3d NAND memory and its formation method

A 3D NAND and memory technology, which is applied in semiconductor devices, electrical solid devices, electrical components, etc., can solve problems such as storage structure breakage and storage structure failure, and achieve the effect of reducing difficulty and simplifying process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

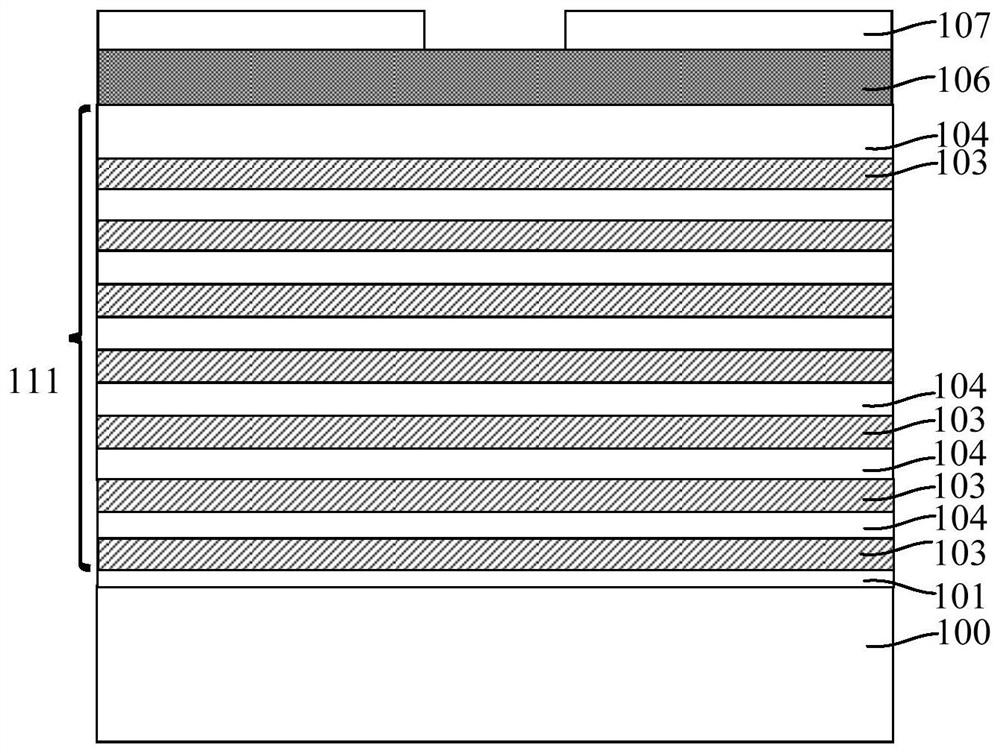

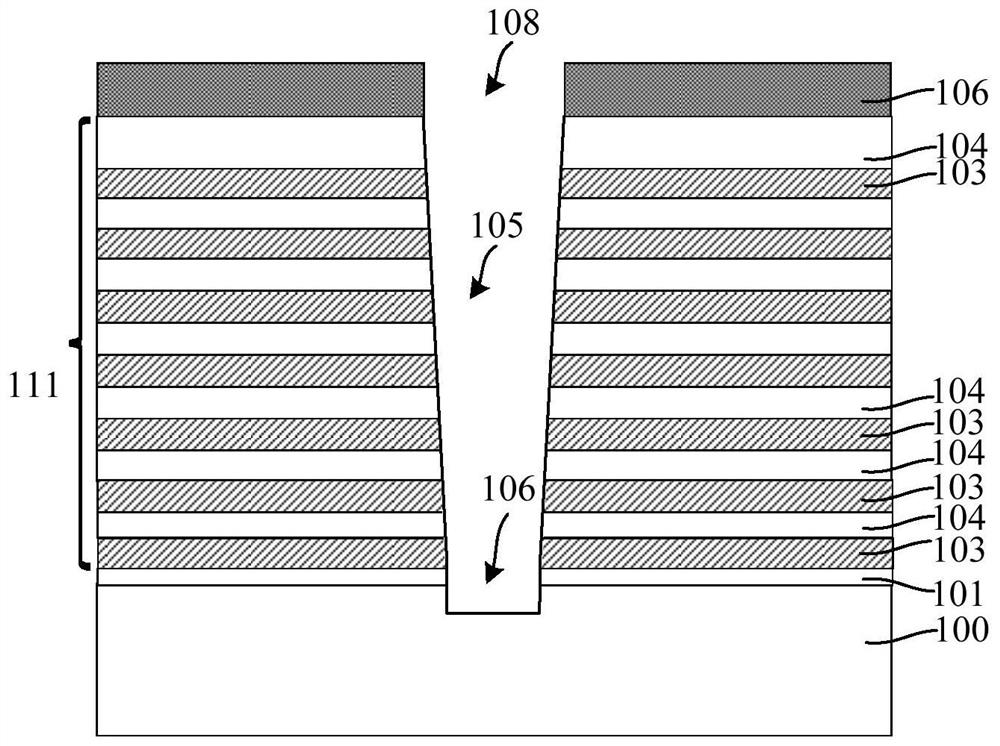

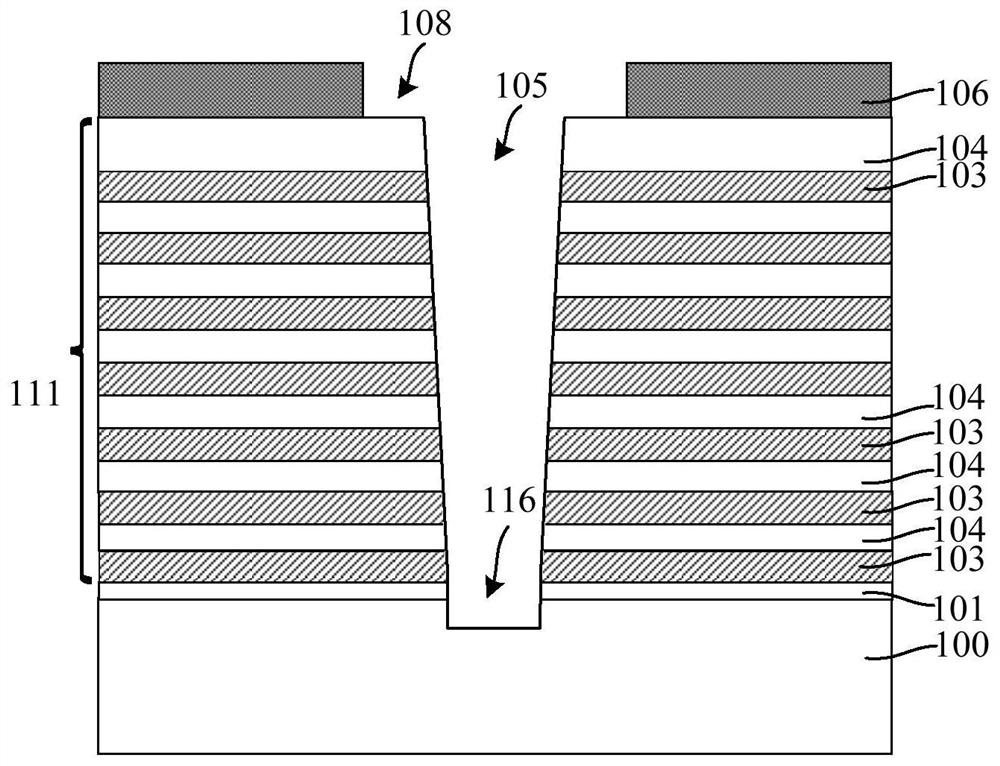

[0033] As mentioned in the background, the existing 3D NAND memory with a multilayer stack structure has the problem that the position of the channel hole formed in the upper layer stack structure and the channel hole formed in the lower layer stack structure are offset. When the upper and lower channel holes are formed When the position is shifted, the difficulty of the storage structure formed in the channel hole will increase, and the storage structure formed in the channel hole will easily produce defects such as fractures (when the position of the upper and lower channel holes is offset, the upper channel hole The bottom part is located on the surface of the stacked structure below, and laterally extending steps are formed on the side walls of the channel holes connected up and down. The existence of the steps makes it easy for the charge storage layer in the storage structure to be cut off at the steps when the storage structure is formed. ), making the storage structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com