Steel bar welding device for pipe gallery construction

A welding device and steel bar technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of the movement and shaking of the steel cage, the decrease of the strength of the steel cage, and the change of the structural strength of the steel cage, so as to improve the production efficiency and improve the stability. Sexual, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

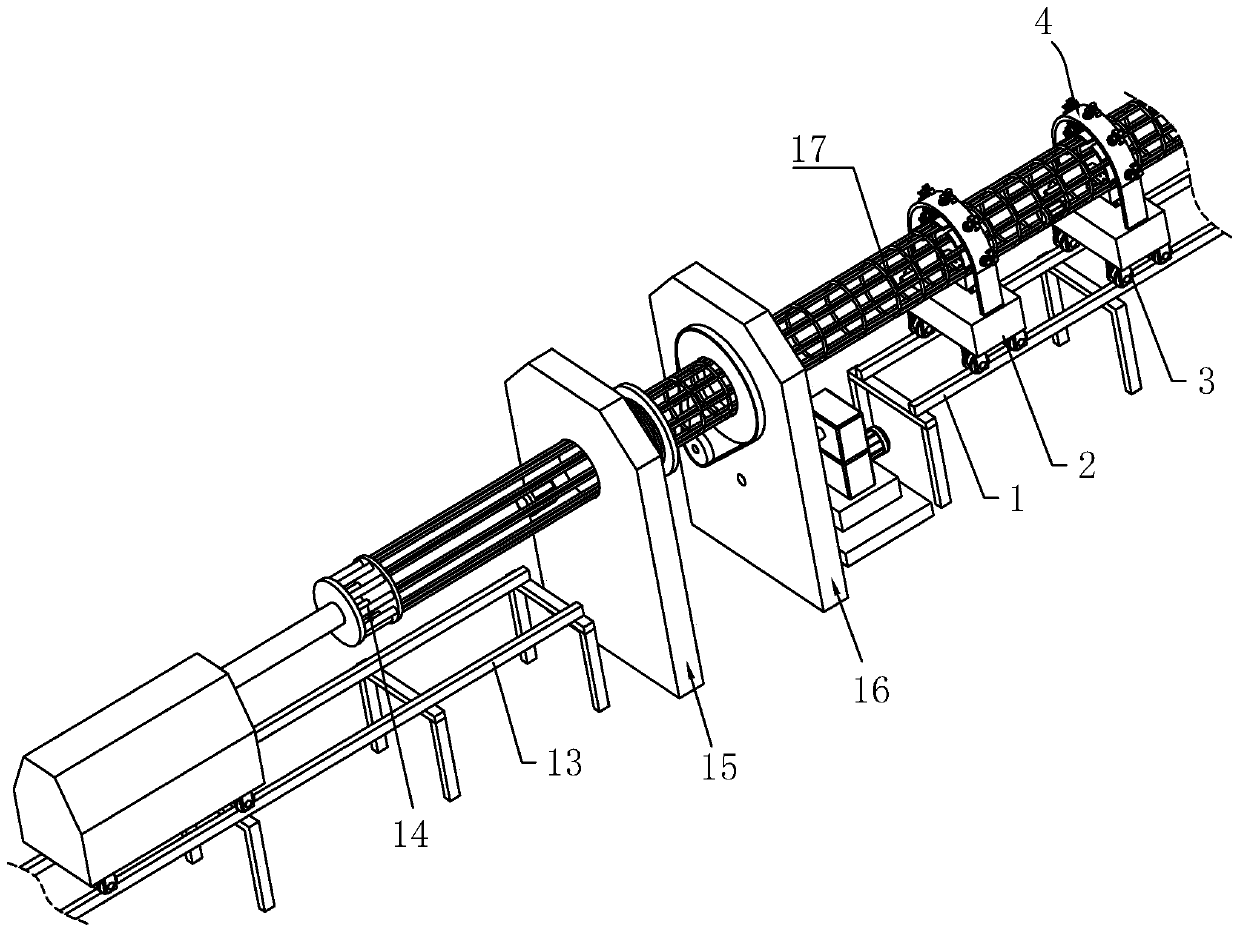

[0042] A steel bar welding device for pipe gallery construction, refer to figure 1 , which includes a track frame 13, a traction mechanism 14 is provided for sliding on the track frame 13, and one side of the traction mechanism 14 is sequentially provided with a winding mechanism 15 and a seam welding mechanism 16; the traction mechanism 14 is used to clamp and drive a plurality of steel bars Move, steel cage 17 utilizes winding mechanism 15 to wind steel wire on a plurality of steel bars during moving, then welds steel bar and steel wire by roll welding mechanism 16, and steel cage 17 can be welded and formed finally.

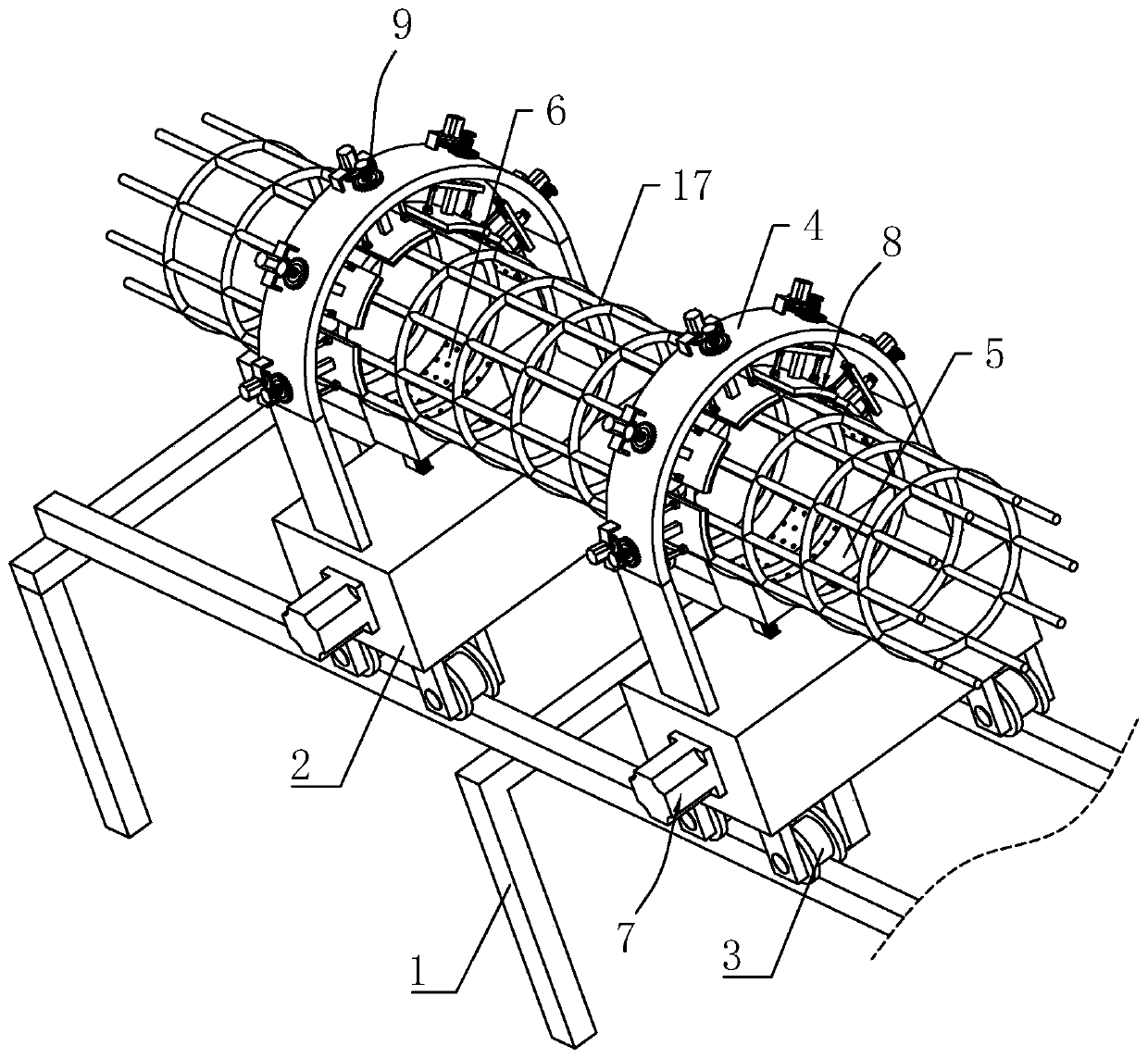

[0043] refer to figure 1 and figure 2 , the roll welding mechanism 16 is provided with a guide rail frame 1 on the side facing away from the winding mechanism 15, the length direction of the guide rail frame 1 is in the same direction as the discharge direction, and a plurality of support seats 2 are provided for the sliding frame between the two guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com