Direction-adjustable self-closing pressure gauge valve

A pressure gauge and self-closing technology, which is applied in elastic deformation meter type fluid pressure measurement, fluid pressure measurement, fluid pressure measurement through mechanical components, etc., can solve the problems of inconvenient disassembly and assembly, reduce the possibility of rotation, reduce the Decrease in effect, increase in effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

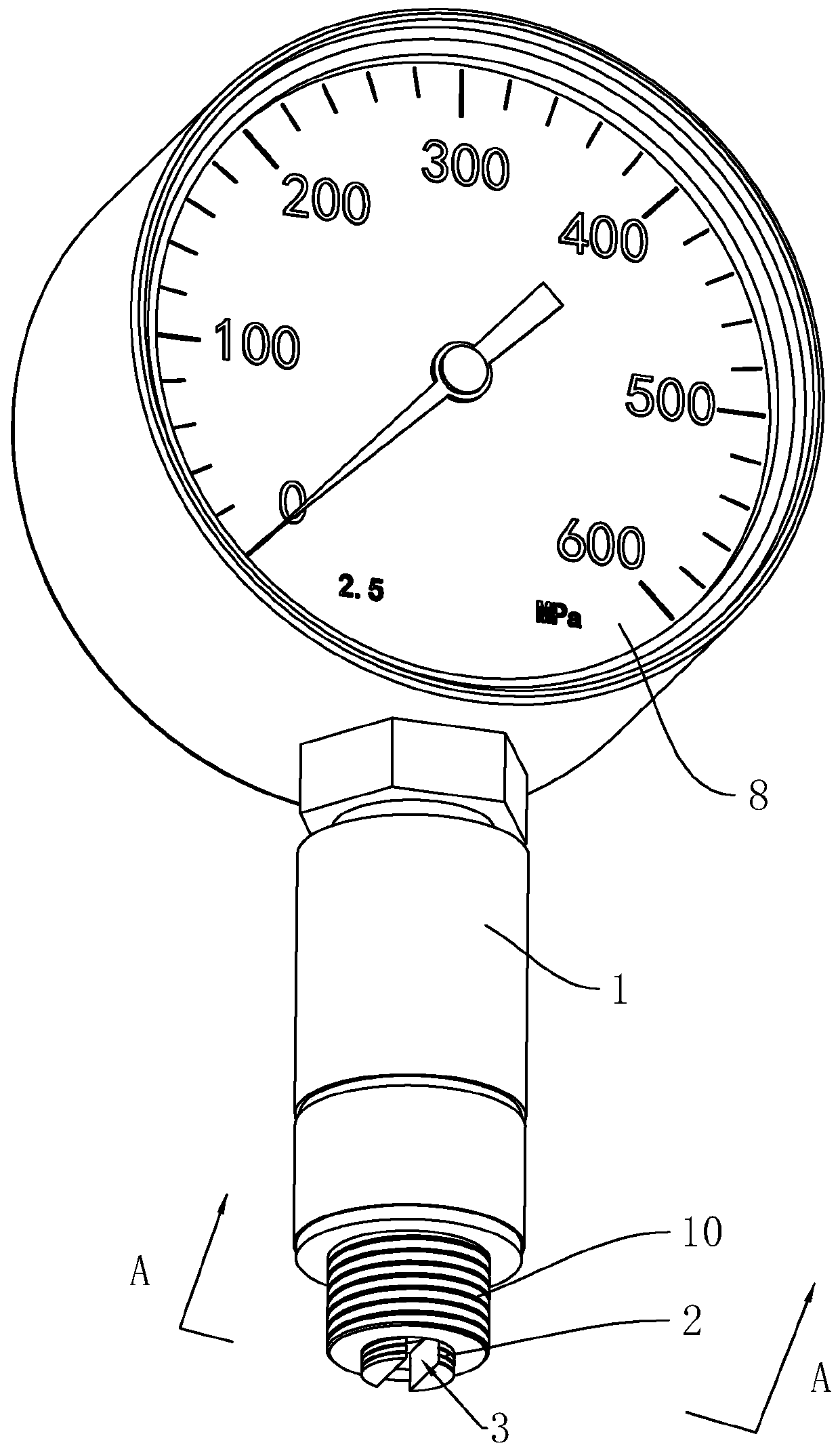

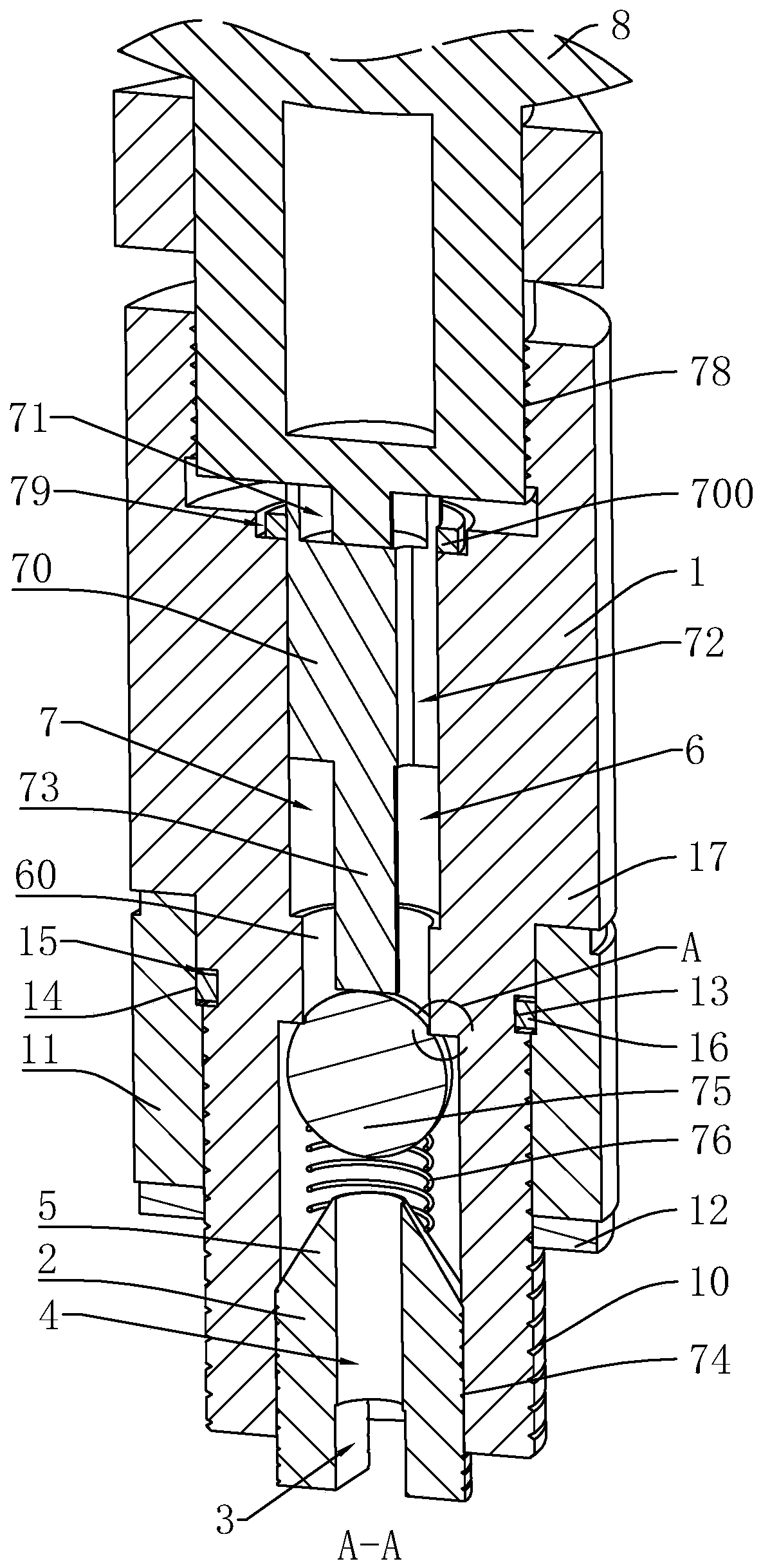

[0043] refer to figure 1 with figure 2 , an adjustable self-closing pressure gauge valve, which includes a cylinder 1, the outer wall of the cylinder 1 is provided with an external thread 10 screwed into the fuel tank, and the end of the cylinder 1 close to the fuel tank is threaded with a thimble 2, the cylinder 1 The end close to the fuel tank is threadedly connected with a thimble 2, the end of the thimble 2 away from the oil inlet 3 is provided with a tip 5, the end of the thimble 2 away from the tip 5 extends out of the cylinder 1, and the end of the thimble 2 protruding out of the cylinder 1 is provided with a The oil inlet 3 communicated with the oil tank, the thimble 2 is provided with a channel 4 communicated with the oil inlet 3 , and the barrel 1 is provided with a flow channel 6 communicated with the channel 4 .

[0044] refer to figure 2 , the tip 5 is sleeved with a self-closing component 7 for closing the flow channel 6, the self-closing component 7 slides i...

Embodiment 2

[0055] An adjustable self-closing pressure gauge with 8 valves, refer to Figure 4 with Figure 5 , based on Embodiment 1, the difference between this embodiment and Embodiment 1 is that the cylinder body 1 includes a fixed cylinder 18 connected to the pressure gauge 8 and a connecting cylinder 19 screwed to the fuel tank, and the fixed cylinder 18 is close to the connecting cylinder 19 One side is provided with a connecting ring groove 100, and the side of the connecting cylinder 19 close to the fixed cylinder 18 is provided with a ring piece 101 screwed into the connecting ring groove 100; it is convenient to connect the connecting cylinder 19 and the fixed cylinder 18.

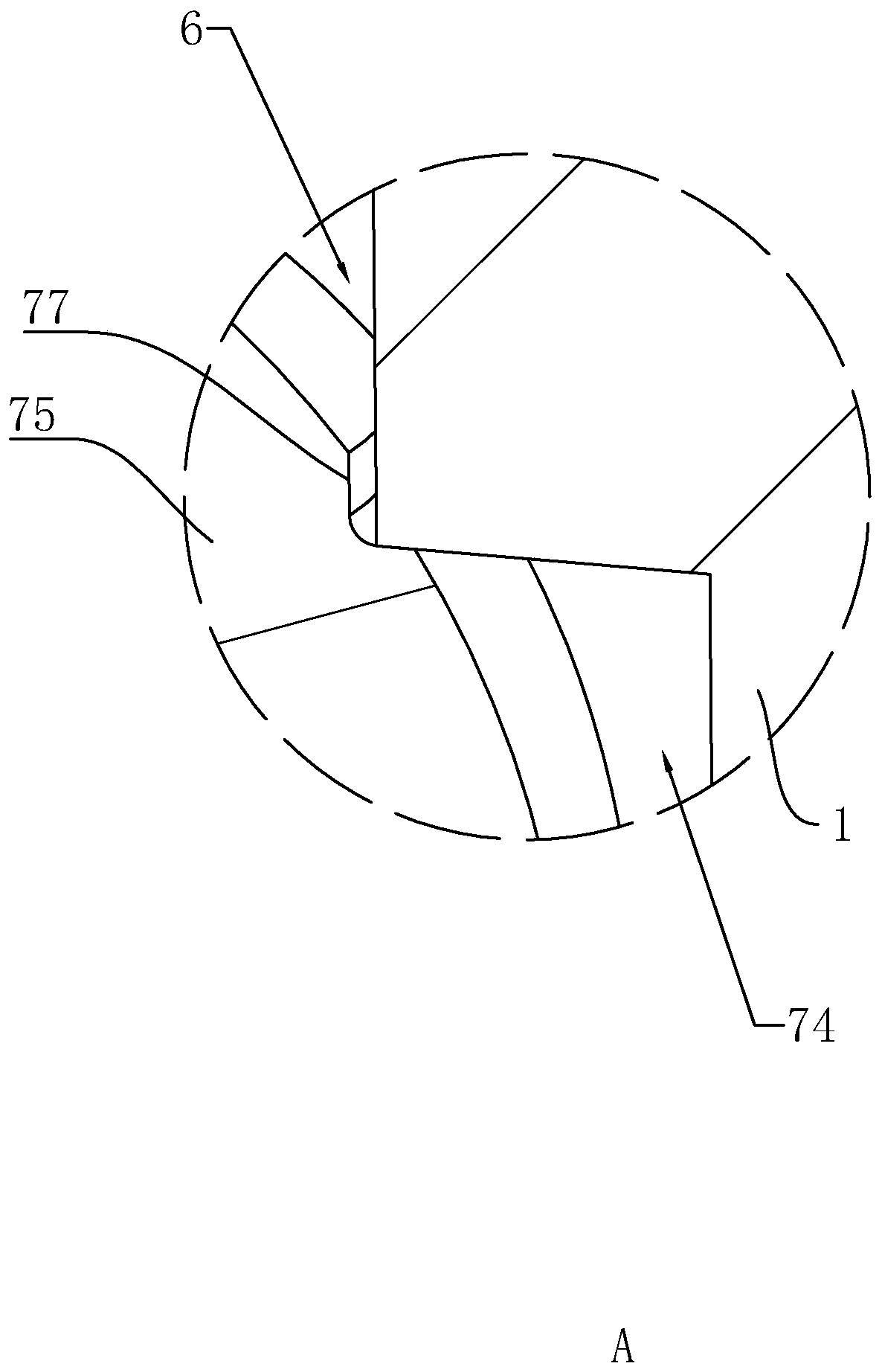

[0056] refer to Figure 5 with Image 6 , in the long-term use of the opening and closing ball 75, when the interference rod 73 squeezes the opening and closing ball 75, the opening and closing ball 75 is easy to rotate, and the junction corner between the annular groove 74 and the flow channel 6 is easy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com