PE pipe fitting machining equipment

A technology for processing equipment and pipe fittings, which is applied in the field of PE pipe fittings processing equipment, can solve problems such as difficult construction, and achieve the effect of ensuring the bonding effect, accurate glue position, and relative position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

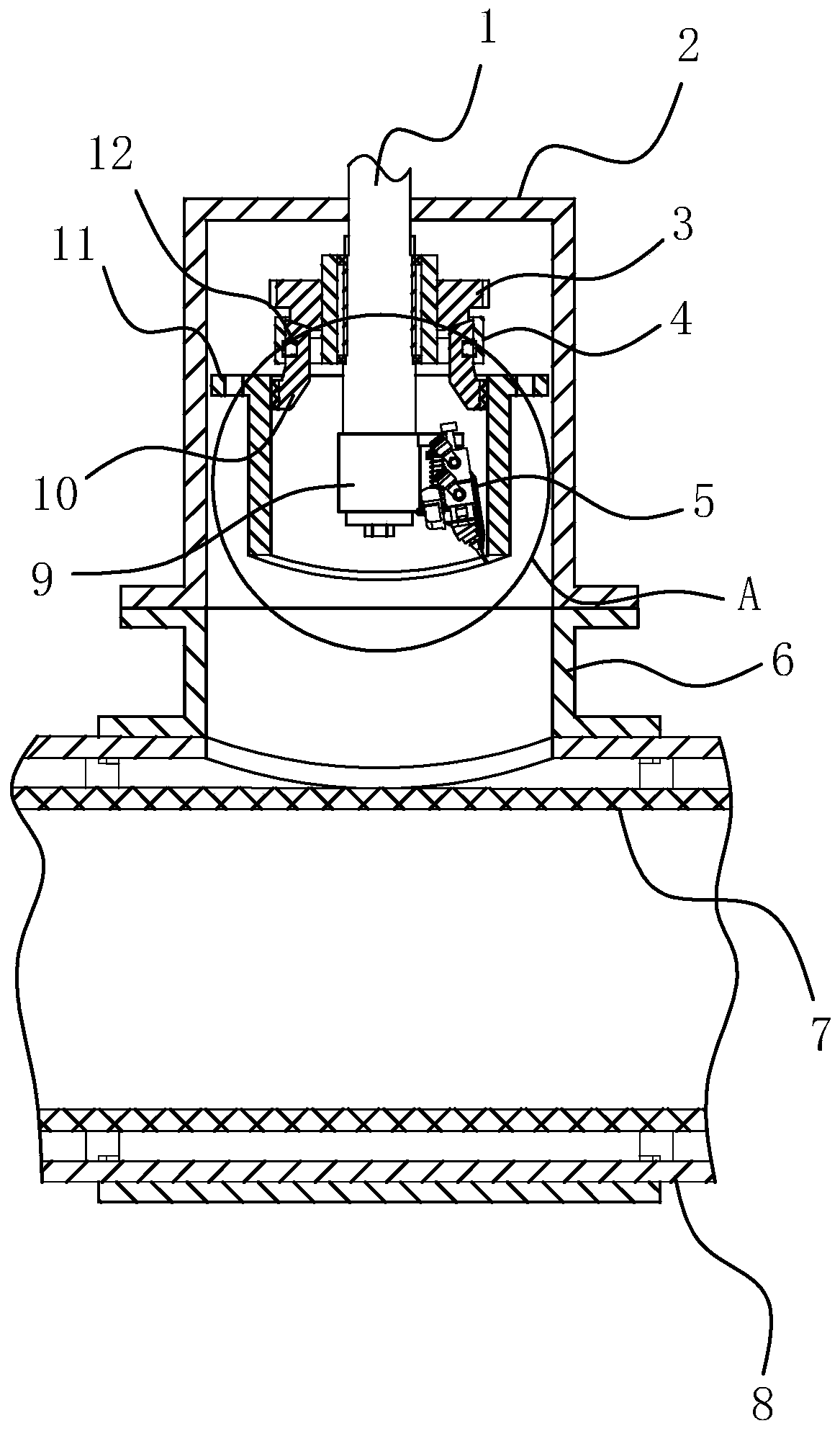

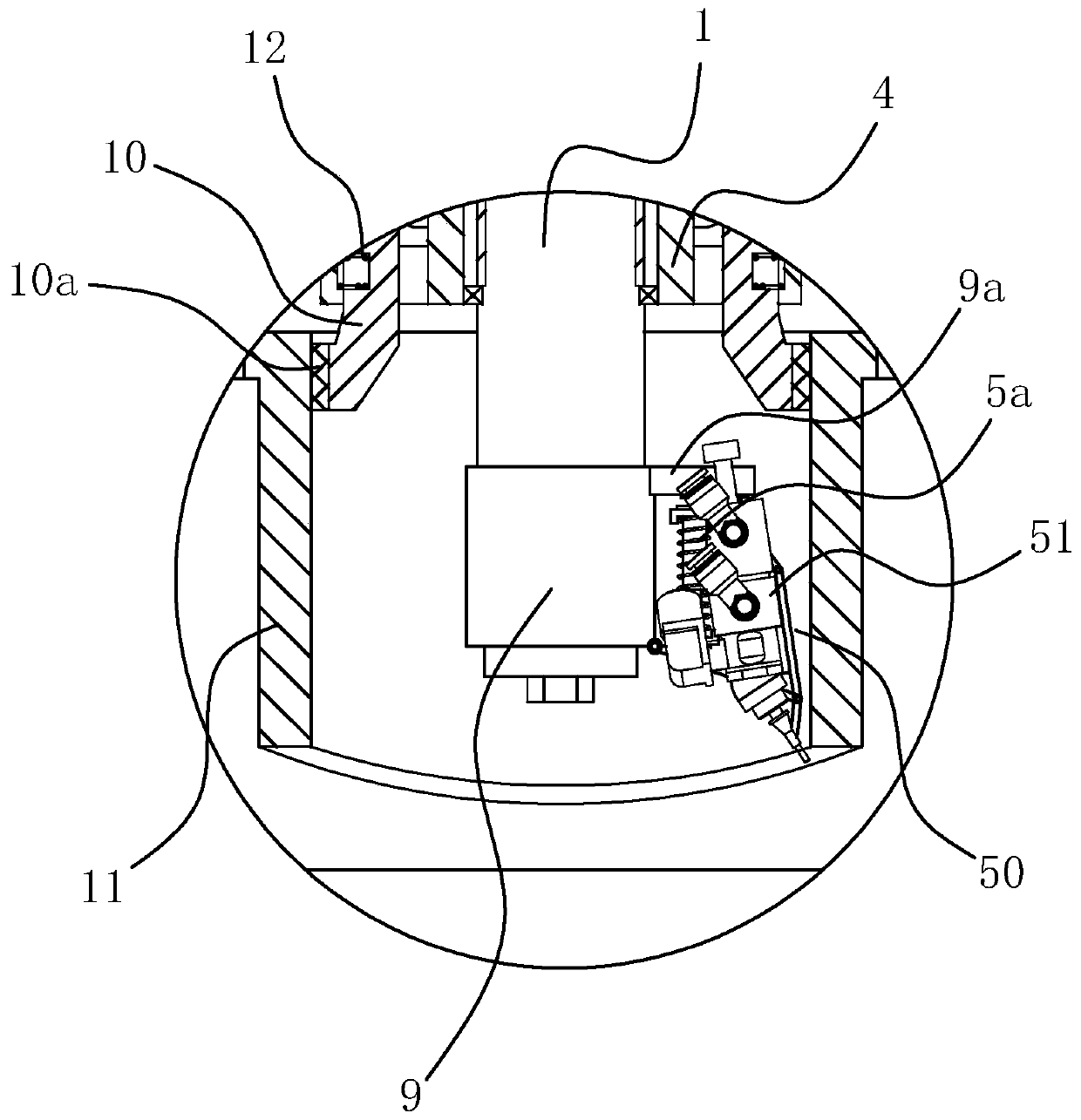

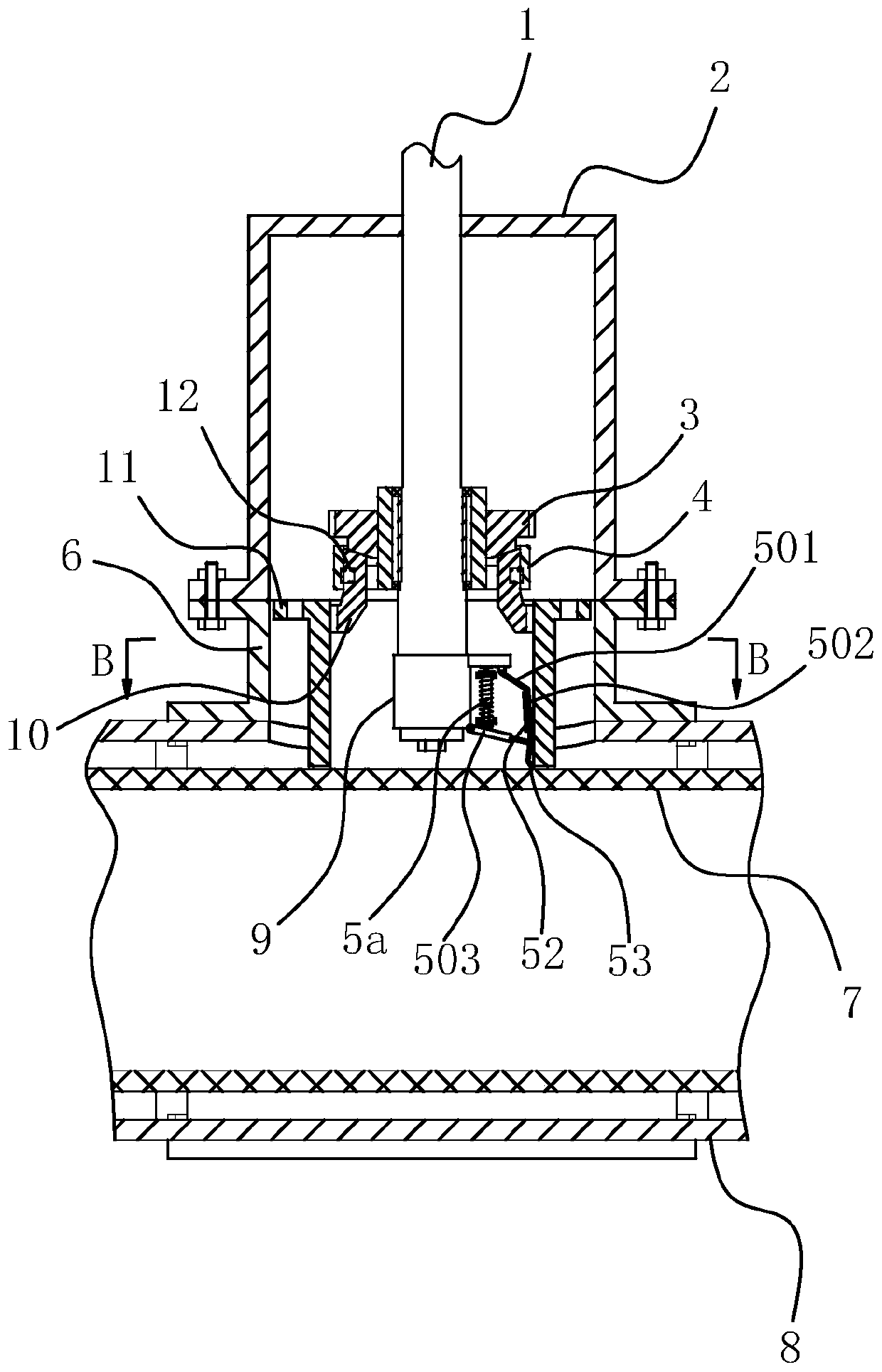

[0026] Such as figure 1 In the shown embodiment, a PE pipe fitting processing equipment includes a positioning seat 4 for positioning the inner flange 11 and a rod body 1 axially rotatable with the positioning seat 4, and an outer shell is arranged outside the positioning seat 4 2. The double-layer pipe is provided with an outer flange 6 on the perforated outer pipe 8, and the outer shell 2 is fixedly connected with the outer flange 6. The center of the top of the outer casing 2 is provided with a through hole for the rod body 1 to pass through, and the rod body 1 and the outer casing 2 are in a sliding fit. The positioning seat 4 is rotatably arranged on the rod body 1 , and the rod body 1 penetrates the positioning seat 4 and drives the positioning seat 4 together with the inner flange 11 to move radially along the inner layer tube 7 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com