Ionic polyurethane hot melt adhesive foam product and preparation method thereof

A polyurethane hot melt adhesive and ionic technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as uneven foam, achieve uniform mixing, uniform structure, and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

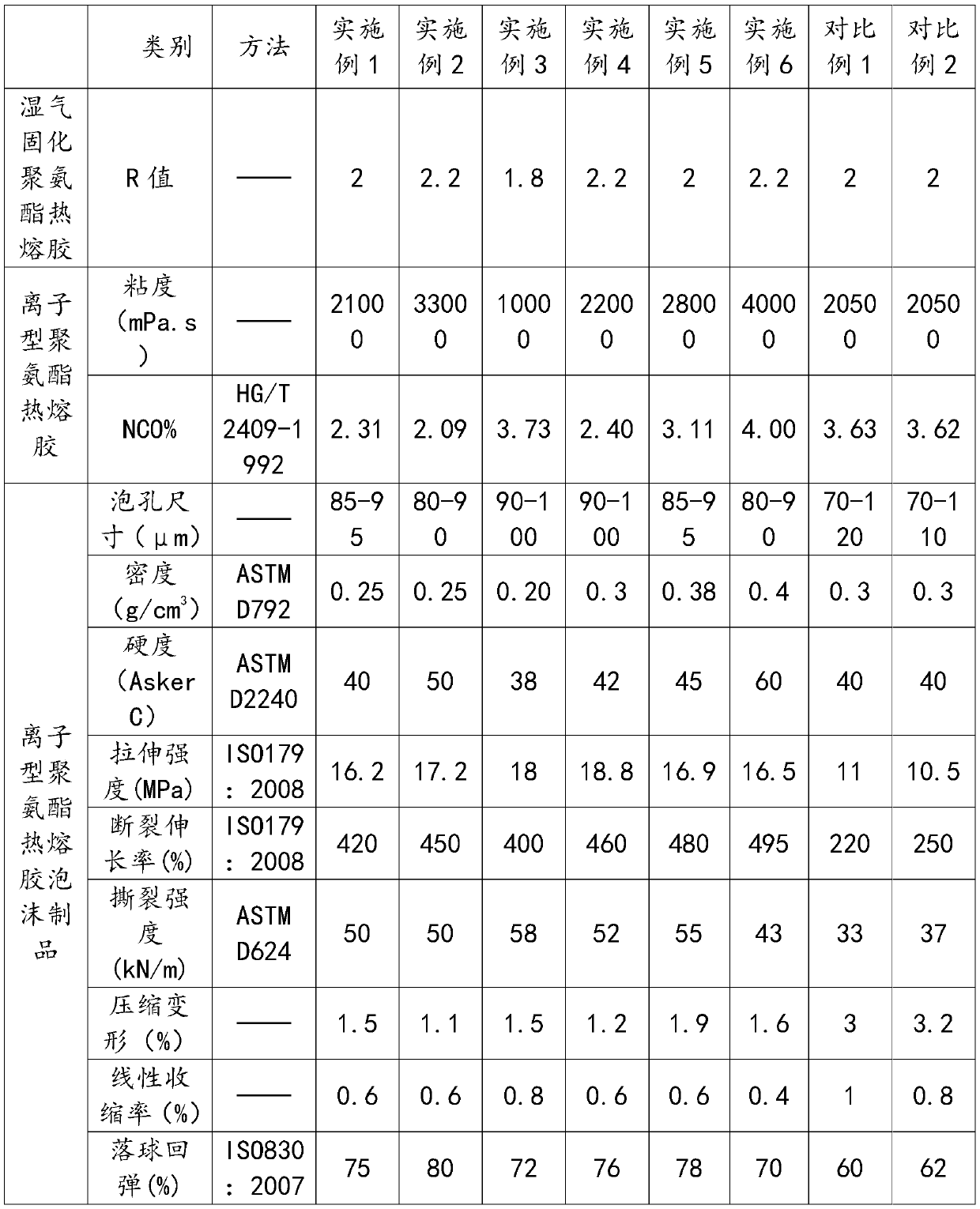

Examples

Embodiment 1

[0038] A kind of preparation method of ionic polyurethane hot-melt adhesive foam product, comprises the following steps:

[0039] 1. Preparation of moisture-cured polyurethane hot melt adhesive

[0040] S1, 100g of polytetrahydrofuran polyether polyol with a molecular weight of 1800mol / L and a functionality of 2, 0.03g of phosphoric acid, 0.3g of antioxidant Irganox1010 (purchased from BASF), 0.3g of light stabilizer Tinuvin 770 (purchased from BASF), 0.5g of anti-ultraviolet additive Tinuvin327 (purchased from BASF) and 0.5g antifungal agent AM110 (purchased from Huntsman) were added to the reactor and melted at 120°C Mix and stir while vacuumizing and dehydrating for 2 hours under the condition of vacuum degree of -0.09MPa to obtain the mixed material;

[0041] S2. Cool the mixed material in step S1 to 60°C, then add 27.8g of diphenylmethane-4,4'-diisocyanate (MDI) and stir, react at 60°C under normal pressure for 15min, then raise the temperature To 110°C, vacuum negative...

Embodiment 2

[0048] A kind of preparation method of ionic polyurethane hot-melt adhesive foam product, comprises the following steps:

[0049] 1. Preparation of moisture-cured polyurethane hot melt adhesive

[0050] S1, 60g of polytetrahydrofuran polyol with a molecular weight of 2000mol / L and a functionality of 2, 40g of polybutylene adipate with a molecular weight of 2000mol / L and a functionality of 2, 0.03g of phosphoric acid, and 0.3g of Antioxidant Irganox1010 (purchased from BASF company), 0.3g light stabilizer Tinuvin 770 (purchased from BASF company), 0.5g UV-resistant auxiliary agent Tinuvin327 (purchased from BASF company) and 0.5g antifungal agent AM110 (purchased from BASF company) (purchased from Huntsman Company) was added into the reaction kettle, melted, mixed and stirred at 120°C and simultaneously vacuumed and dehydrated for 2 hours under the condition of vacuum degree of -0.09MPa to obtain the mixed material;

[0051] S2. Cool the mixed material in step S1 to 60°C, then...

Embodiment 3

[0058] A kind of preparation method of ionic polyurethane hot-melt adhesive foam product, comprises the following steps:

[0059] 1. Preparation of moisture-cured polyurethane hot melt adhesive

[0060] S1, the molecular weight of 100g is 1000mol / L, the polytetrahydrofuran polyol of 2 functionalities, 0.03g phosphoric acid, the antioxidant Irganox1010 of 0.3g (purchased from BASF company), the light stabilizer Tinuvin 770 of 0.3g ( (purchased from BASF Company), 0.5g of anti-ultraviolet additive Tinuvin327 (purchased from BASF Company) and 0.5g antifungal agent AM110 (purchased from Huntsman Co.) were added to the reactor, melted and mixed at 120°C and stirred At the same time, the mixed material was obtained after vacuum dehydration for 2 hours under the condition of vacuum degree of -0.09MPa;

[0061] S2. Cool the mixed material in step S1 to 60°C, then add 45g of diphenylmethane-4,4'-diisocyanate (MDI) and stir, react at 60°C under normal pressure for 15min, then raise the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com