Pipeline barrier clearance patrol device

A technology for clearing obstacles and pipelines, which is applied in the field of pipeline obstacle-clearing inspection devices, can solve the problems of extended construction period, increased obstacle-clearing time, and increased conveyor power, so as to shorten the time of obstacle-clearing, improve the efficiency of obstacle-clearing, and improve The effect of movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

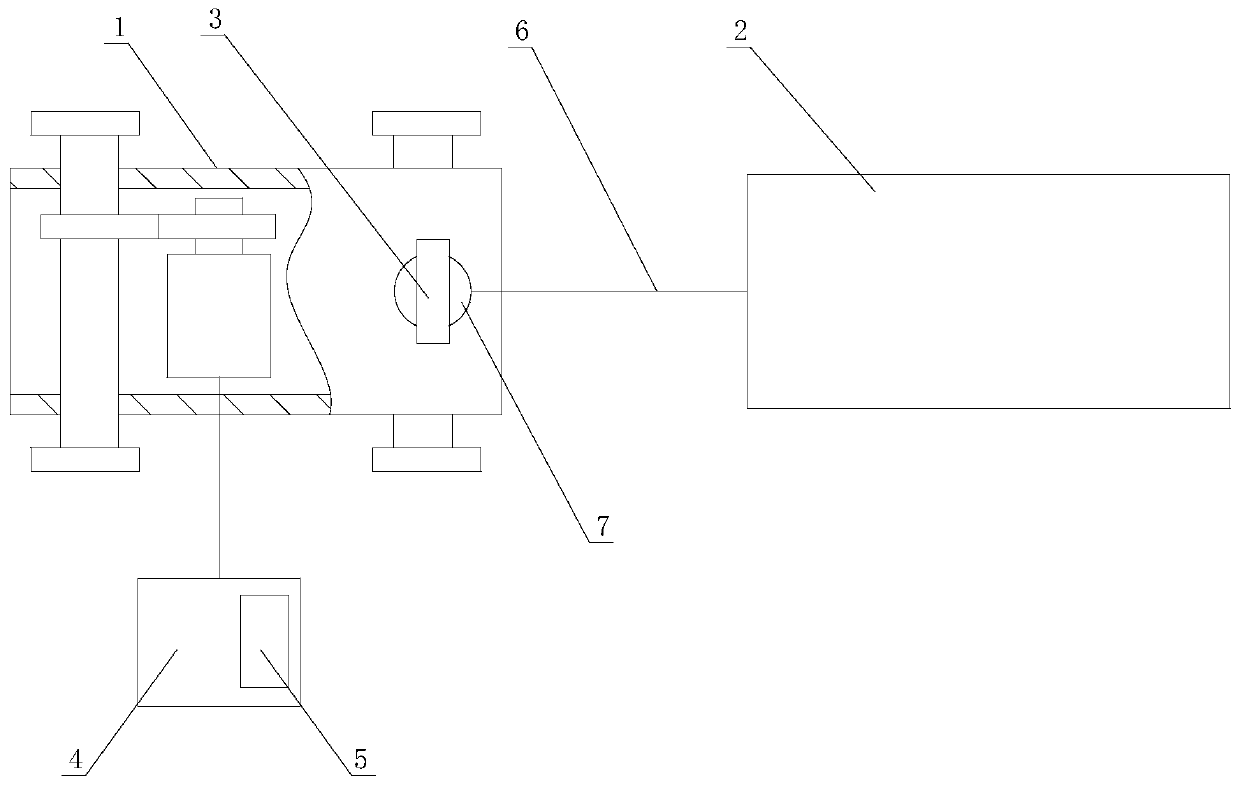

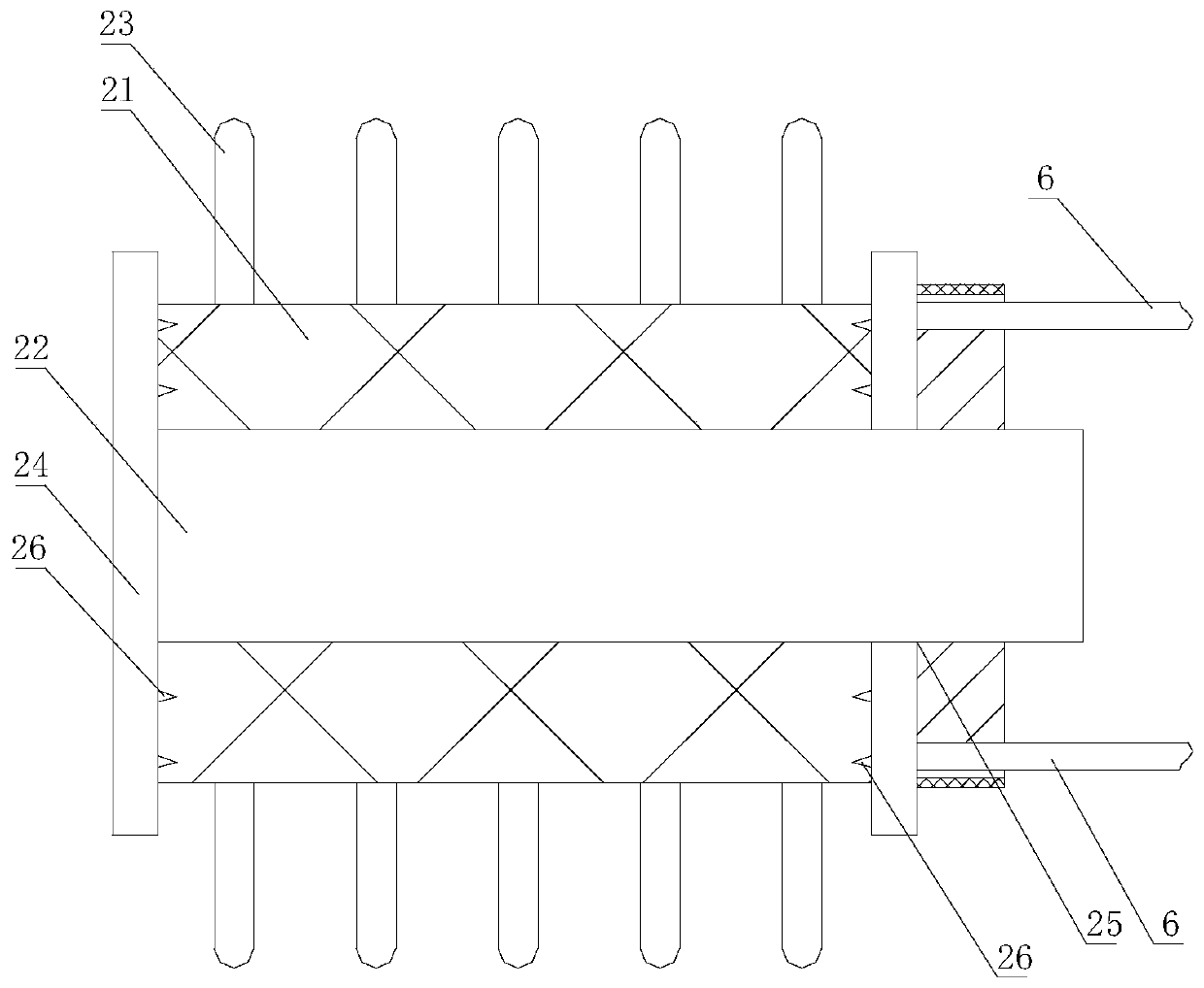

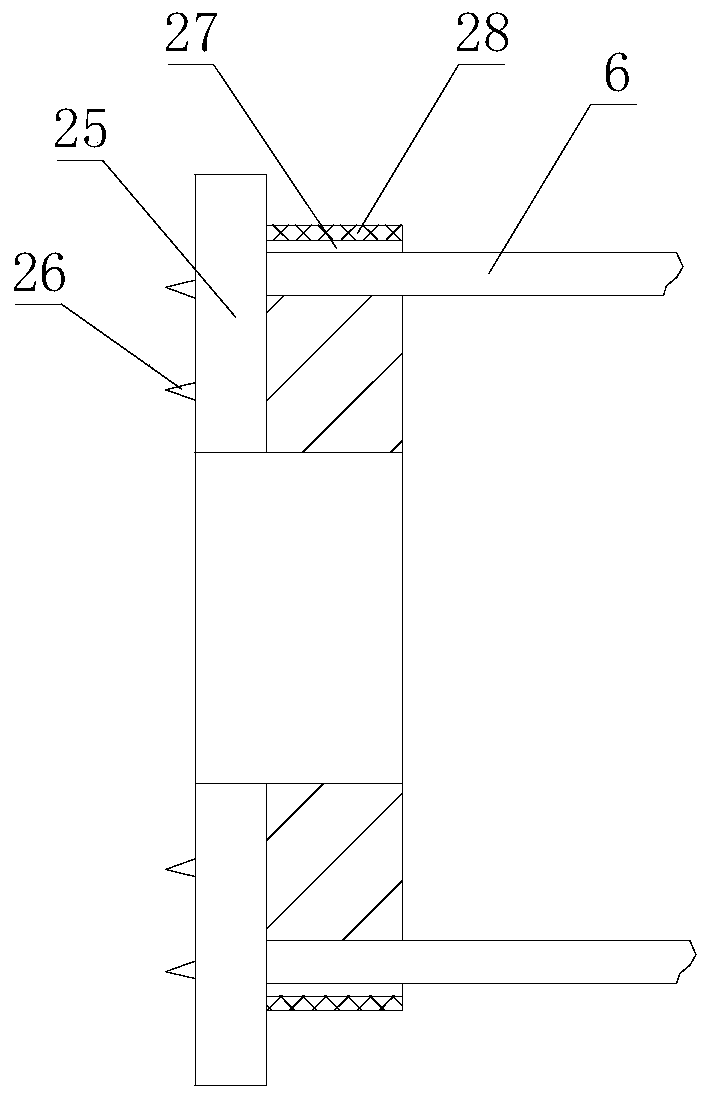

[0024] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, a pipeline obstacle removal inspection device includes a walking assembly 1 and an obstacle removal assembly 2. The obstacle removal assembly 2 includes a polyurethane sleeve 21, and the polyurethane sleeve 21 is detachably mounted on the walking On the assembly 1, the walking assembly 1 is also provided with a camera assembly 3, and the walking assembly 1 is also connected with a control assembly 4 that controls the movement of the walking assembly 1, and the control assembly 4 is provided with a camera assembly 3 that links to each other. Show component 5.

[0025] The camera assembly 3 on the walking assembly 1 carries out imaging processing to the pipeline, so the pipeline can be imaged during the walking assembly 1 walking process, and receives the image information captured by the imaging assembly 3 in real time through the display assembly 5. Next, the walking process In the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com