An integrated water and fertilizer irrigation system for greenhouse planting

An irrigation system, water and fertilizer technology, applied in the direction of liquid fertilizer adjustment system, manure treatment, fertilization device, etc., can solve the problems that the planting soil of the root and stem of the plant cannot receive enough water and fertilizer, the effect of the water and fertilizer mixture is reduced, and the plant is overwatered with water and fertilizer, etc. , to avoid excessive local sprinkler irrigation, increase the scope of sprinkler irrigation, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

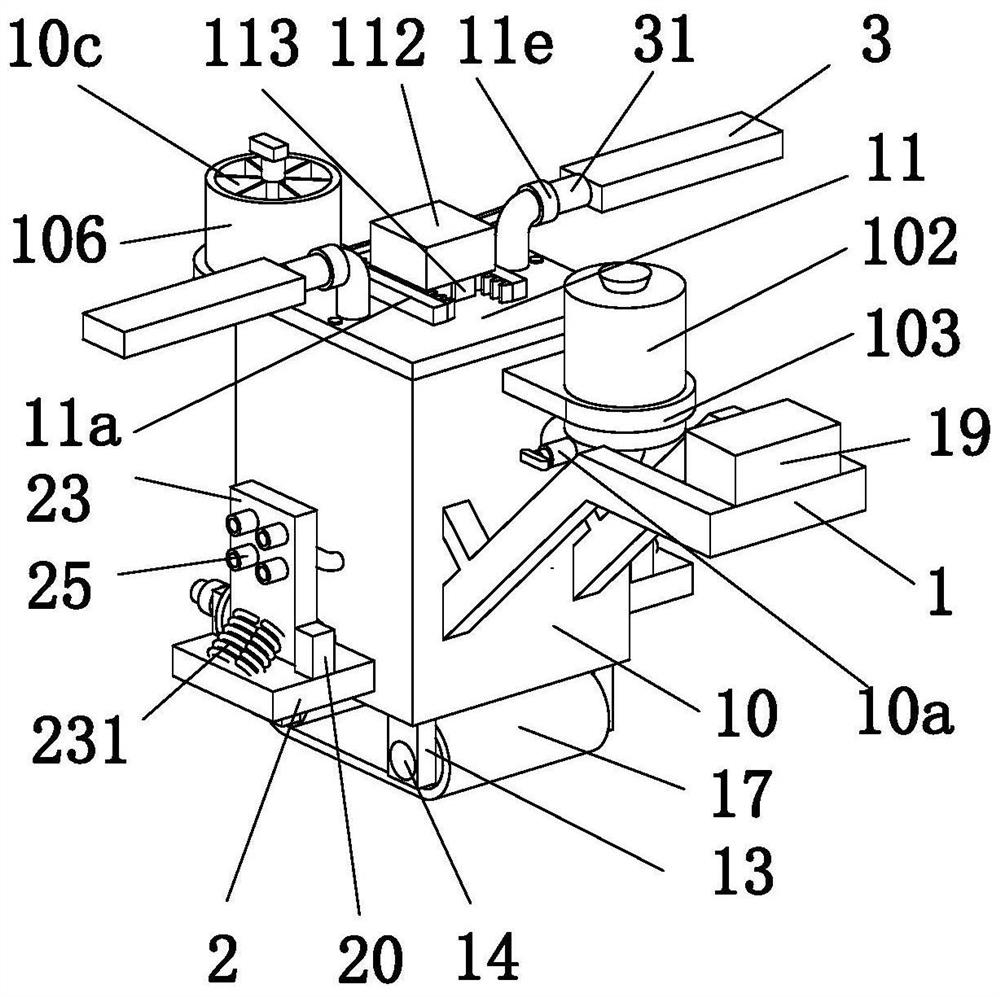

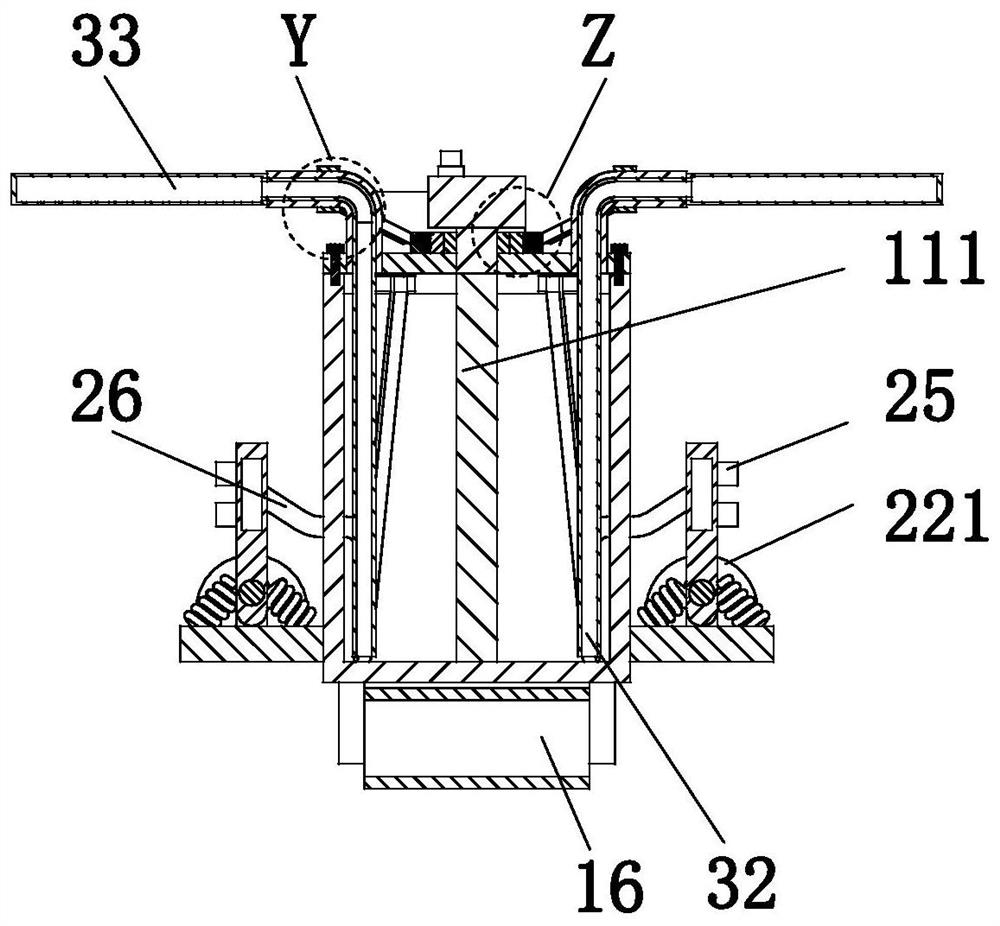

[0033] Such as Figure 1 to Figure 8 As shown, a water and fertilizer integrated irrigation system for greenhouse planting includes a frame 1, a side pouring mechanism 2 and a top pouring mechanism 3. The left and right lower ends of the frame 1 are symmetrically installed with a side pouring mechanism 2, and the middle part of the upper end of the frame 1 is set There is a top pouring mechanism 3.

[0034] The frame 1 includes a liquid storage tank 10, a top plate 11, a bayonet pin 12, a vertical plate 13, a rotating shaft 14, a roller 16, a crawler belt 17, a push handle 18 and a master controller 19, and the upper end surface of the liquid storage tank 10 is fitted by sliding The top plate 11 is installed in the way, and the left and right en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com