Manufacturing method of rock cross fracture simulation model

A simulation model and cross-crack technology, applied in teaching models, suspension and porous material analysis, instruments, etc., can solve problems such as inapplicable crack network flow laws, and achieve accurate disassembly and assembly functions, simple procedures, and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

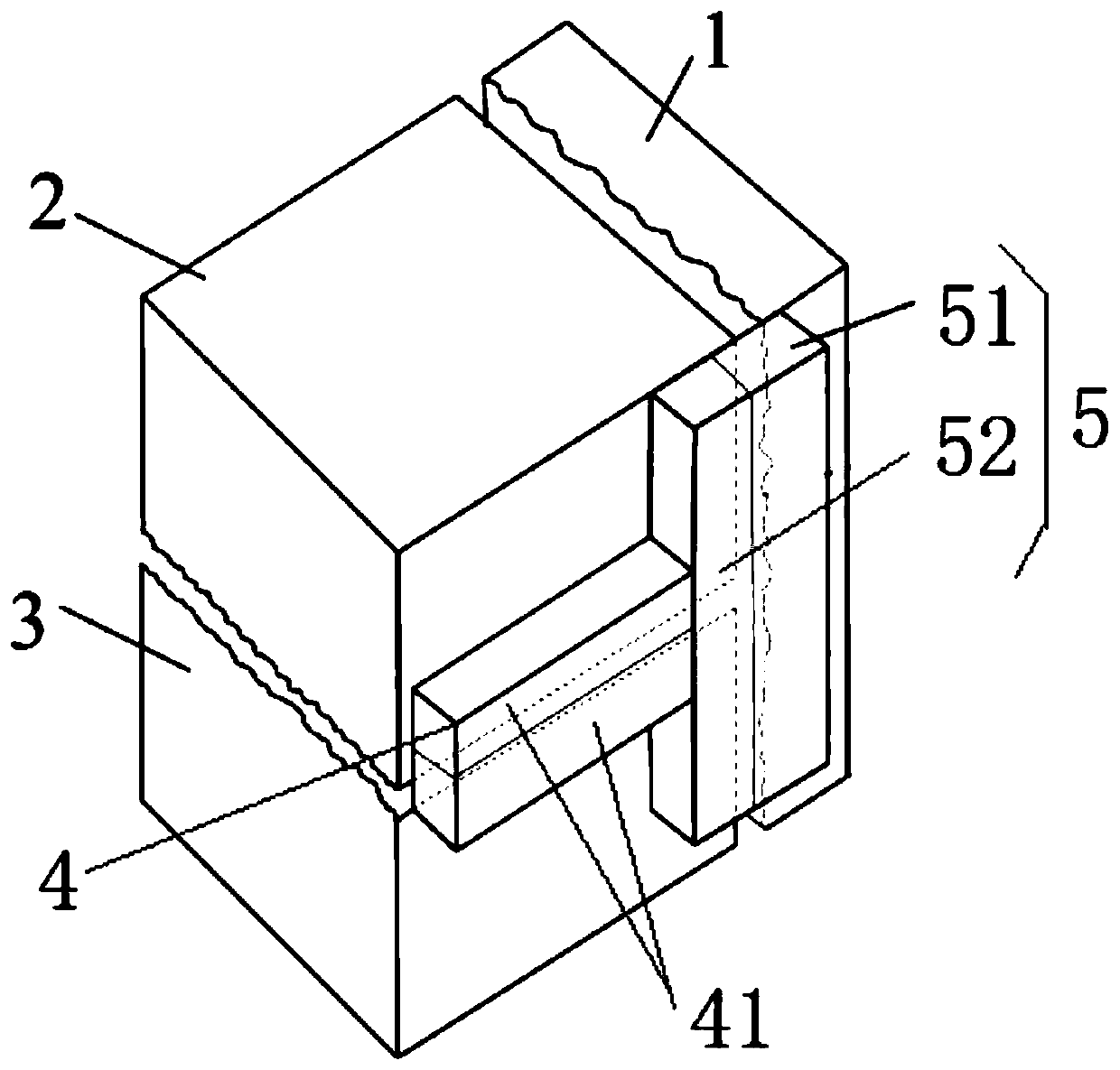

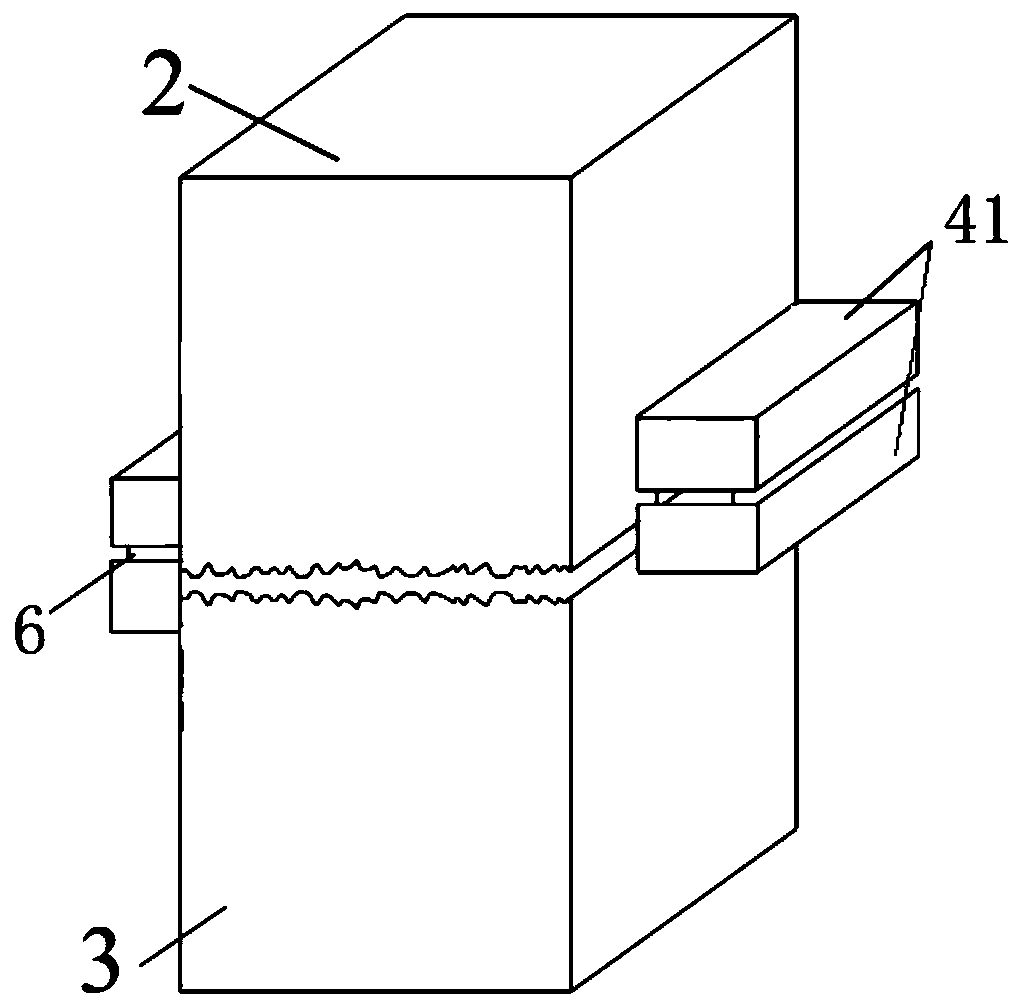

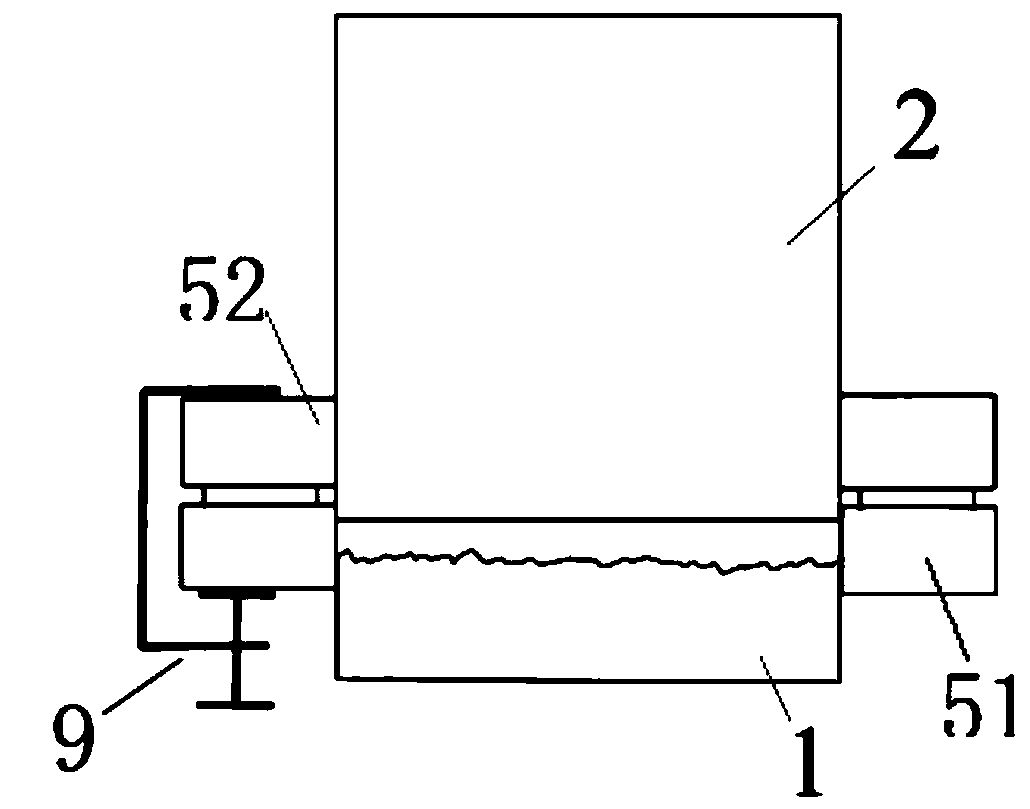

[0038] Such as Figure 1-5 As shown, a method for making a rock cross-crack simulation model includes the following steps:

[0039] 1) Obtain rough rock fracture structure plane

[0040] Artificial rough surface is made (in other embodiments also can choose to have the stone material of natural rough surface), choose the rock of standard cuboid size (long L, wide W, high H), adopt the hammer of lychee bark on the stone material surface (L× W face) knocking, make stone material surface form the rough surface that is shaped like lychee bark, obtain desired rock. By artificially selecting the surface structure of the percussion hammer, controlling and adjusting the percussion density and strength, the rough structure surface required for research can be obtained.

[0041] 2) Copy the rock fracture structure plane

[0042] The rock structural surface is re-engraved using the current mature silica gel molding technology to form a silica gel model mold. After the silicone sample...

Embodiment 2

[0054] Such as Figure 1-5 As shown, a method for making a rock cross-crack simulation model includes the following steps:

[0055] 1) Obtain rough rock fracture structure plane

[0056] Manufactured by artificial rough surface, select the standard cuboid size (length 20cm, width 20cm, height 5cm) of the stone, use the hammer of lychee skin to knock on the surface of the stone (20cm×20cm surface), so that the surface of the stone forms a rough surface shaped like lychee skin , to get the required rock 7. By artificially selecting the surface structure of the percussion hammer, controlling and adjusting the percussion density and strength, the rough structure surface required for research can be obtained.

[0057] 2) Copy the rock fracture structure plane

[0058] The rock structural surface is re-engraved by the current mature silica gel mold turning technology to form a silica gel model mold 8. After the silicone sample mold 8 is completely cured, the rock 7 is taken out,...

Embodiment 3

[0064] The difference between this embodiment and embodiments 1 and 2 is that the upper block 2 or the lower block 3 forming the horizontal fissure does not contain a joint surface, and only one side of the horizontal fissure has a rough joint surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com