Dual iron plate machining folding device

A kind of iron sheet and double technology, which is applied in the field of double sheet metal sheet processing half-folding device, can solve the problems that the sheet metal sheets of different widths cannot be folded in half, the folding efficiency is slow, and the folding is difficult, so as to improve the folding efficiency of processing, reduce labor intensity and facilitate Organize collection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

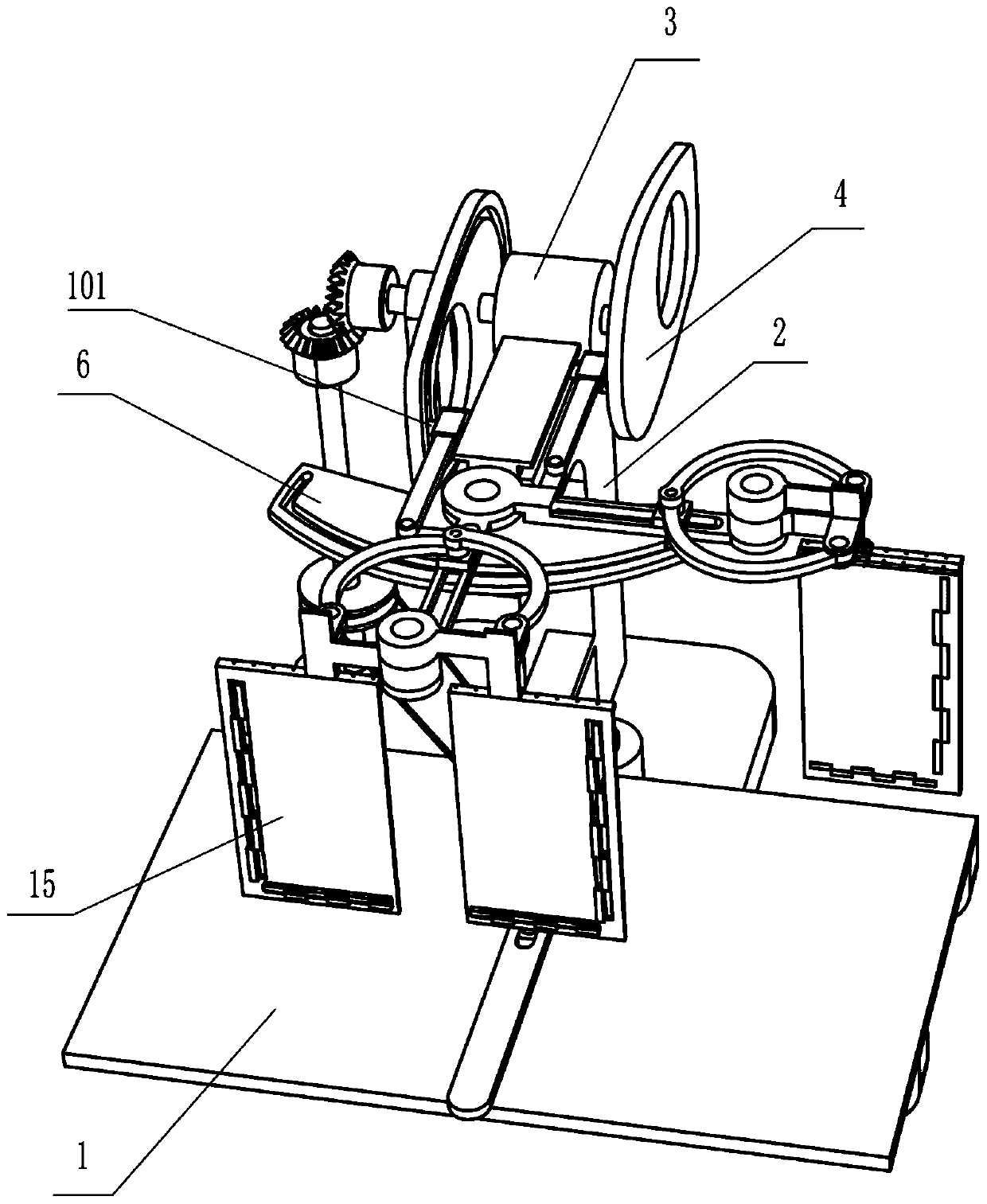

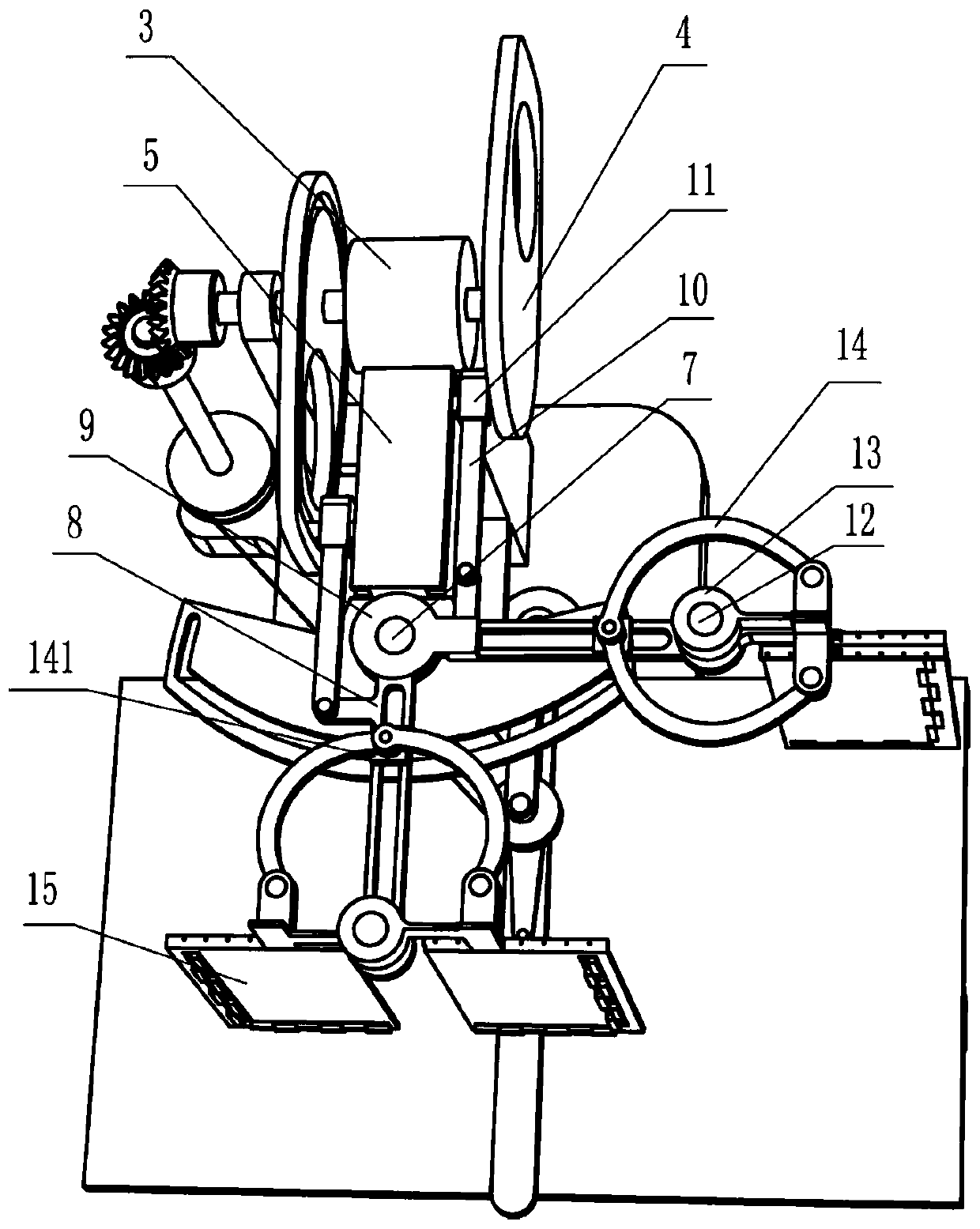

[0017] Embodiment: a kind of double iron plate processing folding device, such as Figure 1-5 As shown, it includes base plate 1, support 2, biaxial motor 3, convex plate 4, slide rail 5, slideway 6, rotating shaft one 7, straight board one 8, straight board two 9, rotating shaft 101, connecting Rod 10, guide sleeve 11, turning device and adjusting device, the lower end of the support 2 is fixedly installed on the base plate 1, the biaxial motor 3 is fixedly installed on the support 2, and the two convex plates 4 are respectively fixed Installed on the two output shafts of the biaxial motor 3, the slide rail 5 is fixedly mounted on the support 2 and positioned in front of the biaxial motor 3, the slideway 6 is fixedly mounted on the support 2 and the rear end is connected to the slide rail 5 The front side is connected, the lower end of the rotating shaft one 7 is fixedly installed on the slideway 6, the said flat plate one 8 is rotatably installed on the rotating shaft one 7,...

Embodiment approach

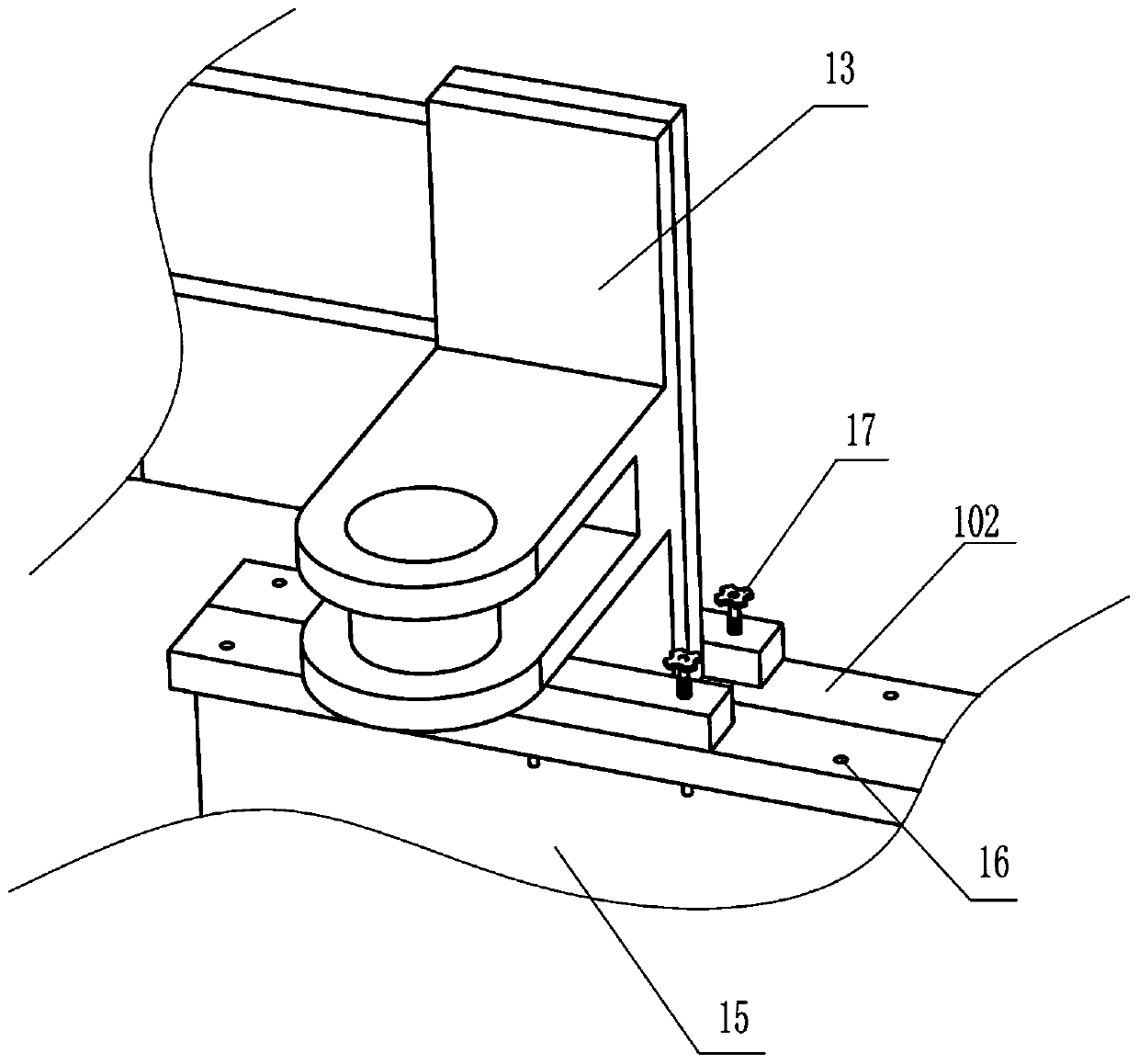

[0019] In a specific embodiment provided by the present invention, the adjustment device includes a screw 17 and an orifice 102, and one end of the splint 15 is equipped with an orifice 102, and eight screw holes 16 are opened on the orifice 102. The orifice plate 102 is connected to the first mounting plate 13 through screw holes 16 and screws 17 .

[0020] In a specific embodiment provided by the present invention, one side of the splint is equipped with twelve long strip protrusions for supporting and placing the iron sheet, and the twelve long strip protrusions are arranged in an L shape, which is convenient for long Placement and folding of iron sheets.

[0021] A specific embodiment provided by the present invention also includes an oscillating device that pushes away and completes the folding of the iron sheet. The oscillating device includes a rotating shaft three 18, a first bevel gear 19, a rotating shaft four 20, a second bevel gear 21, a second One pulley 22, rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com