Water supply decontamination system for tower crane spraying machine

A technology of tower crane spraying machine and water wheel, which is applied in the field of spraying machines, can solve the problems of reducing dust suppression effect, nozzle blockage, environmental pollution, etc., and achieve the effect of avoiding mesh blockage and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

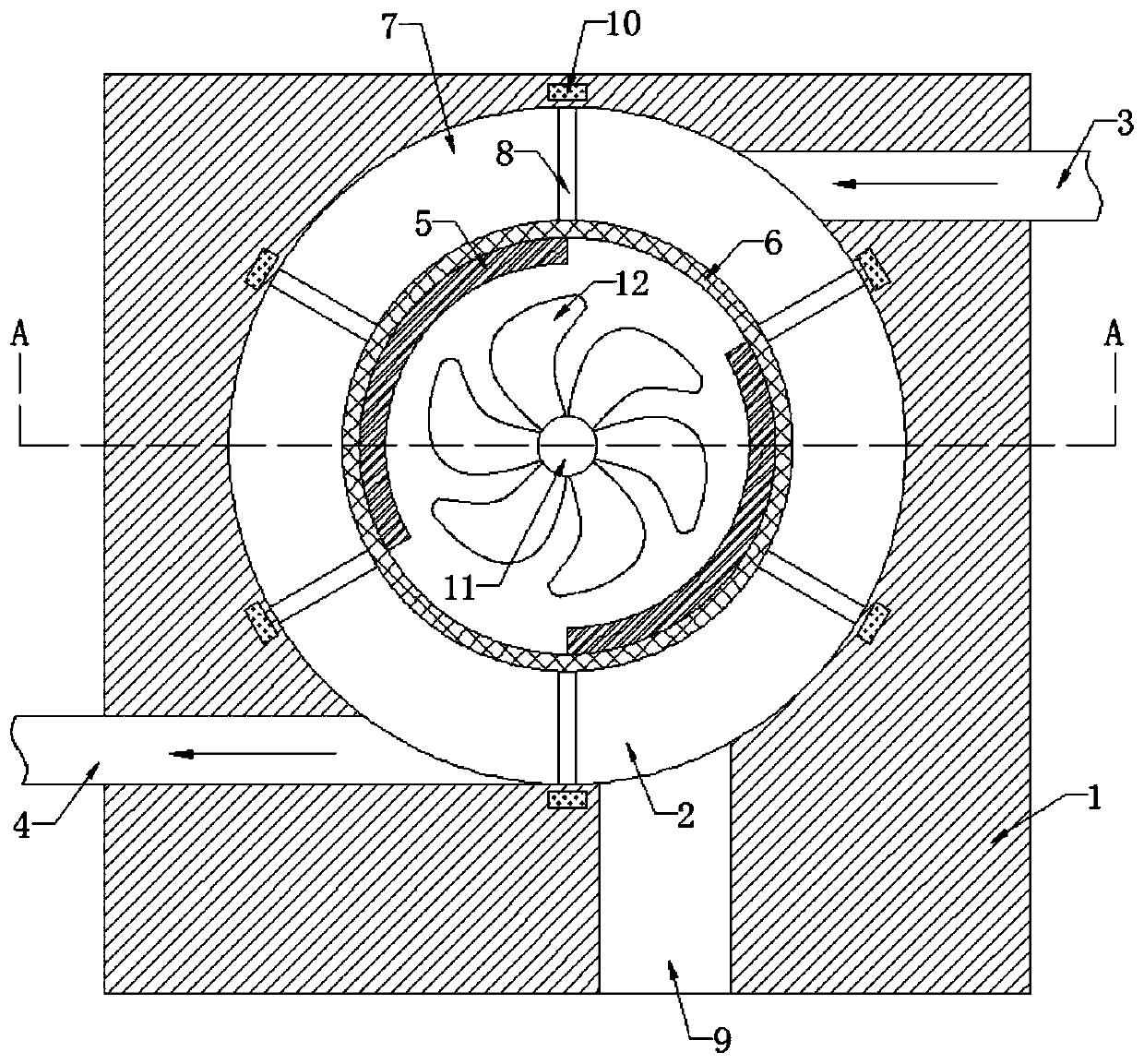

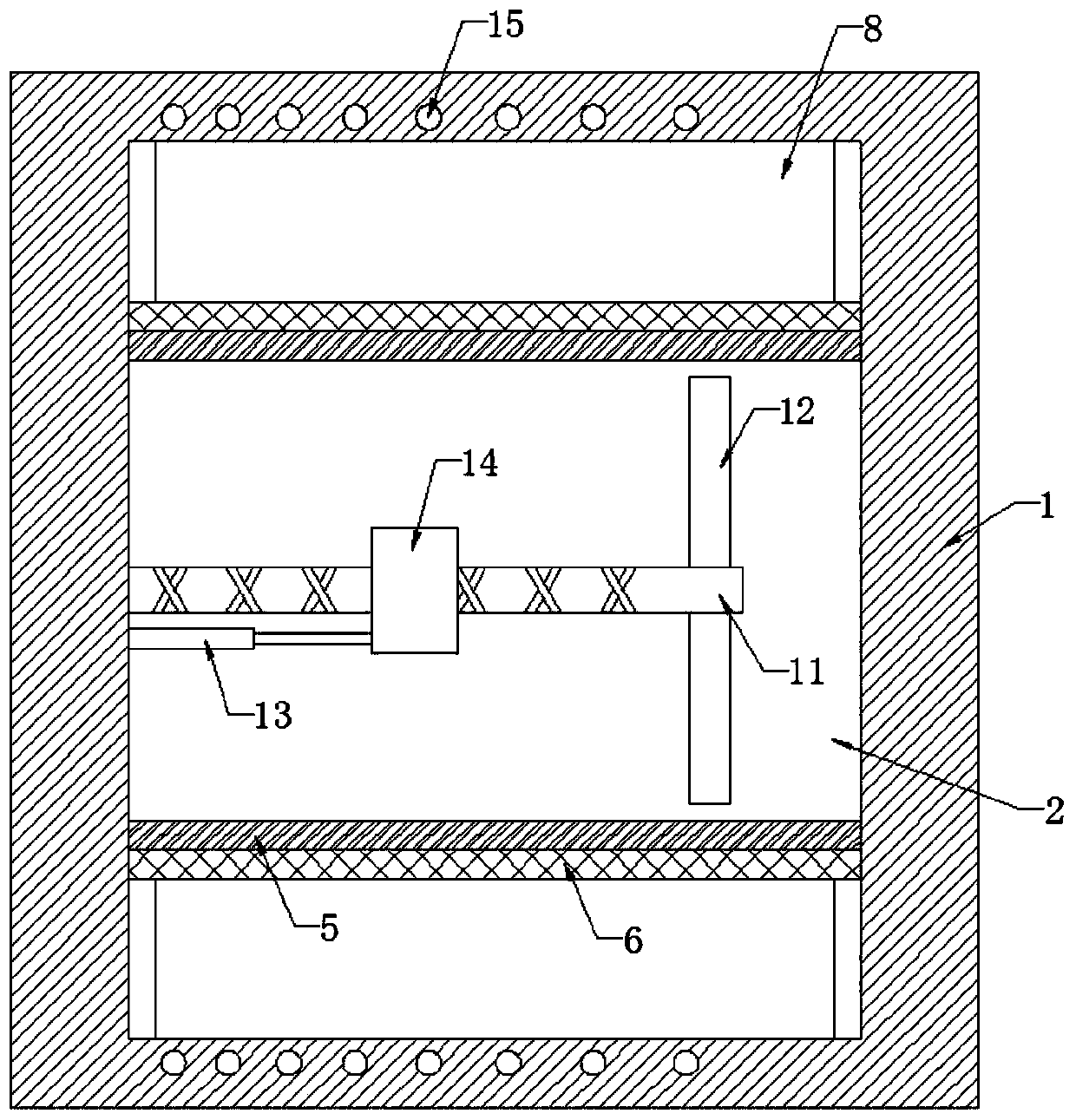

[0020] refer to Figure 1-2 , a water supply and decontamination system for a tower crane spray machine, comprising a housing 1, a circular cavity 2 is opened in the shell 1, a water inlet pipe 3 is connected above the inner wall of the circular cavity 2, and a drainage pipe is connected below the inner wall of the circular cavity 2 Pipe 4, further, the water inlet pipe 3 and the circulating water recovery system, the circulating water recovery system is an existing technology, and will not be repeated here, the drain pipe 4 is connected to the high-pressure pump in the sprayer, and the inner wall of the circular cavity 2 is symmetrically fixedly connected There is an arc-shaped sealing plate 5, and the inner wall of the circular cavity 2 is rotatably connected with an annular filter screen 6, and the annular filter screen 6 is sealed and slidingly connected with the side wall of the sealing plate 5. An annular chamber 7 is formed between them, and the side walls of the annula...

Embodiment 2

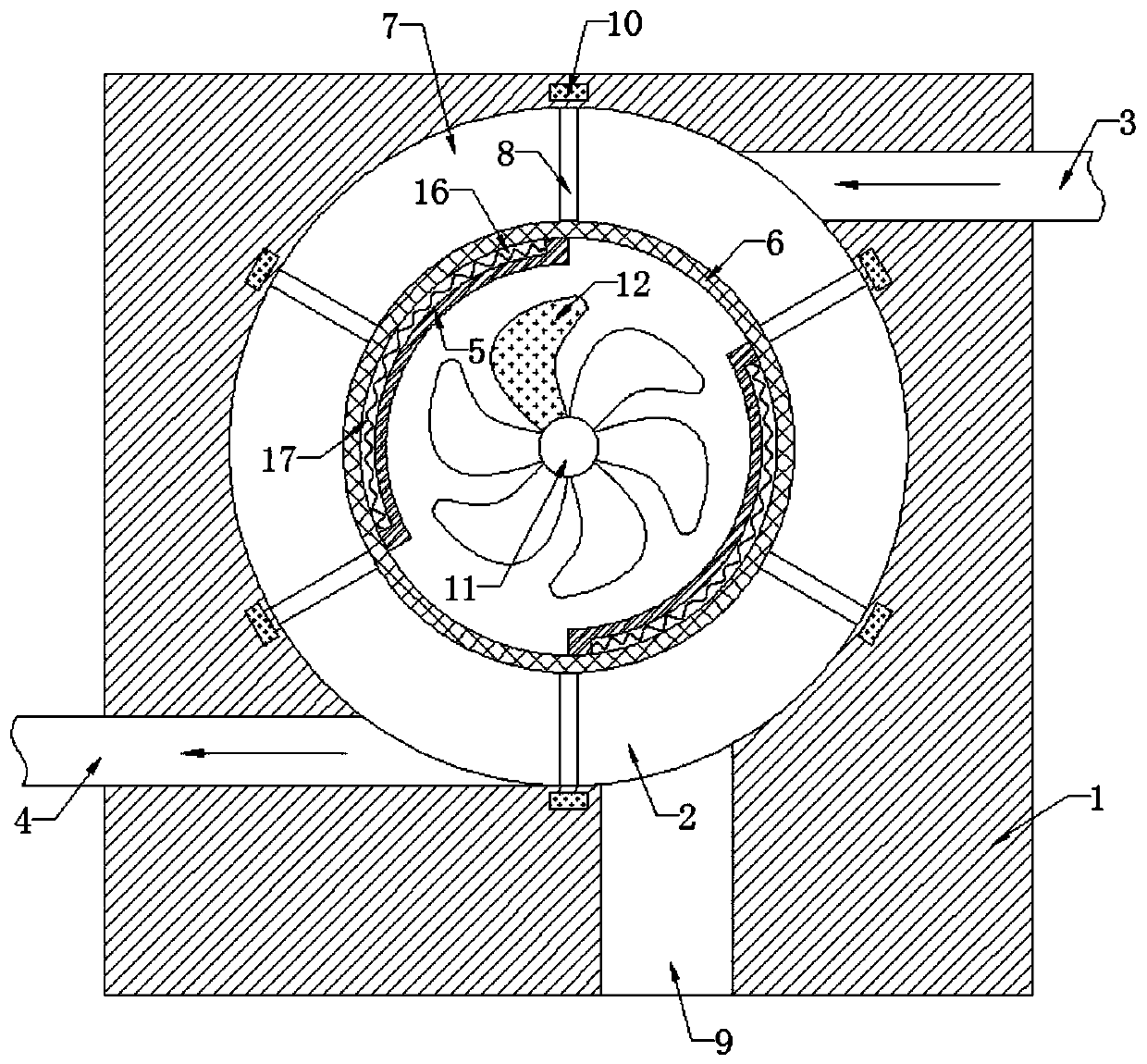

[0025] refer to image 3 , different from Embodiment 1, one of the water wheels 12 is made of magnetic material, the outer wall of the sealing plate 5 is provided with an arc-shaped groove 16, and the inner wall of the arc-shaped groove 16 is fixedly connected with a magnetic vibrating spring 17, and the magnetic vibrating spring 17 is connected with the magnetic vibrating spring 17. A water wheel 12 repels each other with the same pole, and further, when the water wheel 12 keeps rotating, the magnetic vibrating spring 17 is constantly vibrated back and forth in the arc groove 16, and the ring filter screen 6 is knocked and vibrated, and the ring filter screen 6 is vibrated. In addition, every time the partition plate 8 drives the annular filter screen 6 to rotate under the action of gravity, the annular filter screen 6 in contact with the sealing plate 5 will move to the water inlet pipe 3 and the drain pipe 4, so that the annular filter screen 6 can filter The surface can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com