Self-adhesive label pasting system and pasting method

A label, number one technology, applied in the field of self-adhesive label posting systems, which can solve problems such as difficult identification, blade deflection, and label wrinkling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

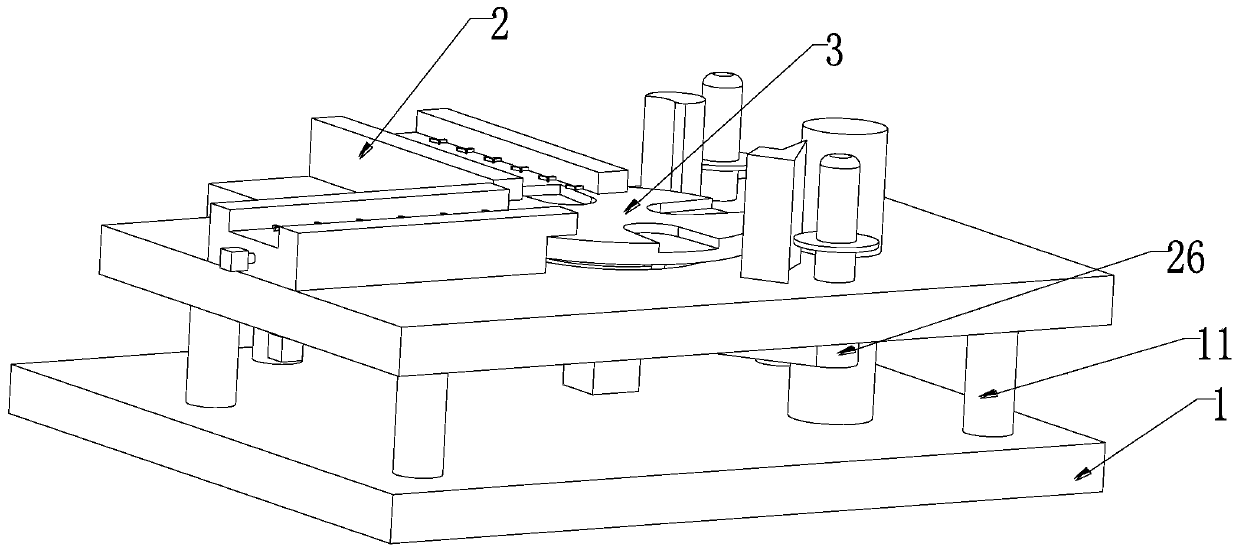

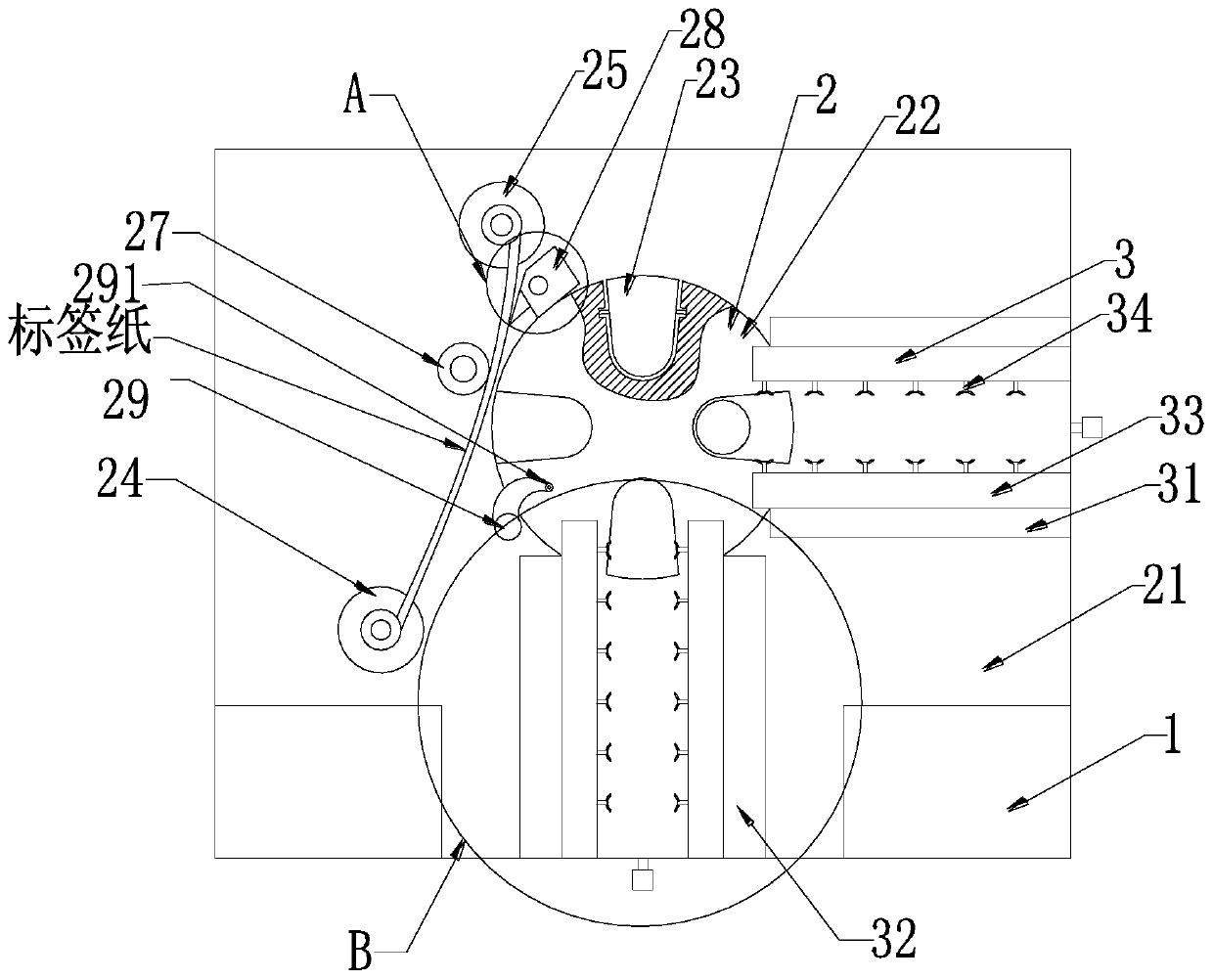

[0031] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 7 , to further elaborate the present invention.

[0032] A self-adhesive label posting system, comprising a mounting plate 1, a sticking set 2 and a conveying set 3, the mounting plate 1 is evenly installed with a support column 11 by welding, the support column 11 is provided with a sticking set 2, the sticking set 2 The outside is provided with delivery kit 3, wherein:

[0033]The paste kit 2 includes a working platform 21, a No. 1 motor, a rotating plate 22, a supporting slide 23, a feeding column 24, a roll paper column 25, a transmission belt 26, a material resisting roller 27, a scraper knife 28 and a smoothing frame 29 , the working platform 21 is fixedly installed on the support column 11 by welding, a No. 1 motor is installed on the motor base of the working platform 21, and a rotating pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com