Method for determining content of dimethyl sulfoxide in sample in purification process

A technology of dimethyl sulfoxide and purification process is applied in the field of carbon fiber solvent recovery to achieve the effect of saving detection cost and shortening detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for determining the content of dimethyl sulfoxide in a purification process sample, comprising the following steps:

[0024] (a) Select coagulation bath sample solutions with different concentrations at the positions of the first, second and third bath coagulation baths after 2 days of normal production in the polyacrylonitrile-based carbon fiber spinning process, and use the iodometric method to titrate the dimethyl methoxide in the sample solution respectively. The content of sulfone, obtain the sample solution of known dimethyl sulfoxide content;

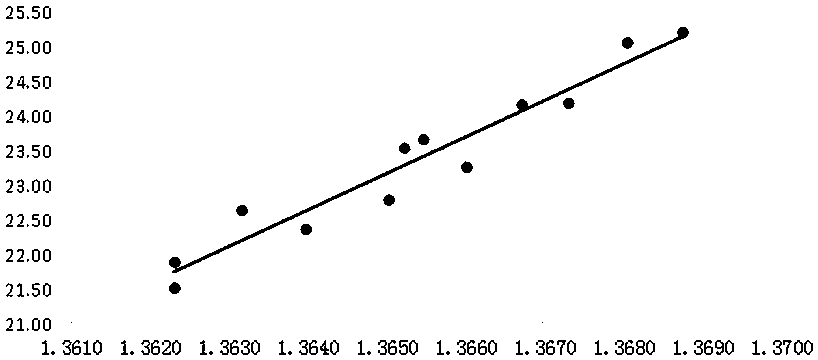

[0025] (b) Use the sample solution with known dimethyl sulfoxide content in step (a) to prepare dimethyl sulfoxide solutions with different contents, and use a refractive index meter to measure the refractive index of the prepared dimethyl sulfoxide solutions with different contents , draw the corresponding curve of the refractive index and the content of dimethyl sulfoxide, as a standard curve;

[0026] (c) Take...

Embodiment 2

[0029] Using the same steps as in Example 1, test the crude product tower top sample in the purification process of dimethyl sulfoxide, and titrate the dimethyl sulfoxide content with iodometric method to be 75.88%, and record the refractive index of the sample at the same time as 1.44978, drawing The corresponding curve of refractive index and dimethyl sulfoxide content at the crude product tower top position is as follows figure 2 As shown, the dimethyl sulfoxide content was found to be 75.44% on the standard curve.

Embodiment

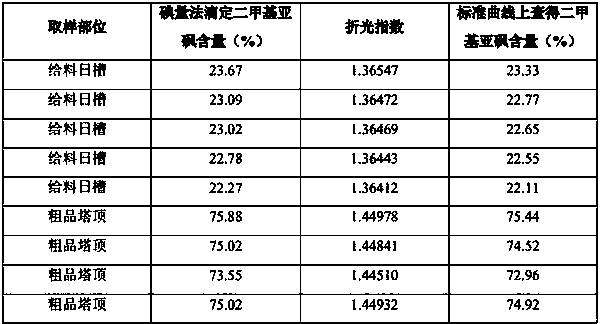

[0030] Example data comparison:

[0031]

[0032] Conclusion: As can be seen from the above table, the content of dimethyl sulfoxide in the samples taken from the feed tank and the top of the crude product tower during the purification process measured by this method is compared with the value obtained by iodometric titration analysis. In comparison, the relative error is in the range of 1 to 2%. The same sample takes about 2 hours to be titrated by the traditional iodometric method, but it only takes about 5 minutes to use this method; this method can quickly determine dimethyl methylene During the sulfone purification process, the content of dimethyl sulfoxide in the samples taken from the feed tank, the top of the crude product tower, etc., and the determination results are accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com