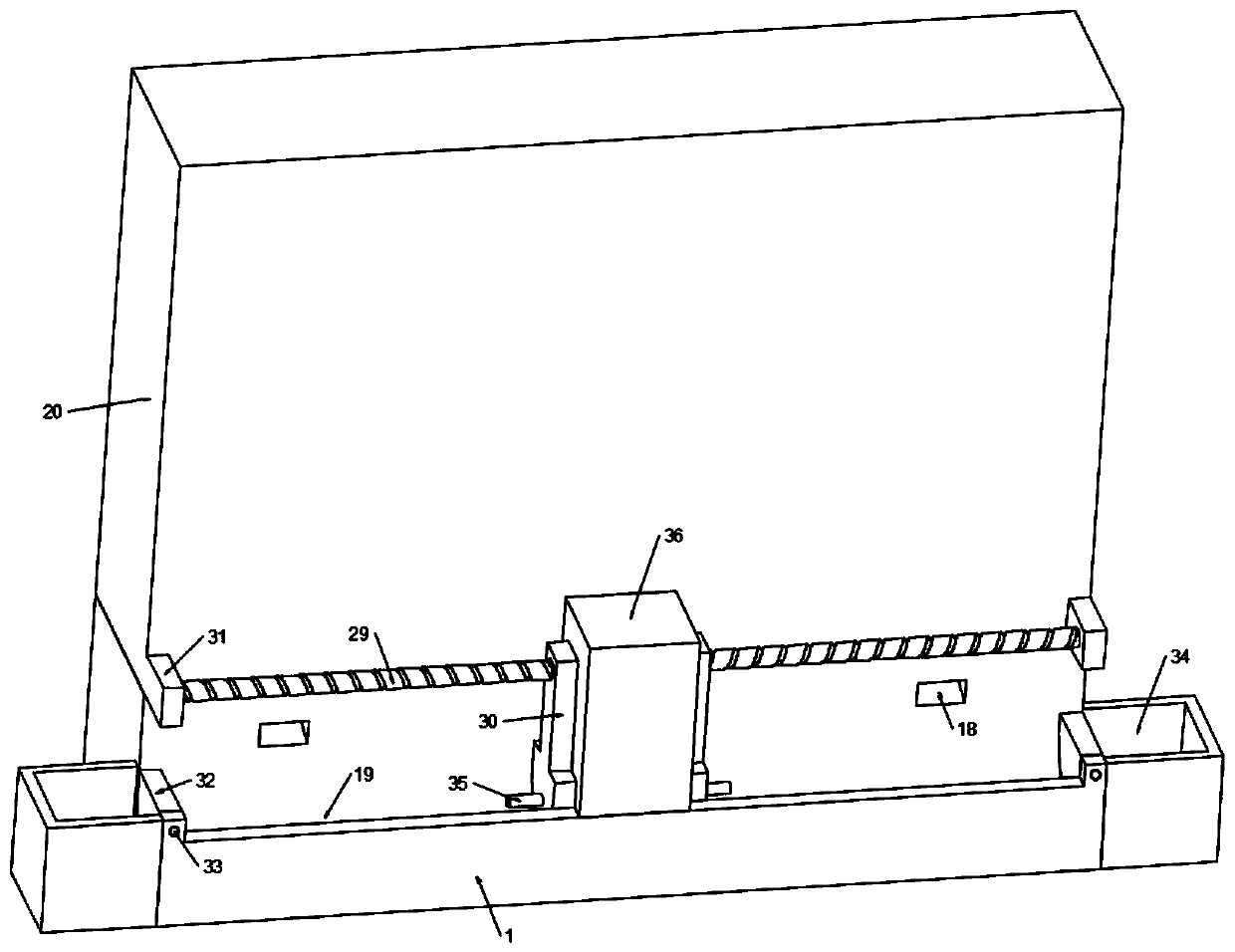

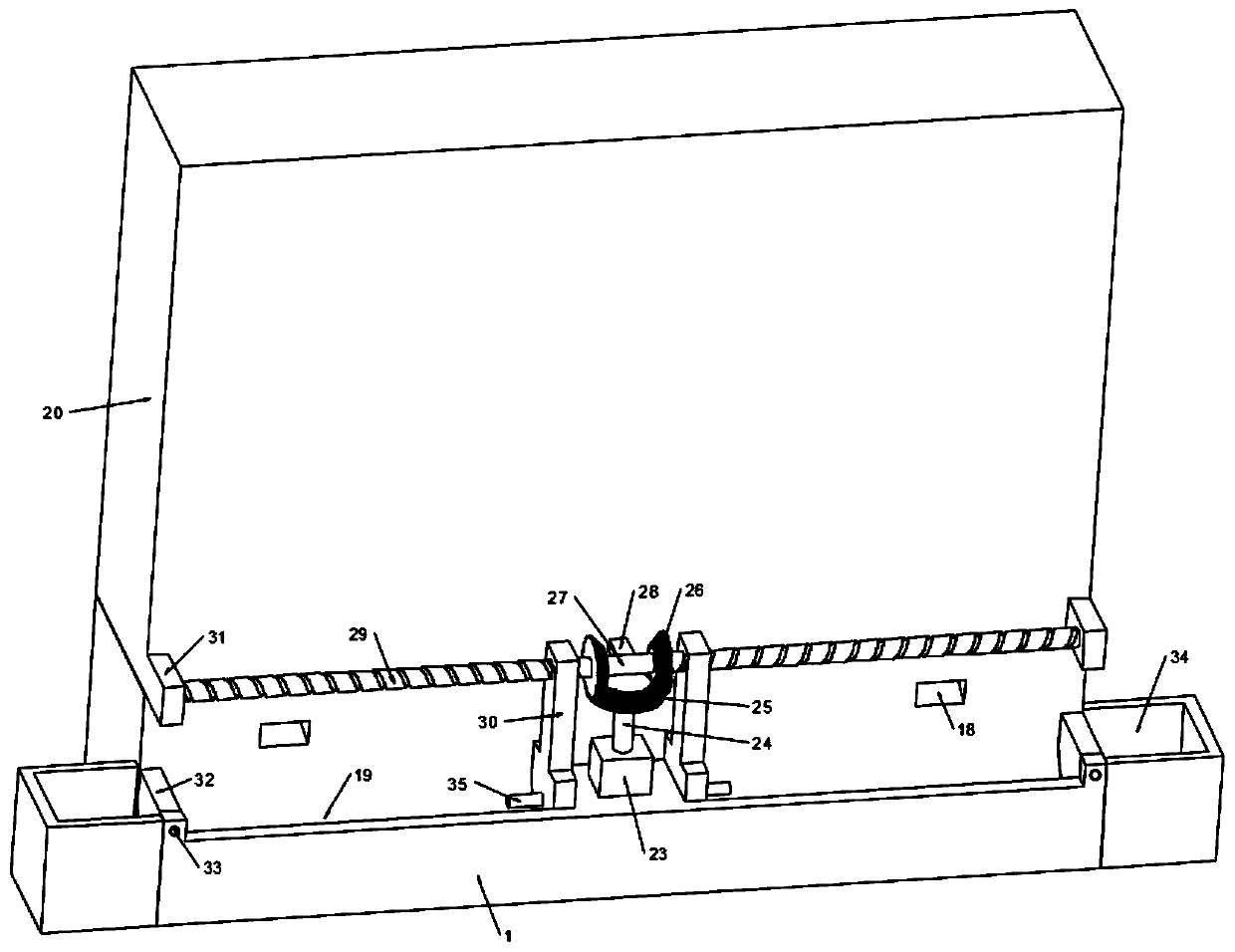

[0030] In order to prevent the bevel gear 1 25 and the bevel gear 2 26 from causing harm to livestock, this embodiment is further improved on the basis of embodiment 1. The improvement is: the upper end of the base 1 is provided with a protective cover 36, and the protective cover 36 is located on the motor. 23 outside, by setting protective cover 36, motor 23, bevel gear one 25 and bevel gear two 26 can be wrapped up, prevent it from hurting livestock, improve the safety of this device.

[0031] The working principle of this embodiment is: in order to prevent the first bevel gear 25 and the second bevel gear 26 from causing damage to livestock, a protective cover 36 is provided on the upper end of the base 1, and the protective cover 36 is located outside the motor 23. By setting the protective cover 36, Motor 23, bevel gear one 25 and bevel gear two 26 can be wrapped to prevent it from injuring livestock and improve the safety of the device.

[0032] To sum up, by setting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com