Garbage compression equipment capable of improving compression efficiency

A technology of garbage compression and compression efficiency, which is applied in the direction of garbage transmission, garbage collection, presses, etc., which can solve the problems of increasing the number of pressing down of the pressing plate, affecting the normal life of nearby residents, and increasing the energy consumption of the hydraulic tank, so as to reduce time and eliminate waste. Odor, the effect of improving compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

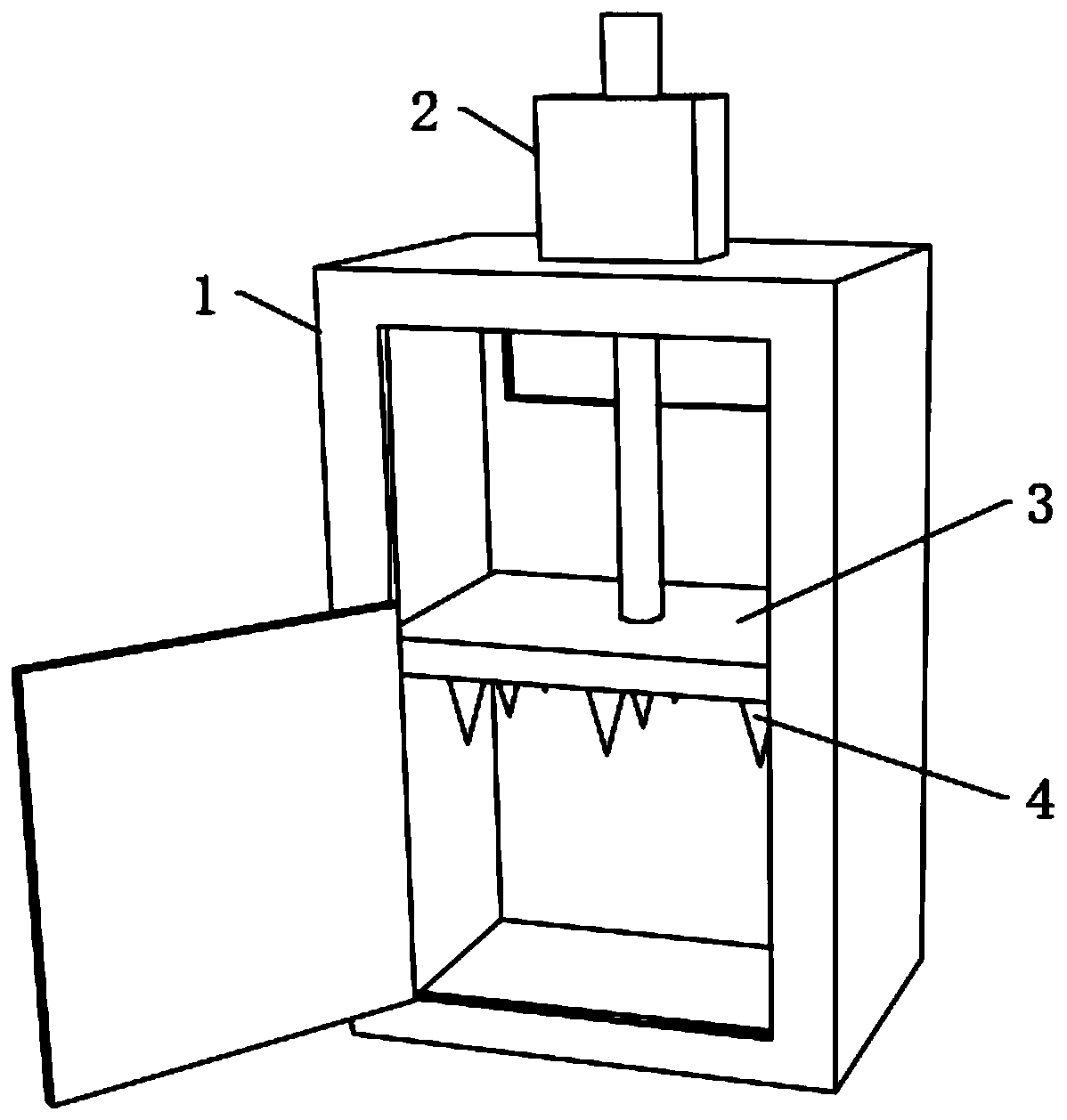

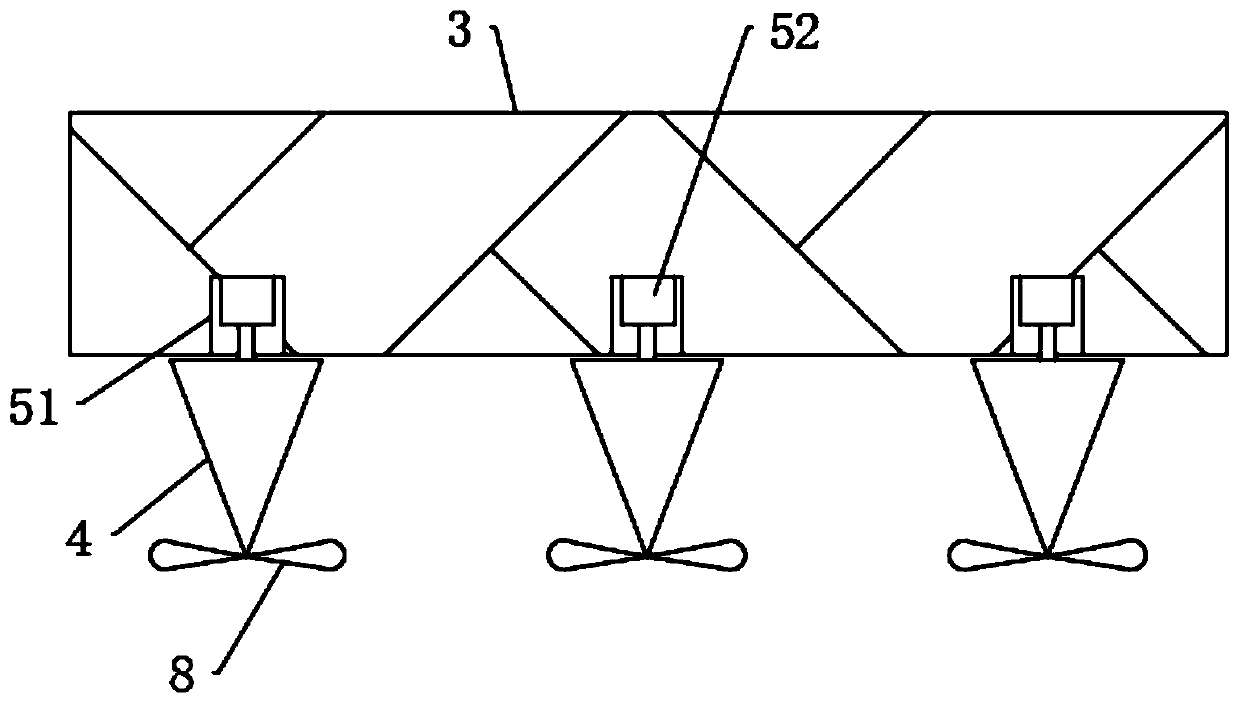

[0042] see figure 1 , a garbage compression device that can improve compression efficiency, including a garbage compression box body 1 with a switch door, a controller is installed on the outer end of the garbage compression box body 1, and a hydraulic tank 2 and a micro-motor 52 are electrically connected to the controller , the upper end of the garbage compression box body 1 is equipped with a hydraulic tank 2, the output end of the hydraulic box 2 runs through the inner top of the garbage compression box body 1 and is fixedly connected with a pressure plate 3, the pressure plate 3 is slidingly connected with the inner wall of the garbage compression box body 1, and the pressure plate 3 is lowered There are multiple sets of evenly distributed hollow conical columns 4 on the side.

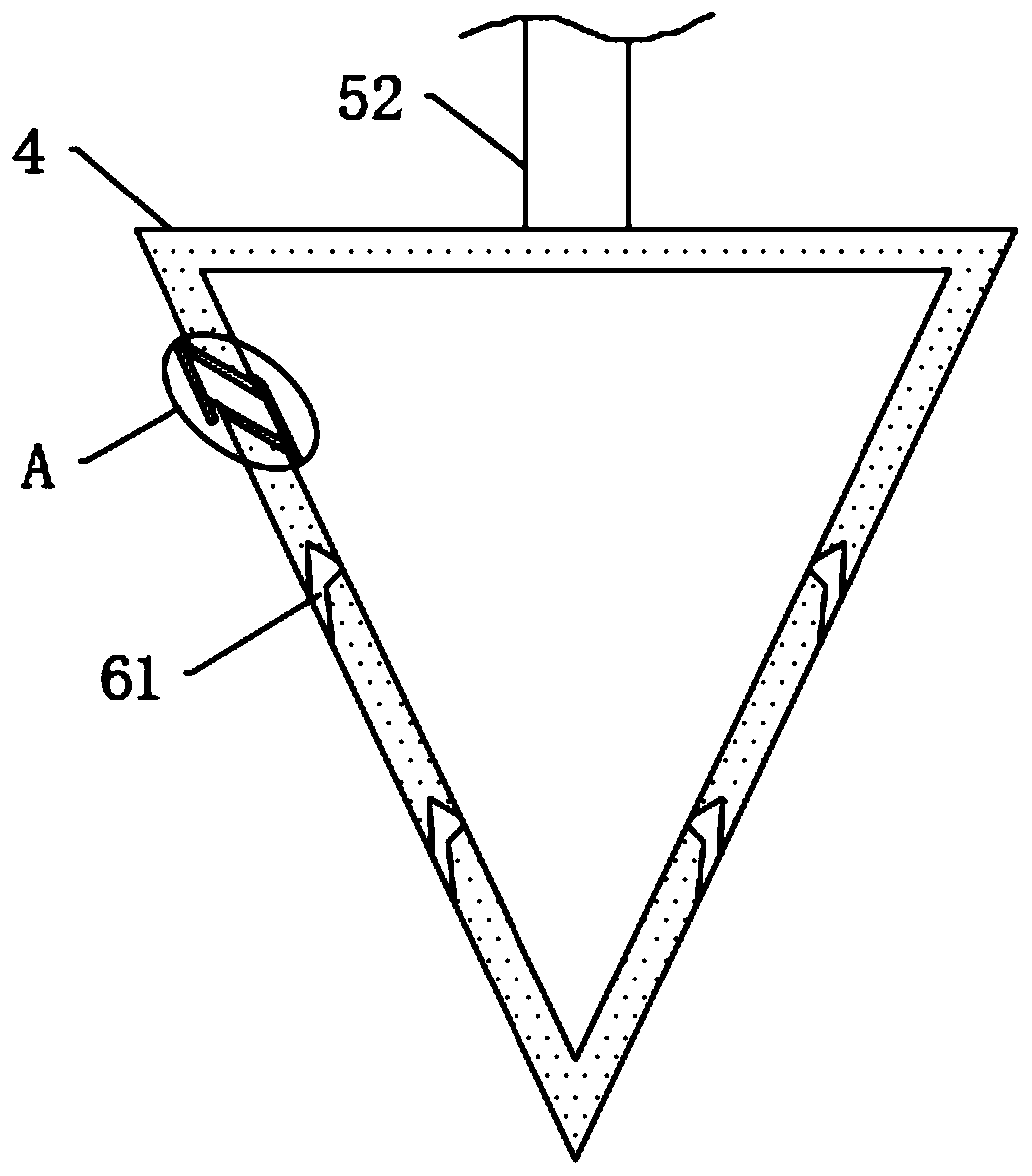

[0043] see figure 2 , the bottom end of the pressing plate 3 is dug with a plurality of groups of installation grooves 51 corresponding to the hollow conical column 4, and the top end of the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com