A hot rolling roller for asphalt road construction

A technology of road construction and hot rolling, which is applied in the field of hot rolling drums, can solve problems such as environmental pollution, high temperature of hot rolling drums, and low safety factor of charcoal, so as to increase storage space, reduce replacement frequency, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

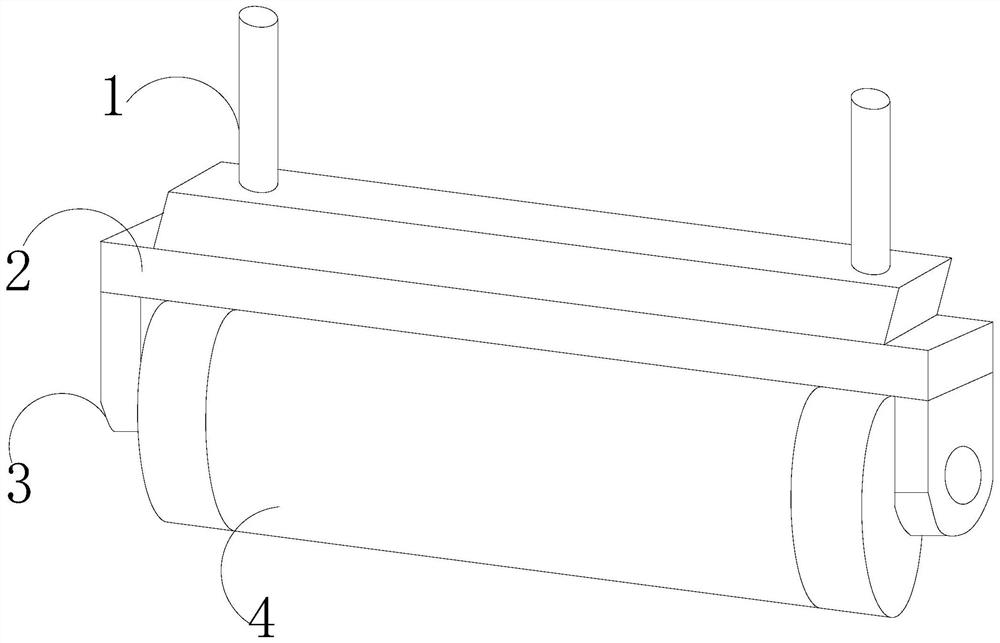

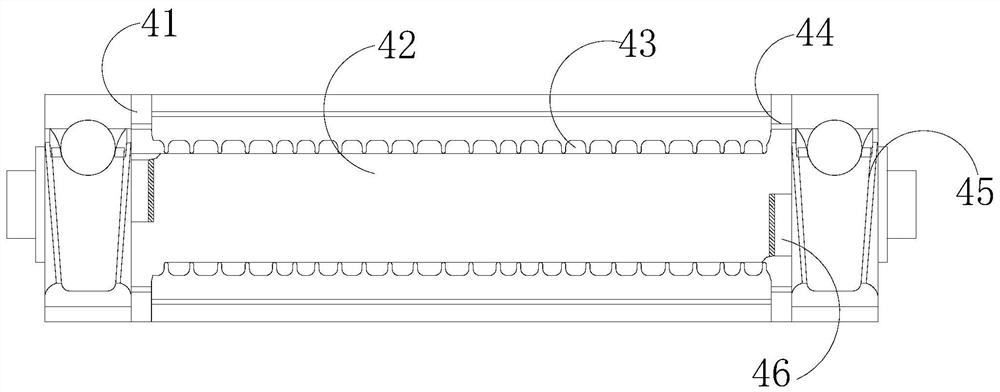

[0032] Such as Figure 1-Figure 4 As shown, the present invention provides a hot rolling roller for asphalt road construction. Its structure includes a vertical rod 1, an installation frame 2, a fixed head 3, and a cylinder body 4. The cylinder body 4 is mechanically connected by the fixed head 3 and the installation frame 2 The installation frame 2 is installed on the walking device through the two vertical poles 1 vertically fixed on the upper end, and the cylinder body 4 includes a feeding port 41, a heating core 42, a cooling hole 43, a discharge port 44, and a collector. Material mechanism 45, self-propelled scraper 46, described feeding port 41 and discharging port 44 are communicated with heating core 42, and described heating core 42 is provided with more than two cooling holes 43, on described heating core 42 A slideway cooperating with the self-propelled scraper 46 is provided, and the self-propelled scraper 46 is horizontally movable and matched with the discharge p...

Embodiment 2

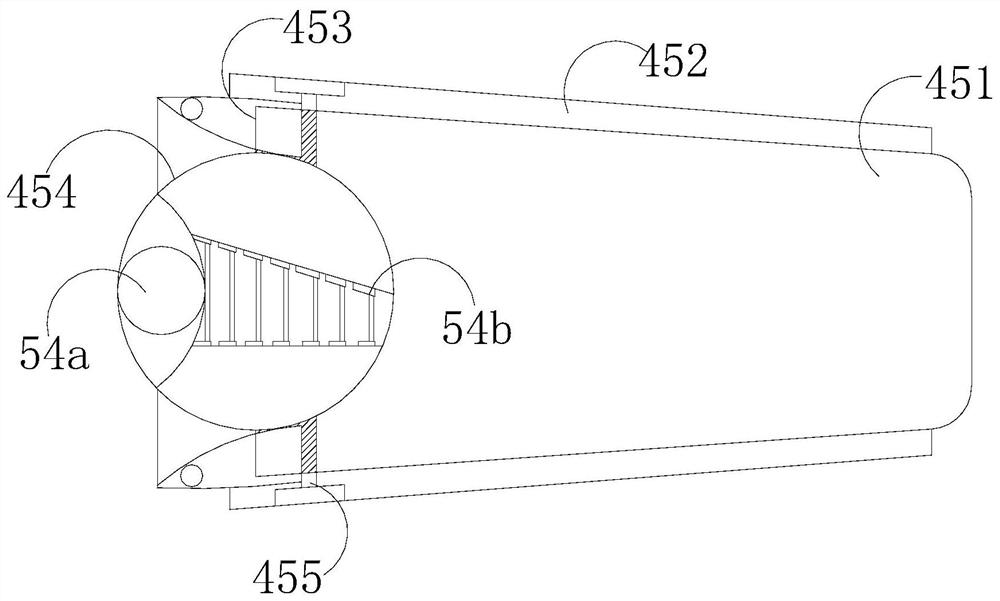

[0039] Such as Figure 5-Figure 7 As shown, on the basis of Embodiment 1, through the mutual cooperation of the following structural components, the air guide mechanism 54c includes an air pump c1 and an air delivery pipe c2, the gas outlet of the air pump c1 is connected to the air delivery pipe c2, and the air delivery pipe There are more than two c2, which are connected to the crushing chamber 54b in an arched shape.

[0040] The crushing cavity 54b includes a support plate 4b1, a slide bar 4b2, and a broken block 4b3. The inside of the support plate 4b1 is fixed with a slide bar 4b2. Both ends of the slide bar 4b2 are respectively provided with a broken block 4b3. 4b3 moves in the same direction along the slide bar 4b2 to change the spacing, thereby realizing the crushing effect on the charcoal output from the discharge port 54a.

[0041] The broken block 4b3 is equipped with a sealed air bag b31, and more than two barbs b32 are densely covered on the surface of the broke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com