Automatic spraying device

An automatic spraying and heating device technology, applied in spraying devices, devices for coating liquid on the surface, coatings, etc., can solve the problem that the uneven spraying of the catalyst layer affects the structure and physical and chemical properties of the membrane electrode catalyst layer, and affects the membrane electrode fuel cell. Performance, cannot effectively solve the problem of membrane swelling, etc., to achieve the effect of uniform force, improve quality, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

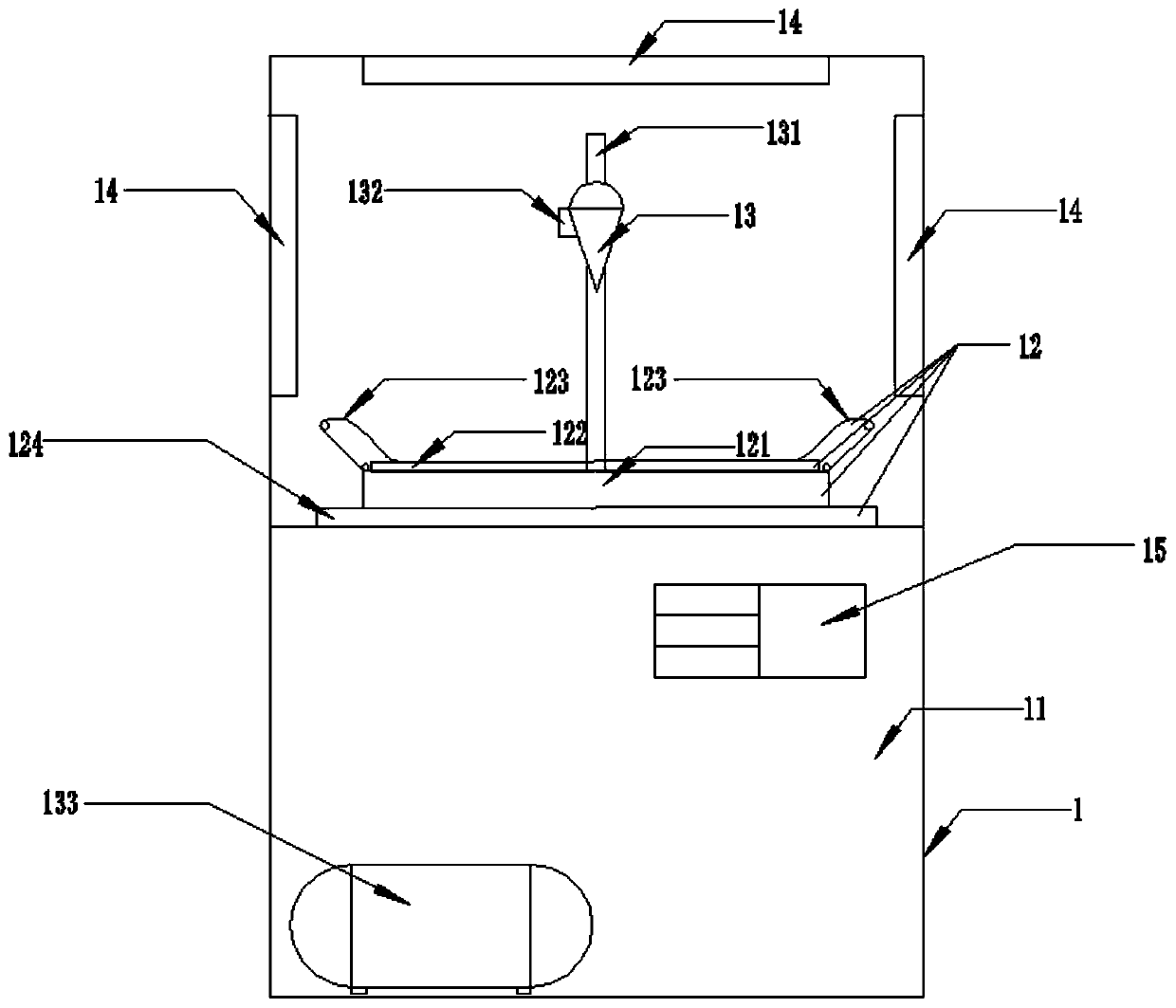

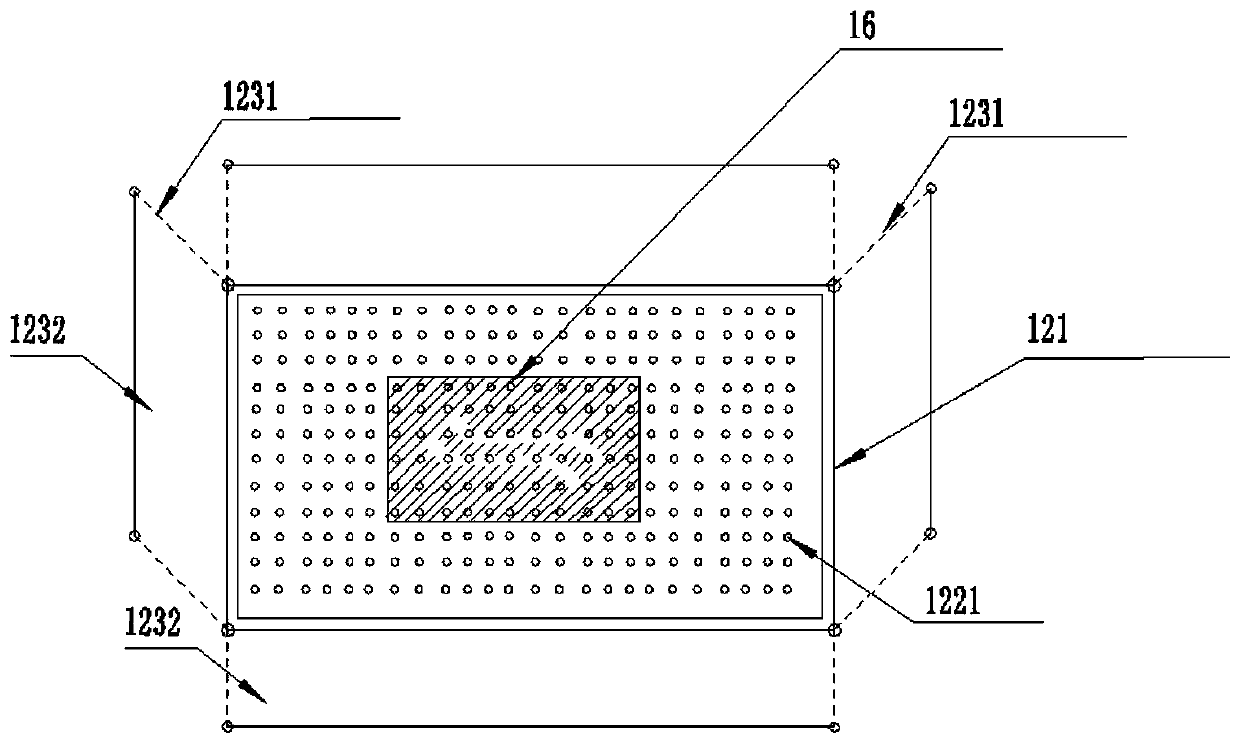

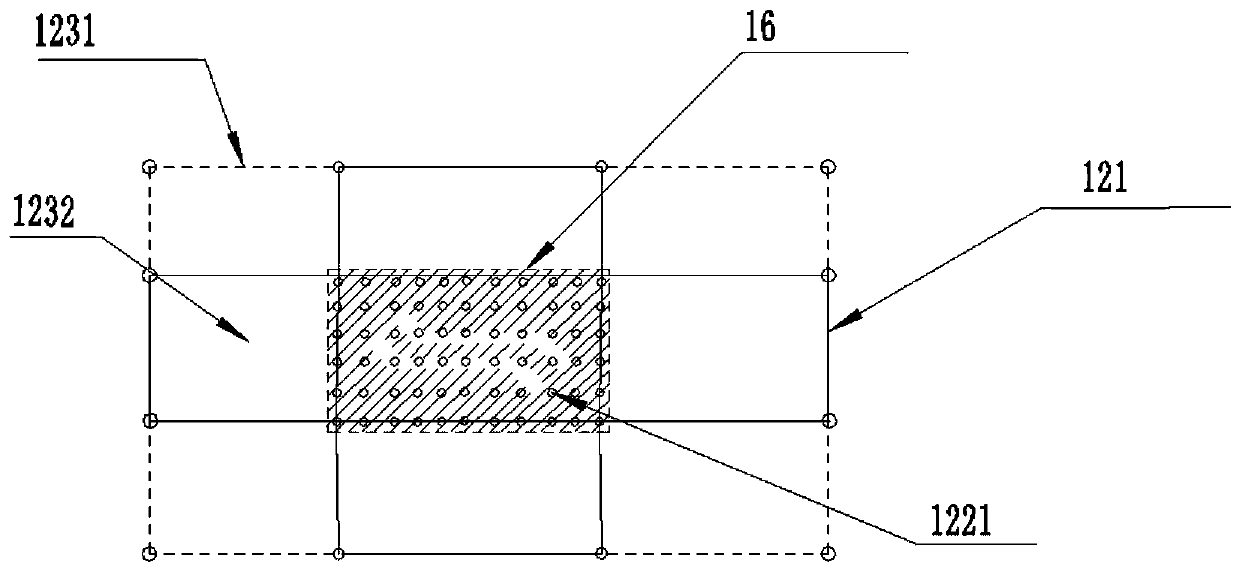

[0036] This embodiment discloses an automatic spraying device 1, which includes: a heating box 11 provided with a heating device, a spraying operation cavity is formed in the heating box 11, and when the automatic spraying device 1 is in operation, the heating device in the heating box The spraying operation cavity is heated; the spraying operation cavity is provided with a spray gun 13 and a workbench 12 for fixing the workpiece to be sprayed. When the workpiece to be sprayed is fixed on the workbench 12, the spray gun 13 sprays the spray material to the workpiece to be sprayed superior.

[0037] Further, the workpiece to be sprayed is a proton exchange membrane, and the sprayed material is a catalyst slurry.

[0038] Further, the heating device includes an infrared heating device 14, and when the automatic spraying device is working, the infrared heating device 14 keeps the temperature in the spraying cavity within a preset temperature range. Infrared heating device 14 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com