Hay feed cutting device

A cutting device and hay feed technology, applied in cutting equipment, agricultural machinery and implements, applications, etc., can solve the problems of low cutting efficiency and cumbersome cutting steps of hay, and achieve fast cutting speed, good cutting effect and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

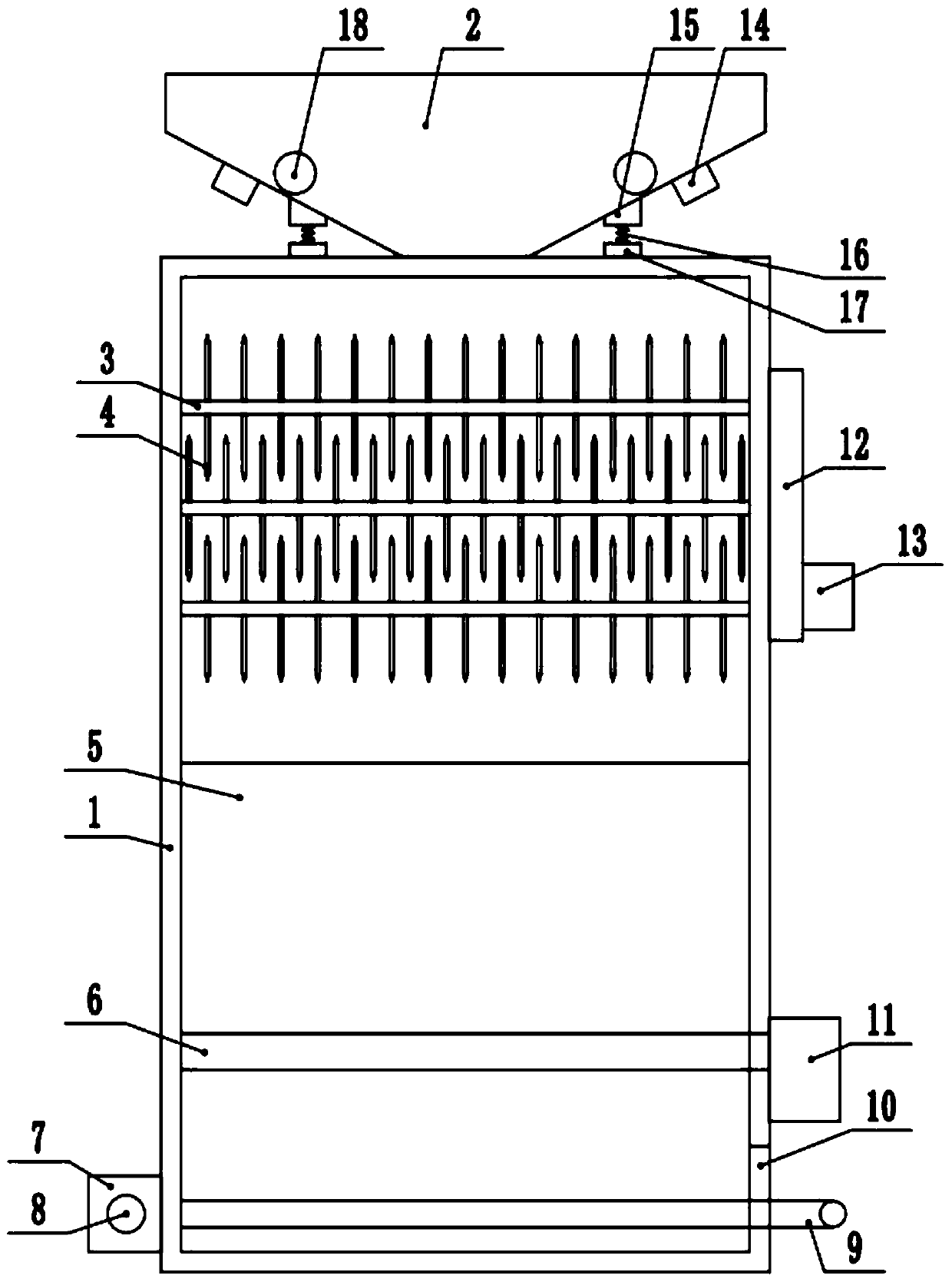

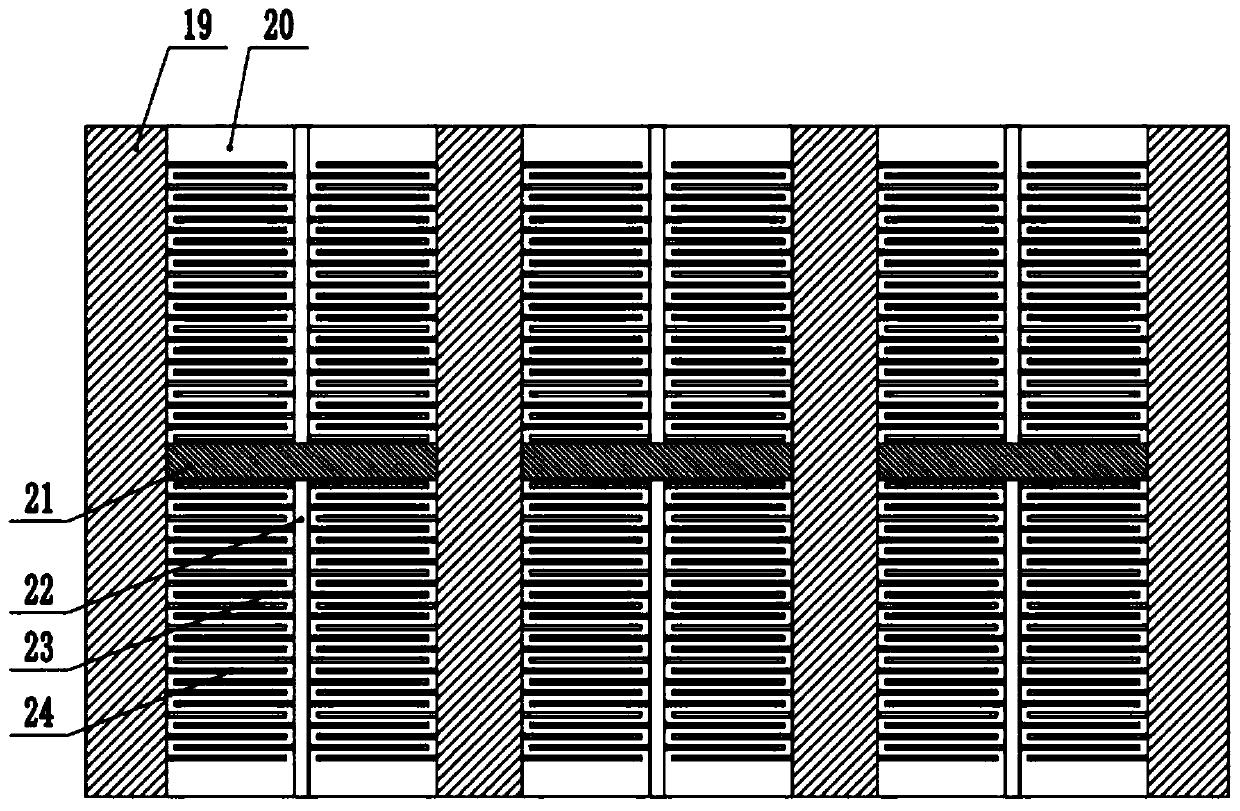

[0024] See Figure 1-3 , A hay forage cutting device, comprising a cutting box 1, the top of the cutting box 1 is fixedly connected to a feeding hopper 2, the feeding hopper 2 is provided with a fast feeding mechanism, and the cutting box 1 is sequentially from top to bottom A primary cutting device and a secondary cutting device 5 are provided, the primary cutting device includes a plurality of horizontally arranged first cutting shafts 3, the outside of the first cutting shaft 3 is fixedly connected to the first cutting blade 4, and the secondary cutting device 5 includes The fixing sleeve 19 is provided with a plurality of cutting passages 20, the middle part of the cutting passage 20 is fixedly connected to the intermediate fixing frame 21, and the intermediate fixing frame 21 is coaxially fixedly connected to the second cutting shaft 22 and the second cutting shaft 22 A plurality of second cutting blades 23 are fixedly connected to the outside of the cutting box 1, a disch...

Embodiment 2

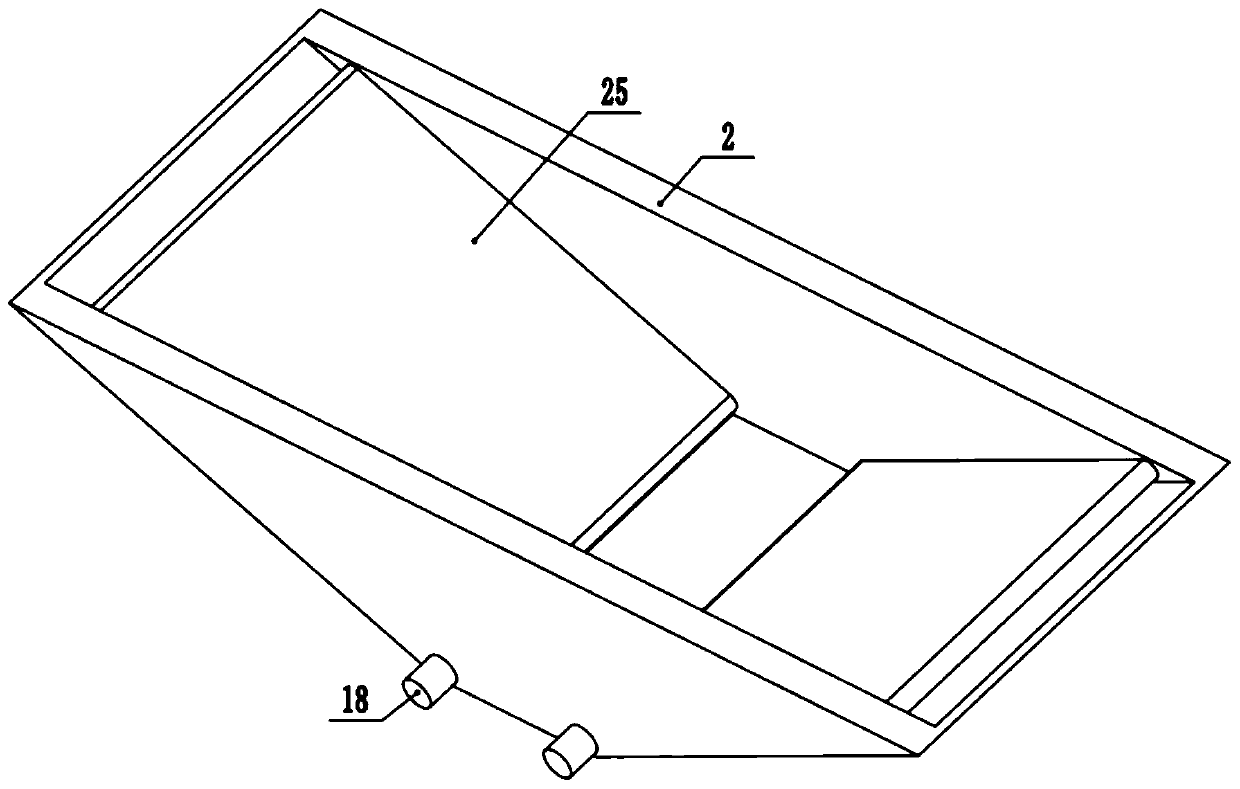

[0027] See Figure 1-3 , The other content of this embodiment is the same as that of embodiment 1, the difference is: the fast feeding mechanism includes a feeding conveyor belt 25 arranged in the feeding hopper 2, and the outside of the feeding hopper 2 is fixedly connected to the first Three driving motors 18, the output shaft of the third driving motor 18 is drivingly connected with the feeding conveyor belt 25.

[0028] The present invention can cut and crush the hay multiple times by providing the primary cutting device and the secondary cutting device 5, the cutting speed is fast and the efficiency is high, the cut hay feed is uniform in length and the cutting effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com