Cold-resistant PVC oil-proof film with high tensile strength and preparation process thereof

A technology of tensile strength and oil-proof film, applied in the coating and other directions, can solve the problems of cold resistance, poor tensile strength, use effects, etc., to achieve enhanced tensile strength and cold resistance, enhanced tensile strength, and rebound speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

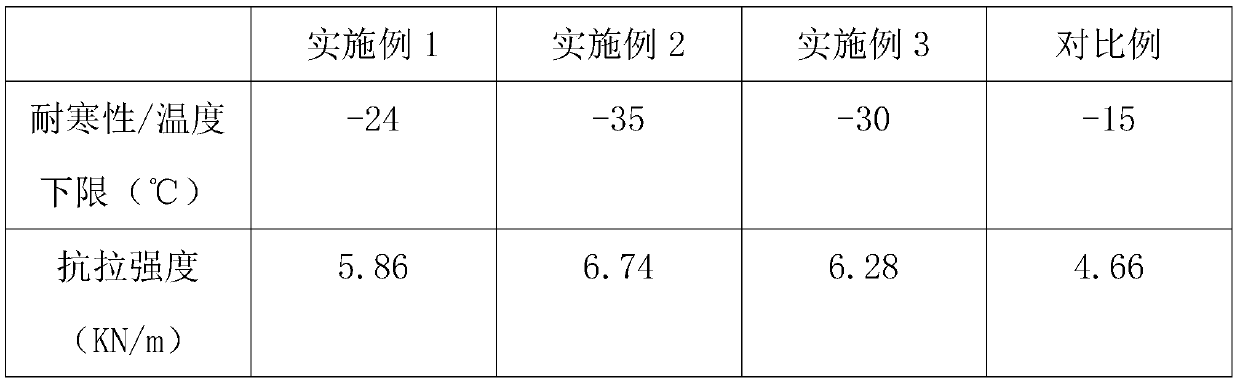

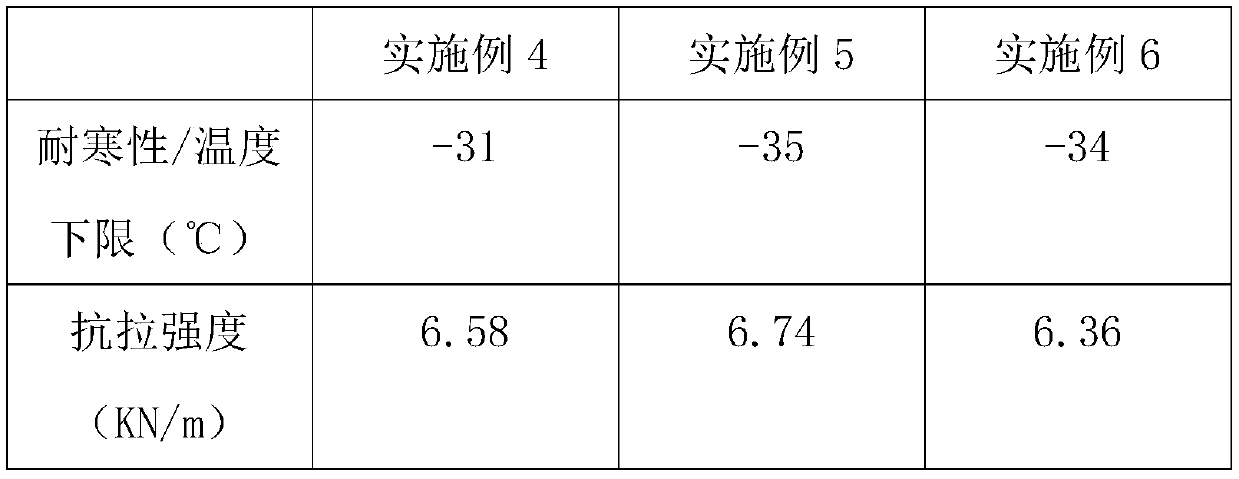

Embodiment 1

[0023] The invention provides a cold-resistant PVC oil-proof film with high tensile strength, comprising a base film and an elastic film layer, the elastic film layer is coated on the surface of the base film, and the components of the preparation raw materials of the base film are in parts by mass The count is: 50 parts of resin, 5 parts of cold-resistant agent, 6 parts of main plasticizer, 3 parts of modifier, 0.8 part of filler, and appropriate amount of auxiliary plasticizer.

[0024] The elastic film layer is a highly elastic resin film, and its base material is any one of polyvinyl acetal resin, high elastic water-based polyurethane resin and polypropylene modified silicone polymer.

[0025] The resin includes PVC resin and EVA resin, the amount ratio of the PVC resin to the EVA resin is 5:1, and the average degree of polymerization of the PVC resin is greater than 2000.

[0026] The cold-resistant agent is a mixture of EP, triazine-5, tricresyl phosphate, ethylene octas...

Embodiment 2

[0037] The invention provides a cold-resistant PVC oil-proof film with high tensile strength, comprising a base film and an elastic film layer, the elastic film layer is coated on the surface of the base film, and the components of the preparation raw materials of the base film are in parts by mass The count is: 65 parts of resin, 7 parts of cold-resistant agent, 8 parts of main plasticizer, 4 parts of modifier, 1.2 parts of filler, and appropriate amount of auxiliary plasticizer.

[0038] The elastic film layer is a highly elastic resin film, and its base material is any one of polyvinyl acetal resin, high elastic water-based polyurethane resin and polypropylene modified silicone polymer.

[0039] The resin includes PVC resin and EVA resin, the amount ratio of the PVC resin to the EVA resin is 5:1, and the average degree of polymerization of the PVC resin is greater than 2000.

[0040]The cold-resistant agent is a mixture of EP, triazine-5, tricresyl phosphate, ethylene octas...

Embodiment 3

[0051] The invention provides a cold-resistant PVC oil-proof film with high tensile strength, comprising a base film and an elastic film layer, the elastic film layer is coated on the surface of the base film, and the components of the preparation raw materials of the base film are in parts by mass The count is: 80 parts of resin, 8 parts of cold-resistant agent, 10 parts of main plasticizer, 5 parts of modifier, 1.5 parts of filler, and appropriate amount of auxiliary plasticizer.

[0052] The elastic film layer is a highly elastic resin film, and its base material is any one of polyvinyl acetal resin, high elastic water-based polyurethane resin and polypropylene modified silicone polymer.

[0053] The resin includes PVC resin and EVA resin, the amount ratio of the PVC resin to the EVA resin is 5:1, and the average degree of polymerization of the PVC resin is greater than 2000.

[0054] The cold-resistant agent is a mixture of EP, triazine-5, tricresyl phosphate, ethylene oct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com