Negative oxygen ion inorganic coating and preparation method thereof

A technology of negative oxygen ions and inorganic coatings, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve the problems of excessive radioactivity and failure to meet the standards of inorganic coatings, and achieve the effect of low radioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

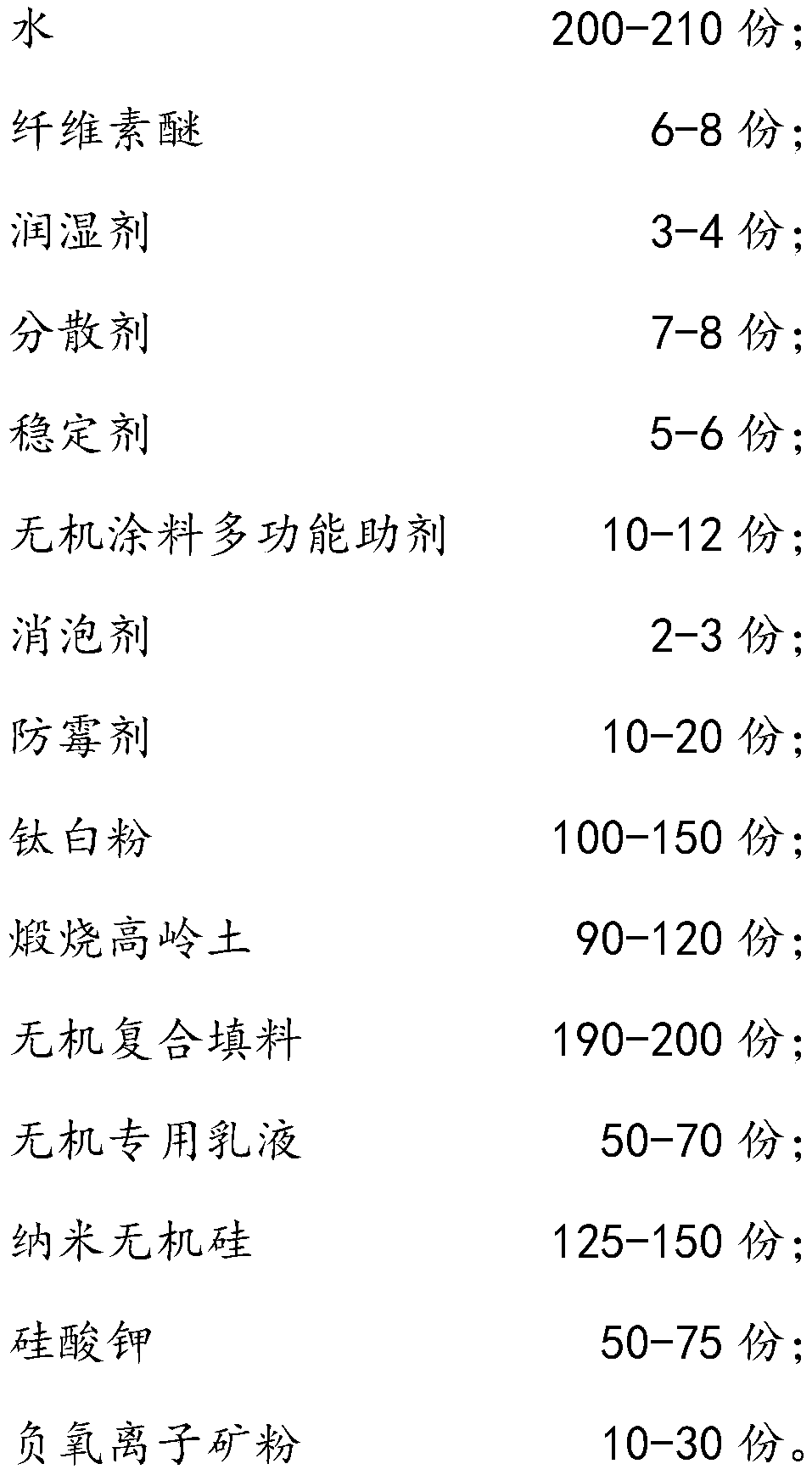

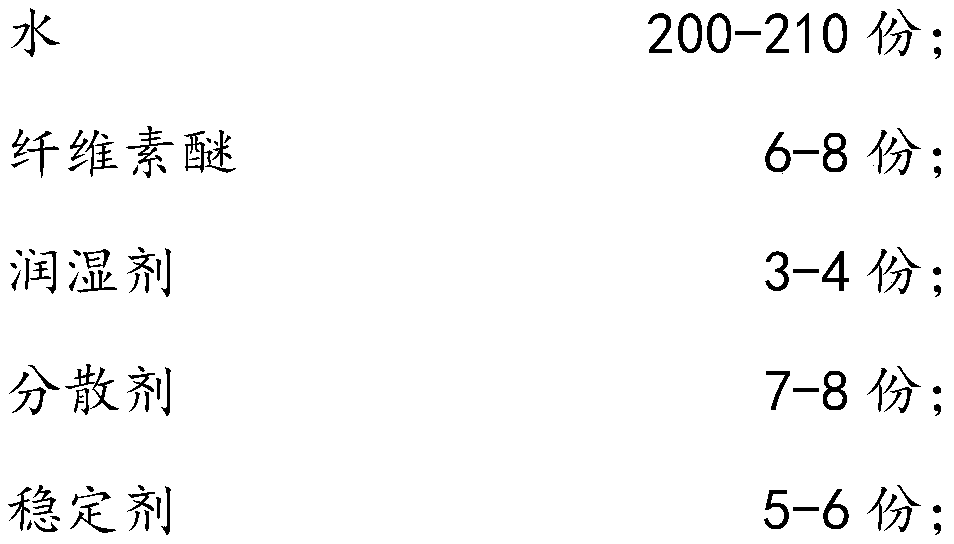

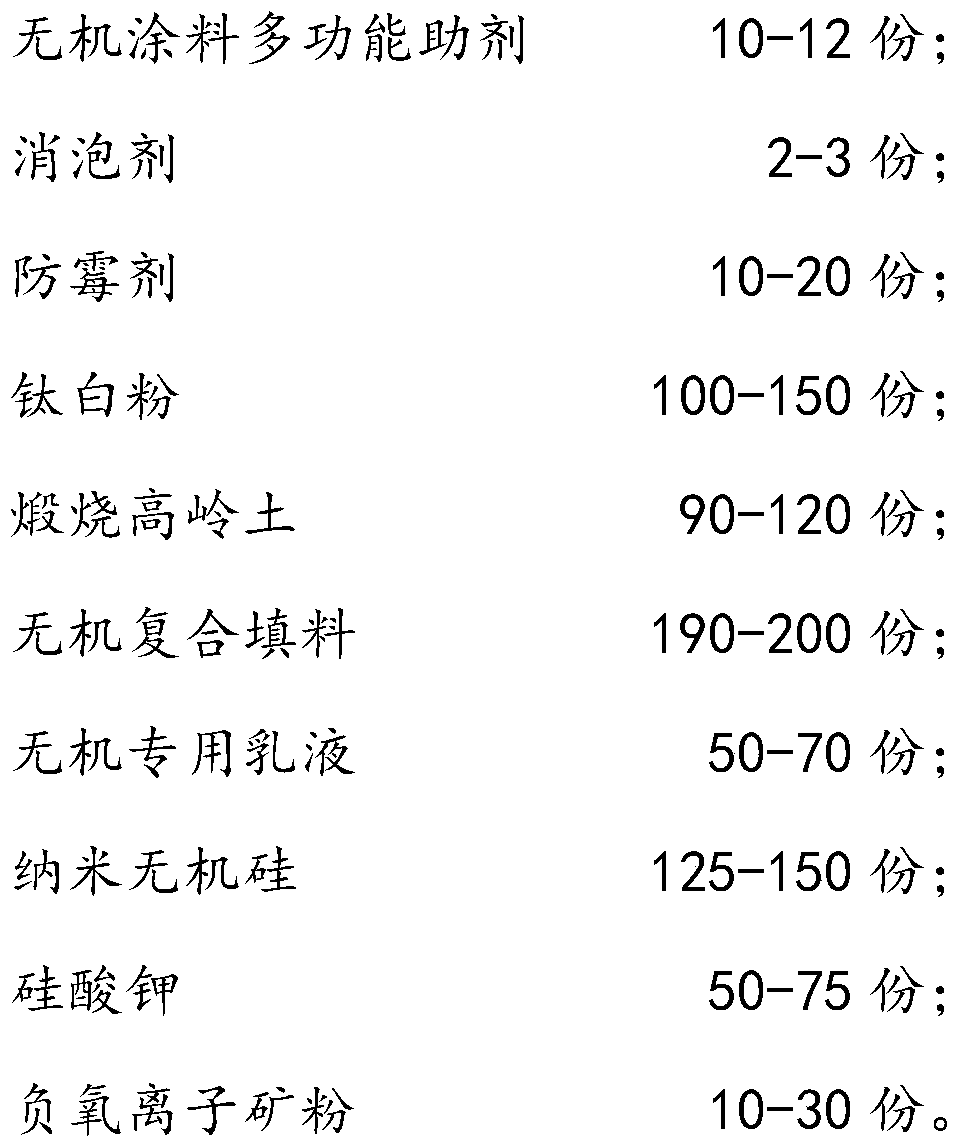

Method used

Image

Examples

Embodiment 1

[0055] Step 1. In the stirring state, mix 100 parts of deionized water and 10 parts of negative oxygen ion mineral powder I, and continue to stir until uniform to obtain a negative oxygen ion mixture. The mixer speed is 500r / min, and the stirring time is 10min;

[0056] Step 2. Add a paint stabilizer (acid-base adjustment reagent) to the negative oxygen ion mixture in step 1, adjust the pH value to 7.5, and continue stirring to obtain a stable negative oxygen ion mixture. The mixer speed is 500r / min, stirring Time 10min;

[0057] Step 3. In the state of stirring, add 3 parts of cellulose ether, 7 parts of dispersant, 3 parts of wetting agent, and 5 parts of stabilizer to the negative oxygen ion mixture in step 2, stir evenly to obtain a dispersion, and the speed of the mixer is 500r / min, stirring time 10min;

[0058] Step 4. In the stirring state, add 100 parts of titanium dioxide, 90 parts of calcined kaolin, 190 parts of inorganic composite filler, 3 parts of cellulose eth...

Embodiment 2

[0062] Step 1. In the stirring state, mix 100 parts of deionized water and 10 parts of negative oxygen ion mineral powder I, and continue to stir until uniform to obtain a negative oxygen ion mixture. The mixer speed is 500r / min, and the stirring time is 10min;

[0063] Step 2. Add a paint stabilizer (acid-base adjustment reagent) to the negative oxygen ion mixture in step 1, adjust the pH value to 8.5, and continue stirring to obtain a stable negative oxygen ion mixture. The mixer speed is 500r / min, stirring Time 10min;

[0064] Step 3. In the state of stirring, add 3 parts of cellulose ether, 7 parts of dispersant, 3 parts of wetting agent, and 5 parts of stabilizer to the negative oxygen ion mixture in step 2, stir evenly to obtain a dispersion, and the speed of the mixer is 500r / min, stirring time 10min;

[0065] Step 4. In the stirring state, add 100 parts of titanium dioxide, 90 parts of calcined kaolin, 190 parts of inorganic composite filler, 3 parts of cellulose eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com