Automatic ascending and descending oyster rack culture system for resisting typhoon disaster risks

An automatic lifting and breeding system technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of easy falling apart, broken brackets, accumulation, etc., to achieve the effect of preventing marine pollution and improving risk capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

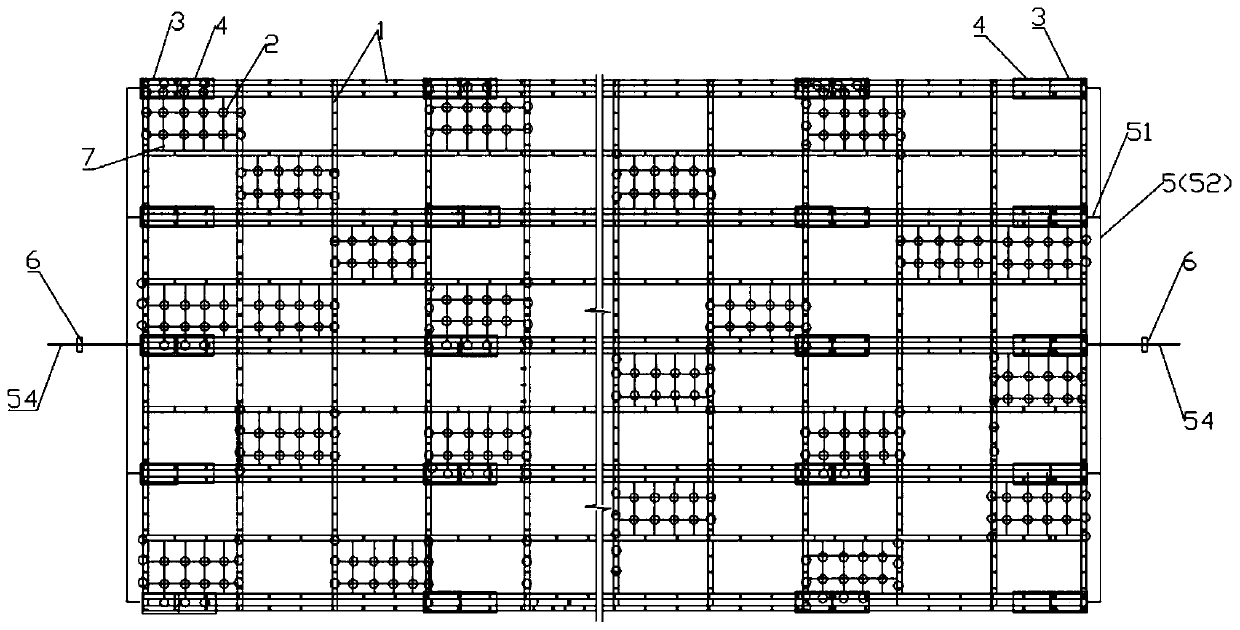

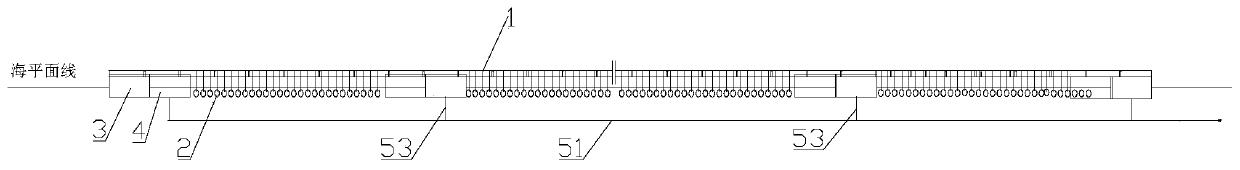

[0024] like figure 1 and figure 2 As shown, an automatic lifting oyster row culture system for combating the risk of typhoon disasters includes an oyster row main body 1, and an oyster cake 2 for mounting oyster seedlings is provided on the oyster row main body 1, and the bottom of the oyster row main body 1 A plurality of support blocks 3 for supporting the main body 1 of the oyster steak are arranged at intervals, and the support blocks 3 in this embodiment are fixedly bound to the bottom of the main body 1 of the oyster steak by ropes. The bottom of the main body 1 of the oyster row is also provided with a plurality of hollow lifting buoys 4, and the plurality of lifting buoys 4 are connected by connecting pipes 5, and a switch 6 is arranged on the connecting pipes 5. figure 1 In , for the sake of neatness in the picture, only a part of the oyster cake 2, the support block 3 and the lifting buoy 4 are drawn. The end of the connecting pipe 5 far away from the lifting buoy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com