Thermally conductive sheet precursor, thermally conductive sheet obtained from precursor and production method thereof

A technology of thermal conductive sheet and precursor, applied in semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as performance degradation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

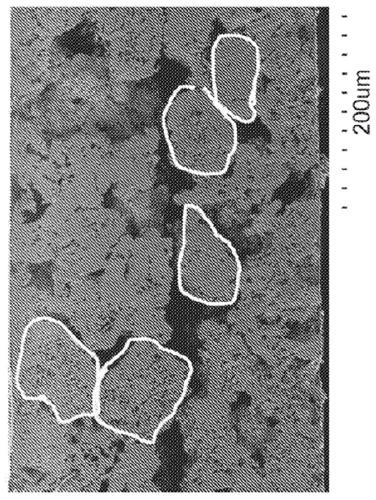

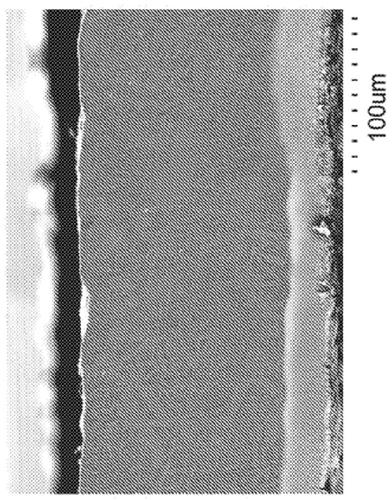

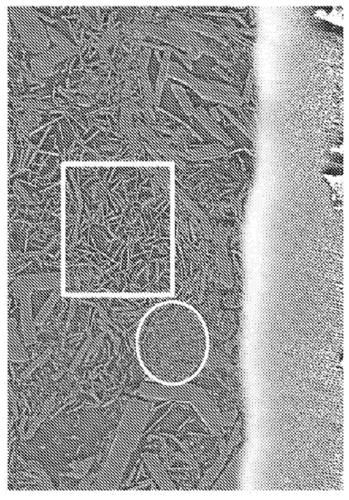

Image

Examples

Embodiment 1 to 9 and comparative example 1 to 5

[0084] Although specific embodiments of the present disclosure will be illustrated in the following examples, the present disclosure is not limited to these examples.

[0085] The products etc. used in these Examples are shown in Table 1 below.

[0086] [Table 1]

[0087]

[0088]

[0089] The materials shown in Table 1 were mixed according to the ratio shown in Table 2 to make a corresponding coating solution for making the thermal conductive sheet precursor. Here, all numerical values in Table 2 refer to parts by mass.

[0090]

[0091]

[0092] assessment test

[0093] The characteristics and internal structure of the heat transfer sheet were evaluated using the following methods.

[0094] Thermal conductivity test

[0095] The thermal diffusivity was measured as follows using the flash analysis method of Hyperflash (trade name) LFA467 manufactured by Netzsch. Place the thermal conductive sheet precursor between two release films, and put it into a ...

Embodiment 1

[0102]Immediately after preparing a coating solution TA-3 containing A100 and P003 (85 / 15 in ratio) for the thermal conductive sheet precursor, a layer of 38 μm thick PET release film was applied using a knife coater with a gap interval of 290 μm (A31: available from Du Pont-Toray Co., Ltd.), followed by drying at 65° C. for 5 minutes. The samples were further dried at 100° C. for 5 minutes to make each thermal conductive sheet precursor with a thickness of about 180 μm to apply various levels of pressure. Next, for each thermal conductive sheet precursor, two thermal conductive sheet precursors were laminated, respectively applying pressures of 1 MPa, 2 MPa, 3 MPa, and 10 MPa at 65° C. for 5 minutes to produce thermal conductive sheets. The results concerning the relative thickness of the thermal pad obtained, i.e. the ratio between the thermal pad thickness and the thickness of the thermal pad precursor and the dielectric breakdown voltage as Figure 4 shown. Here, an embo...

Embodiment 2

[0104] Thermal pads were fabricated in the same manner as in Example 1, except that instead of TA, the coating solution TA-5 containing A100 and P003 (60 / 40 ratio) for the thermal pad precursor was used here -3. The results about the relative thickness of the heat conducting sheet and the dielectric breakdown voltage are as follows: Figure 4 shown. Embodiments to which pressures of 1 MPa and 2 MPa were applied were also used here as reference examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com