Efficient energy-saving wet curtain humidifying and cooling system for textile workshop and control method of efficient energy-saving wet curtain humidifying and cooling system

A high-efficiency energy-saving, intelligent controller technology, applied in air humidification systems, energy-saving heating/cooling, heating methods, etc., can solve the problems of insufficient humidification, high maintenance costs, and low humidification efficiency of air-conditioning equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

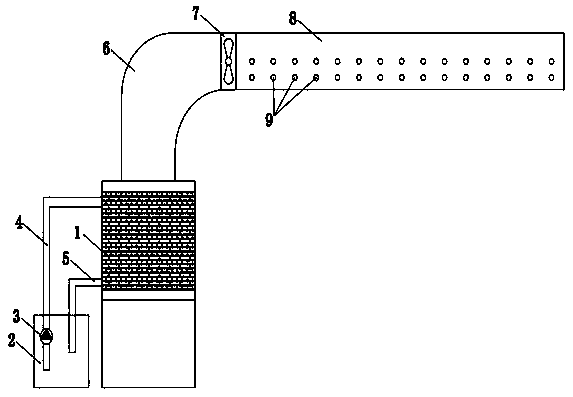

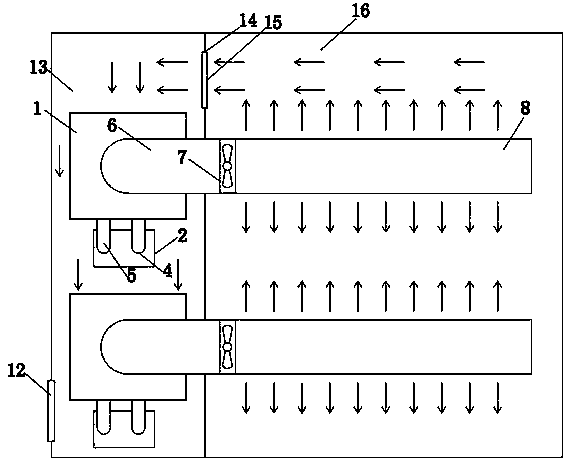

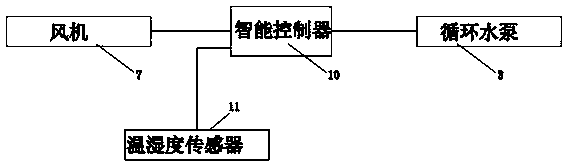

[0021] Such as figure 1 , figure 2 As shown, a high-efficiency energy-saving wet curtain humidification and cooling system and its control method for textile workshops provided by the embodiment of the present invention include a wet curtain 1, a pool 2, a circulating water pump 3, a water supply pipe 4, and a return water pipe 5. The wet The curtain 1 is installed in the air duct 13, the air duct 13 is provided with an indoor wind regulating window 14 communicated with the workshop 16, the indoor wind regulating window 14 is provided with a dust filter 15, the wet curtain 1 and the pool 2 A water supply pipe 4 and a water return pipe 5 are provided between them. The water supply pipe 4 is provided with a circulating water pump 3, and the circulating water pump 3 supplies circulating water to the wet curtain 1. The wet curtain 1 is connected to the main air duct 6. The main air duct 6 is provided with a fan 7, the fan 7 is an axial flow fan, the main air duct 6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com