Permanent magnet motor for new energy automobile

A technology of new energy vehicles and permanent magnet motors, applied in electrical components, electromechanical devices, electric components, etc., can solve problems such as difficult heat exchange, increased energy loss, increased safety hazards, etc., to achieve good driving effect and increase service life , the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

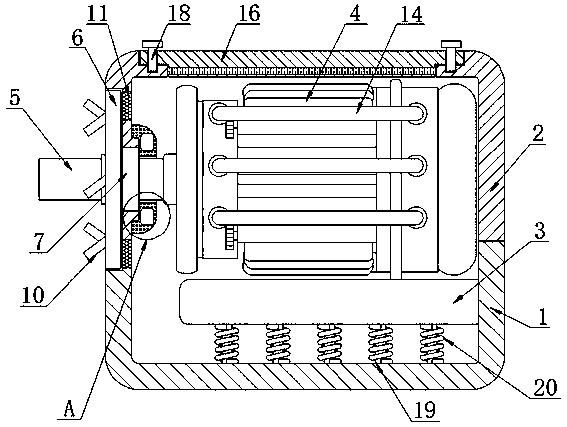

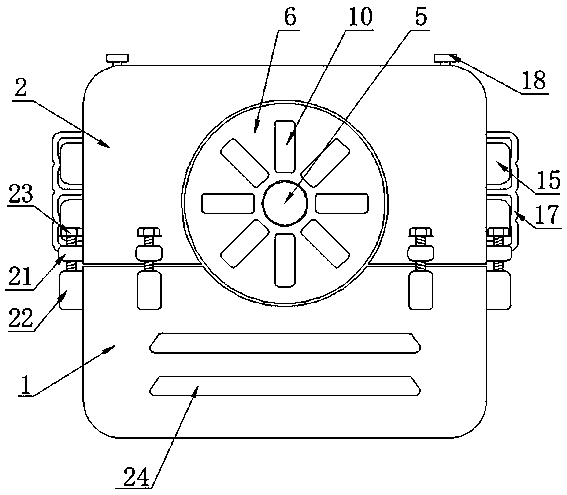

[0033] A permanent magnet motor for new energy vehicles, comprising a lower box 1 and an upper box 2, the surfaces of the upper box 2 and the lower box 1 are fixedly connected with sealing gaskets, the upper box 2 and the lower box 1 are both Made of plastic material, the motor body 4 has a good heat dissipation effect and a good shock absorption effect when in use, and can keep the output shaft 5 lubricated for a long time, which increases the versatility and practicability of the motor. The surface is provided with an air intake groove 24, which is inclined downward, and the inner cavity of the air intake groove 24 is fixedly connected with a filter screen, and there are multiple air intake grooves 24, which are evenly distributed on the surface of the lower box body 1 , the surface of the upper box 2 is fixedly connected with a first fixed block 21, and the surface of the lower box 1 is fixedly connected with a second fixed block 22, and the top of the first fixed block 21 i...

Embodiment 2

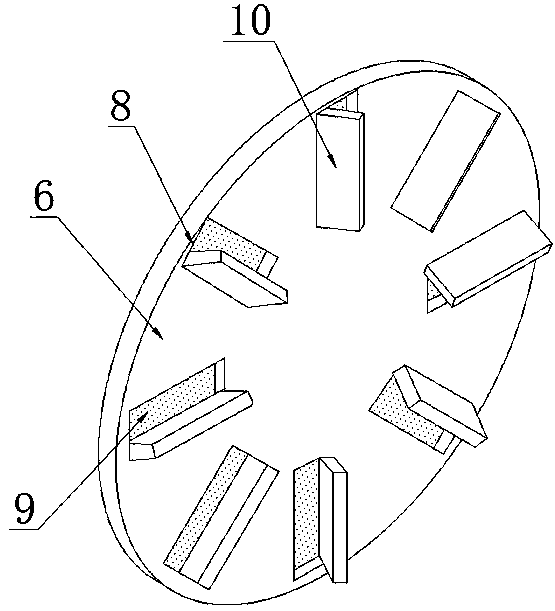

[0035] When working, the motor body 4 drives the output shaft 5 to rotate, and the output shaft 5 rotates in the limit bearing 7. When the output shaft 5 rotates, it drives the disc 6 to rotate, and the disc 6 drives the suction groove 8 and the drainage plate 10 to rotate, forming The eddy current draws the outside air along the air suction groove 8 into the lower box 1 and the upper box 2 along the annular groove 11 after being filtered by the first filter screen 9, and the upper box 2 and the lower box The hot air in 1 is discharged along the air intake groove 24 for air exchange. When the output shaft 5 rotates, the lubricating oil stored in the oil tank 13 in the oil storage tank 12 penetrates into the limit bearing 7 along the pipeline, and the limit bearing 7 Lubricate, the motor body 4 vibrates when it works, and drives the receiving plate 3 to move up and down, the receiving rod 19 slides up and down in the inner cavity of the receiving plate 3, the receiving plate 3 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com