A rotary treatment device for organic waste gas

A treatment device and organic waste gas technology, applied in the direction of gas treatment, separation methods, combustion types, etc., can solve the problems of reduced surface activity, large energy consumption, high cost, etc., to increase the speed of preheating, improve catalyst activity, and prolong use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiment shown in accompanying drawing:

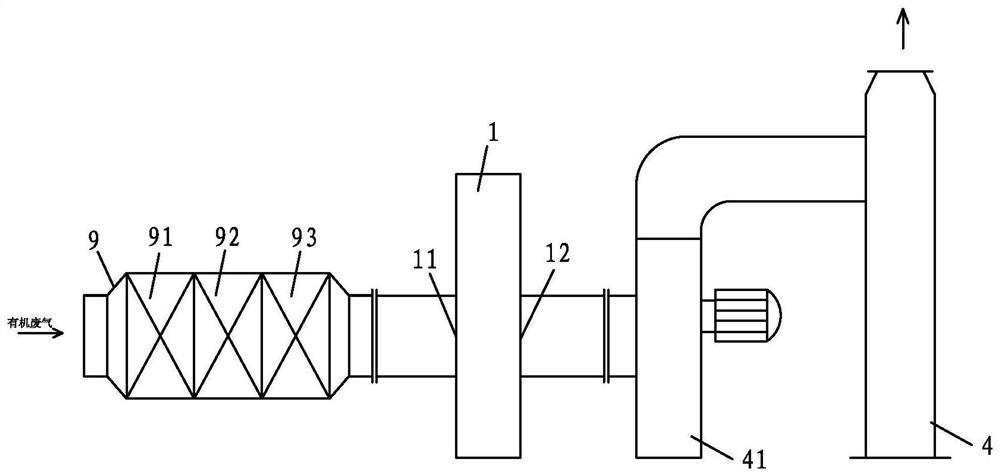

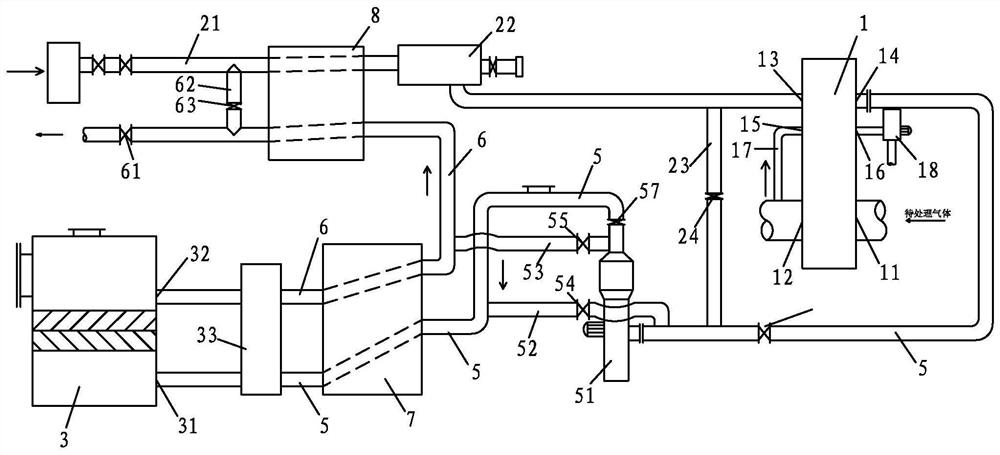

[0024] See attached Figure 1-2 As shown, an organic waste gas treatment device includes a zeolite concentration wheel 1 for absorbing waste gas (other types of concentration wheels can also be used in other embodiments), a de-additional heat component 2, and a zeolite concentration wheel 1 for desorption The regenerative catalytic combustion furnace 3 and the exhaust chimney 4 of the waste gas, the zeolite enrichment runner 1 includes a casing, a rotating wheel arranged in the casing, a driving device for driving the turning wheel, and an exhaust gas inlet 11 arranged on the casing , clean gas outlet 12, desorption inlet 13, desorption outlet 14, cooling inlet 15, cooling outlet 16, the regenerative catalytic combustion furnace 3 includes a furnace body and a catalytic inlet 31 and a catalytic outlet 32 arranged on the furnace body. Wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com