Vision-based multi-industrial-robot fault detection method and system

An industrial robot, fault detection technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of high cost and complex detection process, and achieve the effect of low cost and simple and accurate detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

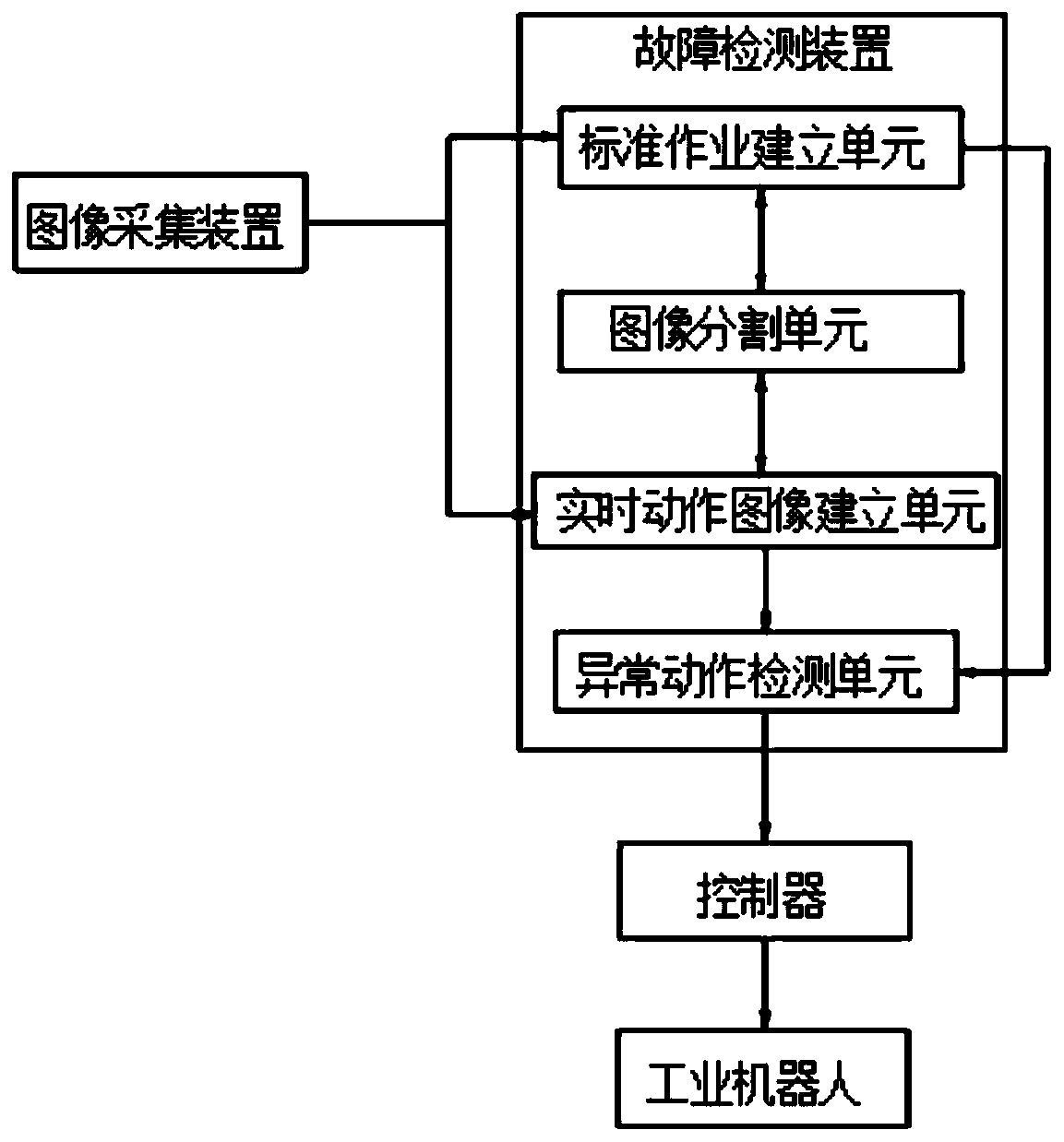

[0072] refer to figure 1 , a vision-based multi-industrial robot fault detection system, including an image acquisition device, a fault detection device and a controller.

[0073] Each part will be described in detail below in turn.

[0074] The image acquisition device is used to collect standard operation videos of multi-industrial robots, and is also used to collect real-time action videos of multi-industrial robots in real time. It is worth noting that, in this embodiment, the image acquisition device is a high-definition camera.

[0075] The fault detection device is used to receive the multi-industrial robot standard operation video collected by the image acquisition device and establish a plurality of single-industrial robot standard operation mode video frame sequences A13, 11 , I 12 ,…I 1m >, also be used for receiving the multi-industrial robot real-time action video that image acquisition device collects in real time, set up a plurality of single industrial robot...

Embodiment 2

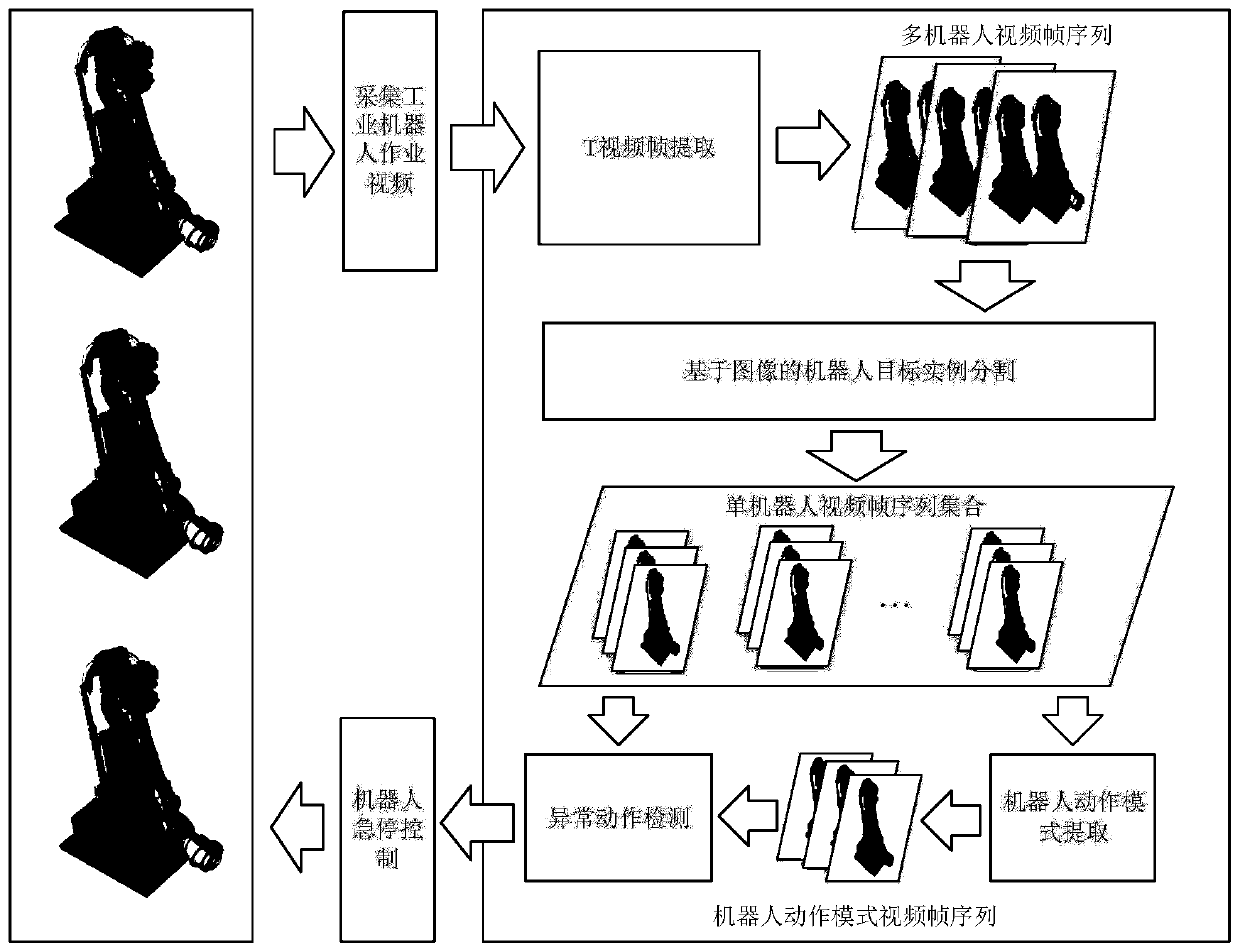

[0114] refer to figure 2 , 6 , a vision-based multi-industrial robot fault detection method, including the following steps,

[0115] S1: collect the standard operation video of multiple industrial robots, establish the video frame sequence A13 of multiple single industrial robot standard operation modes, , execute S2;

[0116] S2: Collect multi-industrial robot operation videos in real time, and create multiple single-industrial robot real-time operation video frame sequences A22, . The single-industrial robot real-time operation video frame sequence A22 includes multiple frames of single-industrial robot real-time Action image, execute S3;

[0117] S3: Match the real-time motion image of the single industrial robot with the image in the corresponding single industrial robot standard operating mode video frame sequence A13, and use the two-stage method to detect whether the single industrial robot is abnormal. If yes, execute S4, if not, execute S2 ;

[0118] S4: Control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com