Disc buckling support system and construction system used for open-cut tunnel

A support system and open-cut tunnel technology, applied in tunnels, tunnel linings, artificial islands, etc., can solve the problems of wasting construction time, slowing down the construction progress, and speeding up the progress of the construction period, so as to reduce the difficulty of construction, speed up the progress of the construction period, and solve the The effect of closed mode problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

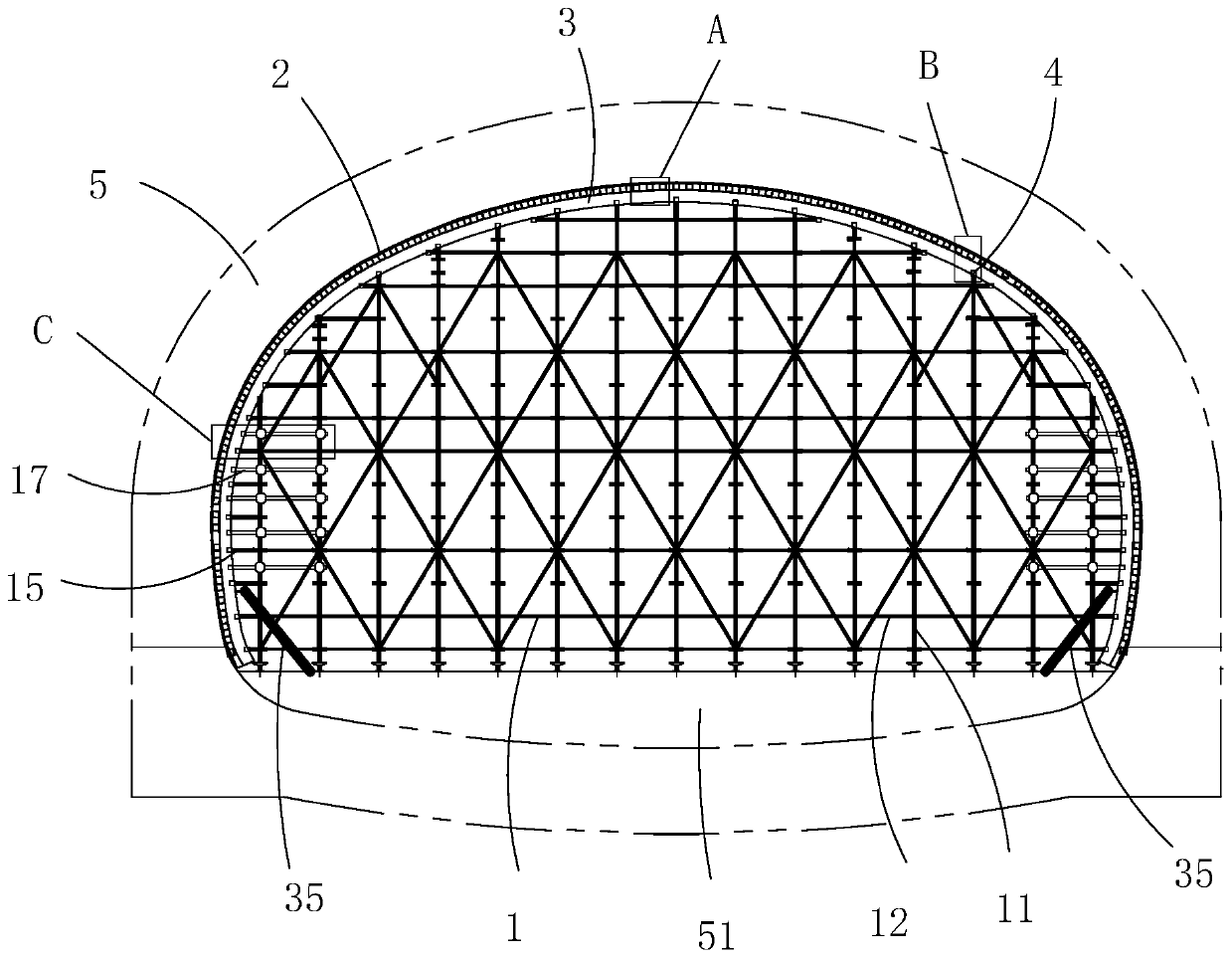

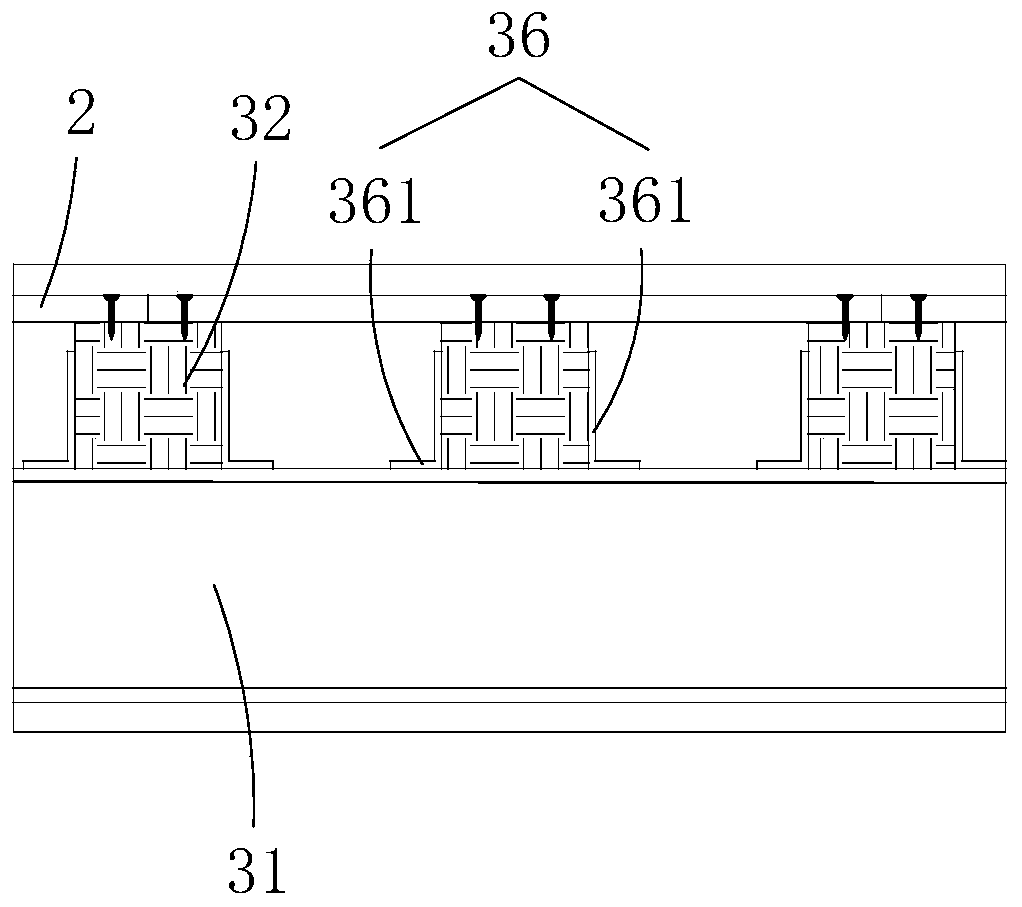

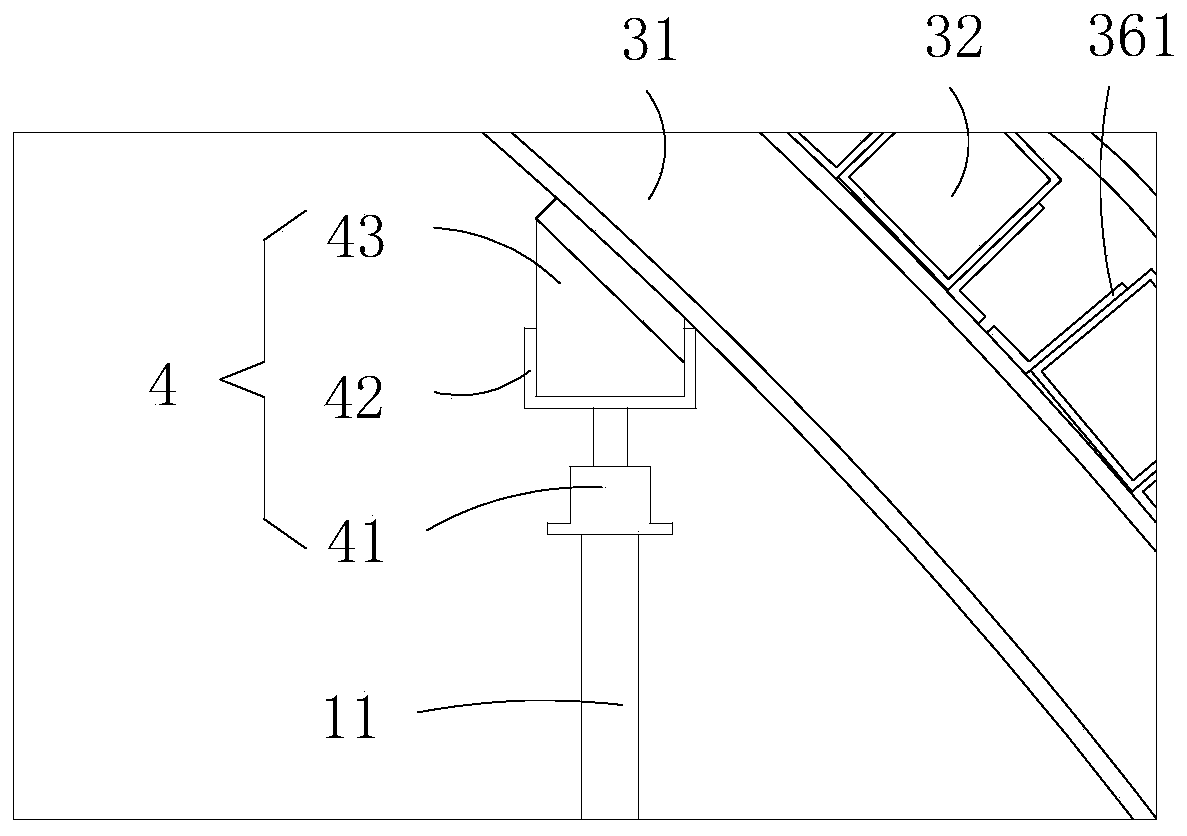

[0063] Such as Figure 1-11 As shown, a coil support system for open-cut tunnels described in this embodiment includes a coil support 1, and a support truss 3 is connected to the support truss 1 on the support truss 3, and the outside of the support truss 3 The support is connected with an arch formwork 2, the arch formwork 2 is adapted to the shape of the inner wall of the tunnel 5, and the support truss 3 includes a main beam 31 arranged along the inner wall of the tunnel 5 and a longitudinal arrangement along the inner wall of the tunnel 5. The secondary beam 32, the main beam 31 is supported and connected with the secondary beam 32, the buckle bracket 1 is supported and connected with the main beam 31, and the arch formwork 2 is connected to the outside of the secondary beam 32, The buckle bracket 1 includes a vertical bar 11, a horizontal bar 12 and a vertical bar 13, the horizontal bar 12 is arranged horizontally along the cross-sectional direction of the tunnel 5, and t...

Embodiment 2

[0105] Such as Figure 12 As shown, a construction system for open-cut tunnels described in this embodiment includes an outer mold trolley 6 and a buckle support system as described in this application, the outer mold trolley 6 and the buckle There is a pouring space for pouring the structure of the tunnel 5 between the support systems.

[0106] Beneficial effects of this embodiment: a construction system for open-cut tunnels described in this application, the outer mold uses the outer mold trolley 6, and the inner mold uses the buckle support system described in the application. The combination of bracket 1, support truss 3 and arch formwork 2 replaces the inner mold trolley. Compared with the inner mold trolley, the buckle-type bracket 1 does not affect other construction panels when it is installed or disassembled, so that the trolley can be advanced Multi-point simultaneous operation greatly speeds up the construction schedule, good economy, and easy turnover. At the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com