Safety production risk monitoring and early warning equipment based on risk assessment model

A risk assessment model and technology for safe production, applied in mechanical equipment, alarms, instruments, etc., can solve problems such as inability to perform combined detection and multi-data detection, limited application scenarios, and unsatisfactory early warning effects, and improve detection diversity. performance, improve accuracy, and improve detection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

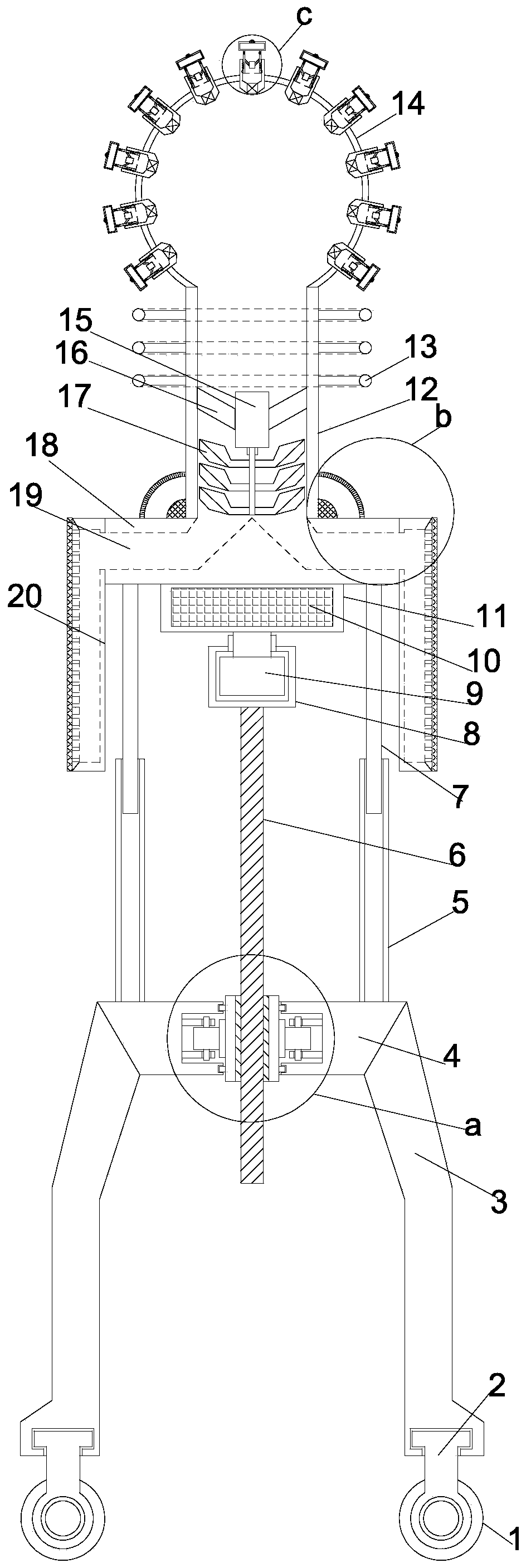

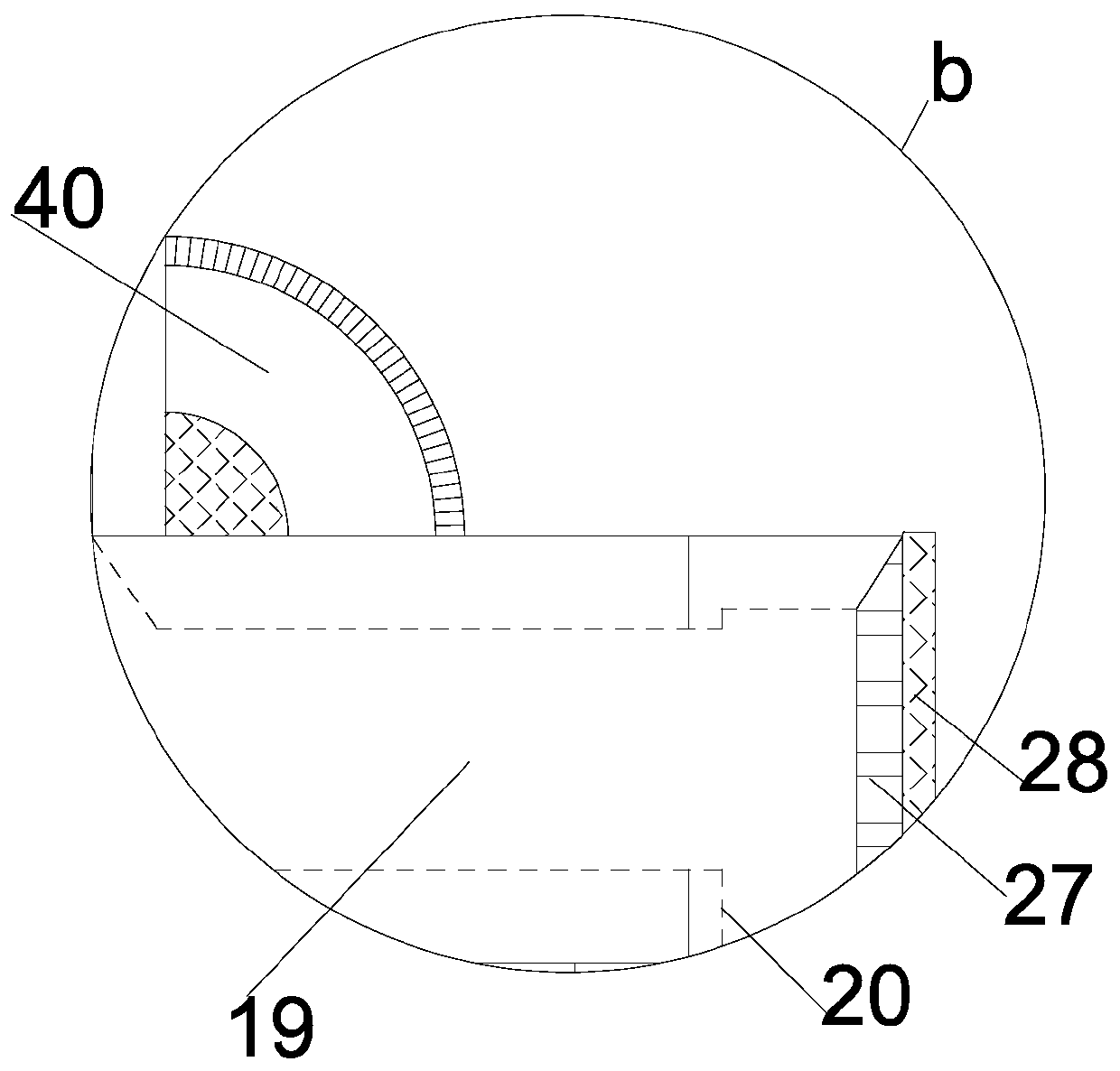

[0024] see Figure 1~5 , in an embodiment of the present invention, a safety production risk monitoring and early warning device based on a risk assessment model includes a horizontally arranged support mounting plate 4, a number of support mounting columns 3 are arranged at equal angles on the edge of the support mounting plate 4, and the support mounting columns 3 They are all arranged vertically, and the lower ends of the supporting installation columns 3 are provided with steering wheel frames 2, and the lower ends of the steering wheel frames 2 are provided with steering mobile wheels 1 through rotating shafts, and a lifting device is installed horizontally directly above the supporting mounting plate 4. plate 18, the upper middle position of the lifting installation plate 18 is vertically provided with a guide installation cylinder 12, the lower end middle position of the lifting installation plate 18 is horizontally provided with a lifting transmission plate 11, and the ...

Embodiment 2

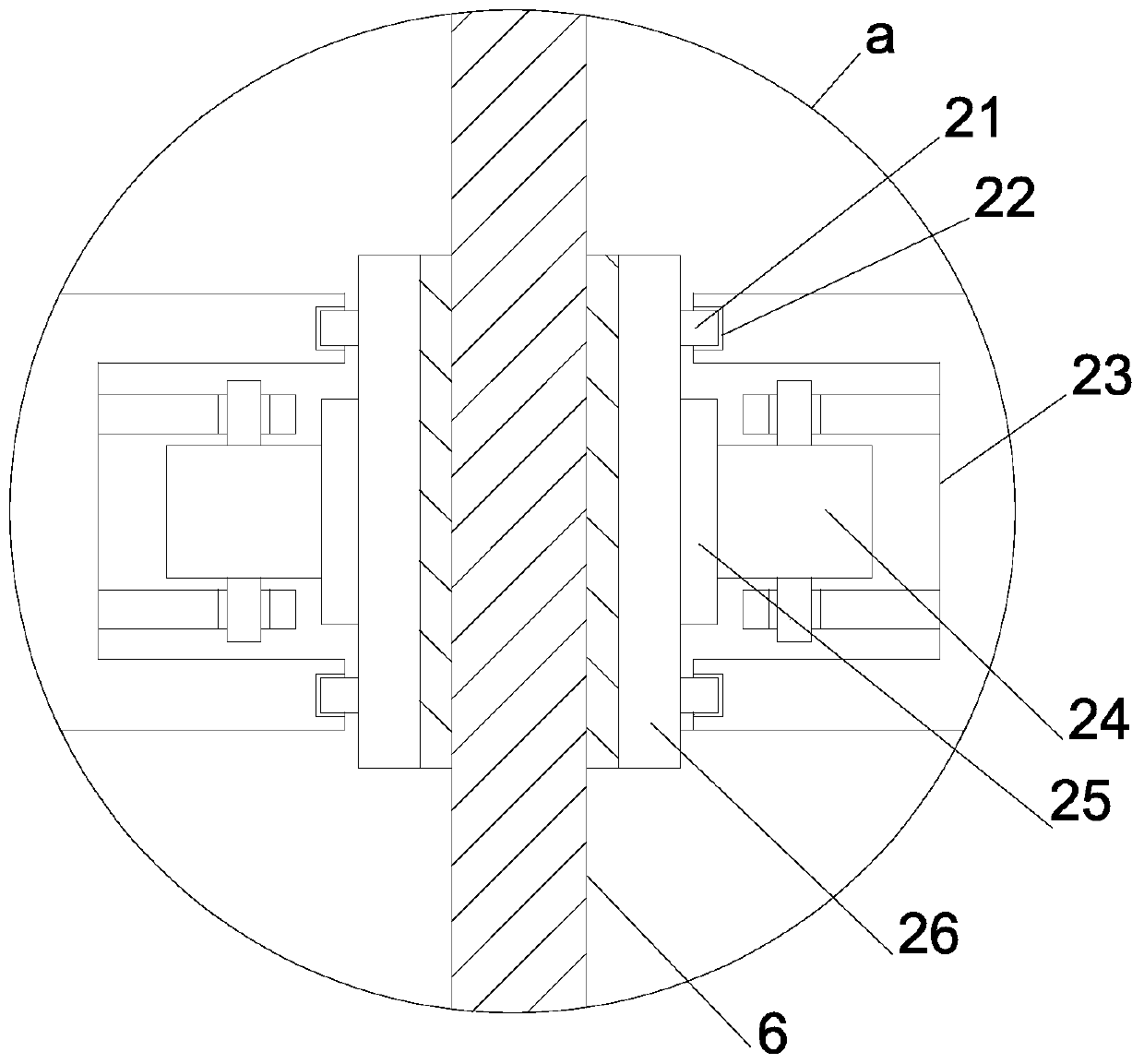

[0027] On the basis of Embodiment 1, the driving gear 24 and the rotating gear ring 25 are engaged and transmitted, so that the lifting screw cylinder 26 cooperates with the lifting stud 6 to realize the height adjustment of the lifting stud 6, and cooperates with the limit bearing sleeve 8 and the limit The rotating shaft 9 realizes the overall adjustment of the detection height. At this time, under the cooperation of the lifting guide cylinder 5 and the lifting guide column 7, the stable lifting adjustment of the device is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com