Combined pipe cutting method and system

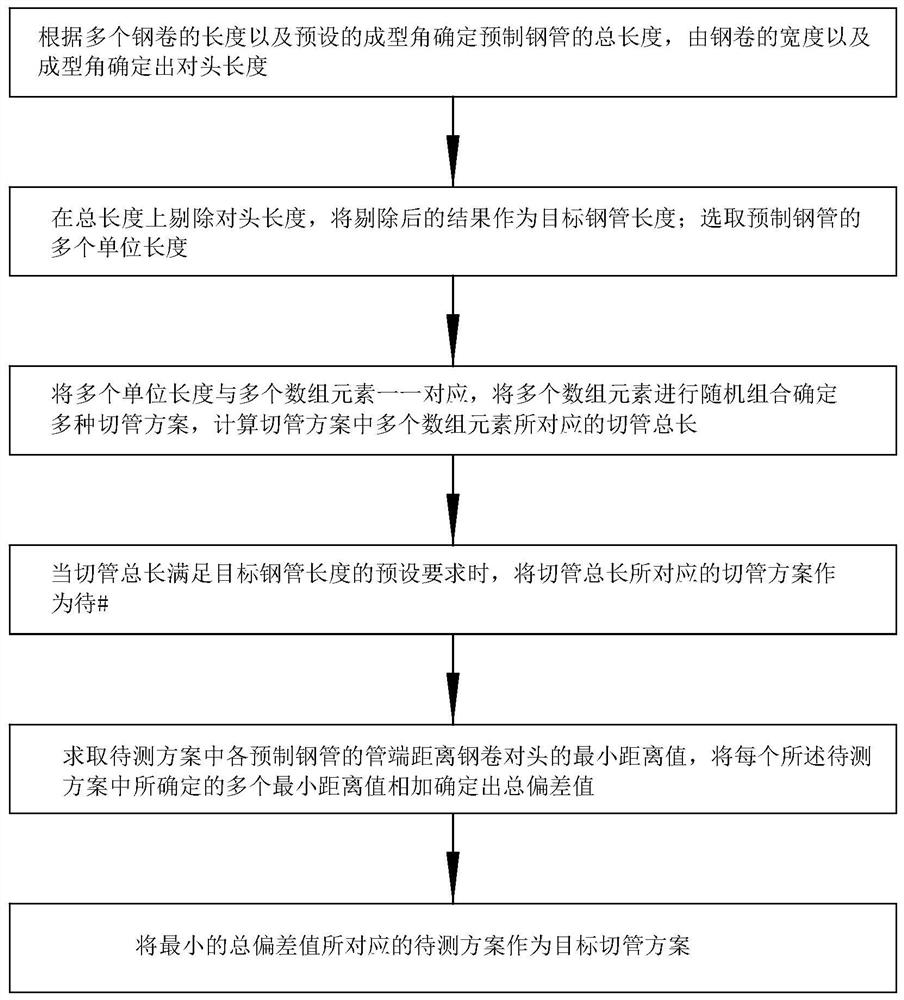

A combined method and pipe cutting technology, which is applied in pipe shearing devices, shearing devices, manufacturing tools, etc., can solve the problems of high cost and large amount of steel material, and achieve the goals of reducing loss, improving product quality, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0060] As a specific embodiment of the pipe cutting combination method provided by the present invention, the calculation formula of the target steel pipe length is:

[0061] L 5 = L 2 -(m-1)×L 4

[0062] Among them, L 5 Indicates the target steel pipe length, and m indicates the number of steel coils.

[0063] In this application, the spiral steel pipe is produced continuously, so multiple steel coils need to be connected end-to-end to form a whole. Finally, when there is a butt joint at the pipe end of the cut steel coil, it needs to be cut off, which results in a shorter final length of the steel pipe. If m steel coils are connected end-to-end, a total of m-1 steel coil pairs will be generated. For this reason, in this application, on the basis of the total length, the m-1 lengths of the opposite heads are subtracted, that is, the arrangement and combination of the steel pipe cutting sequence is carried out under the condition that the opposite ends have been cut off,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com