Combined gearbox

A gearbox and combined technology, applied in the field of gearboxes, can solve the problems of consumption, slow driving speed, complicated installation, etc., and achieve the effect of reducing the overall volume, reducing the consumption of materials, and changing the overall area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

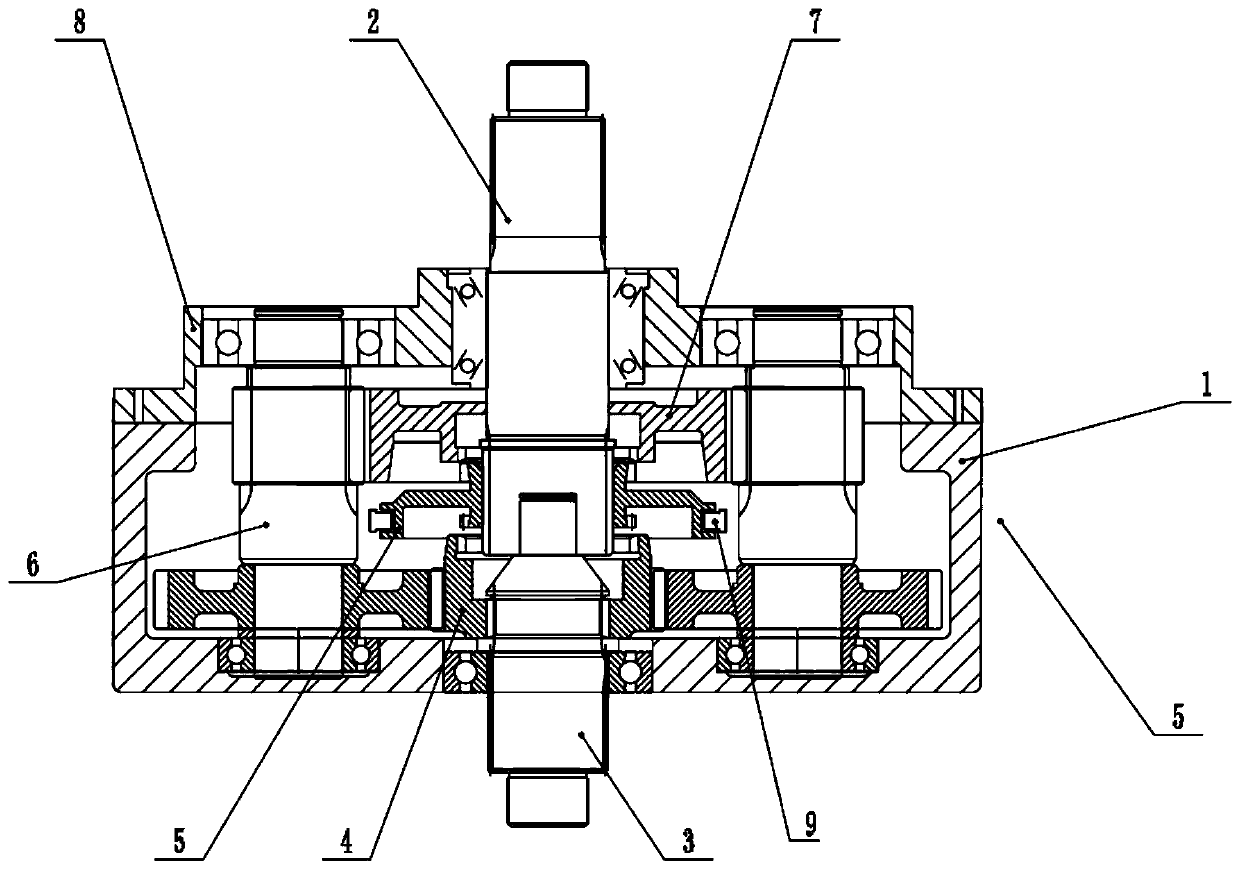

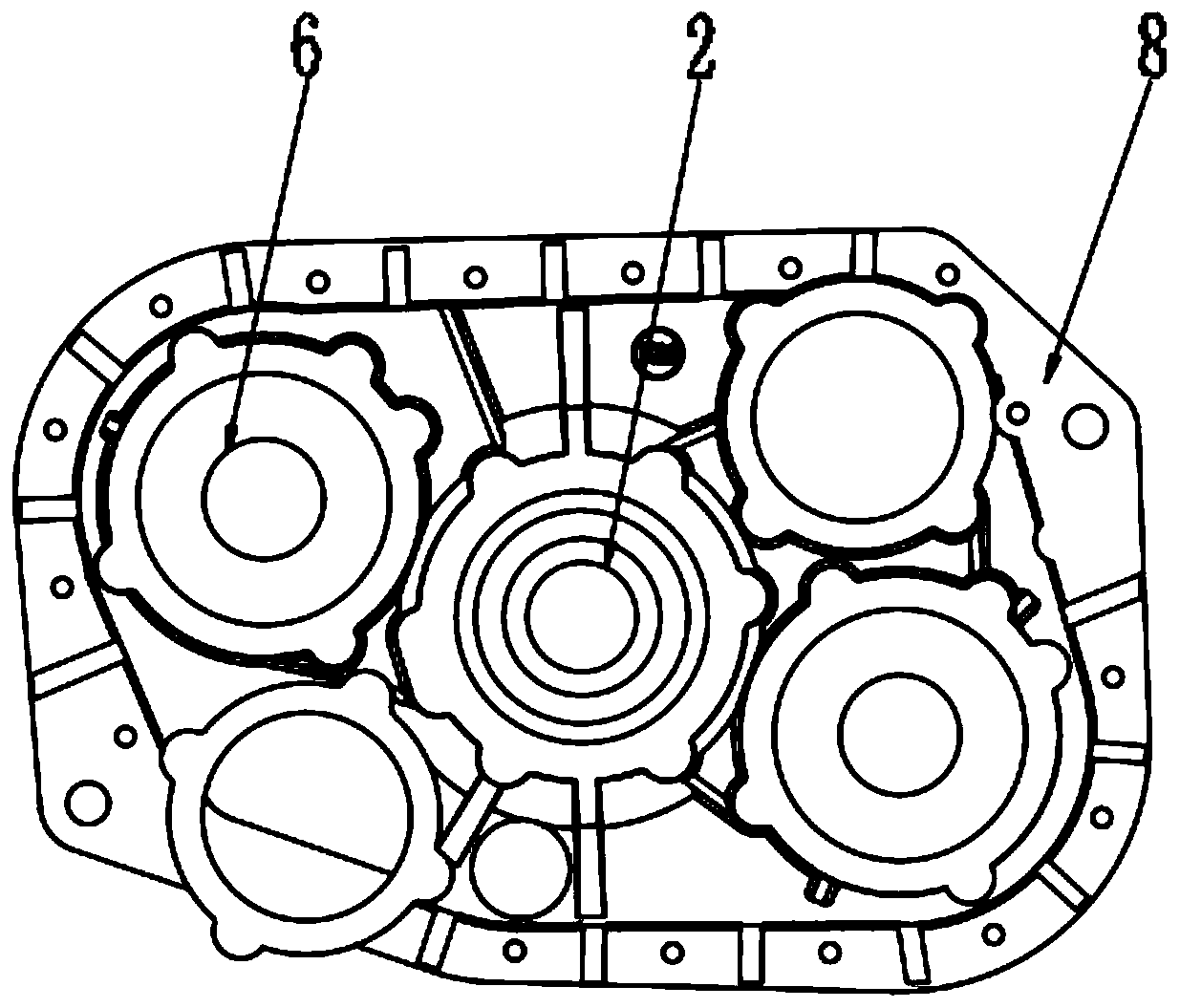

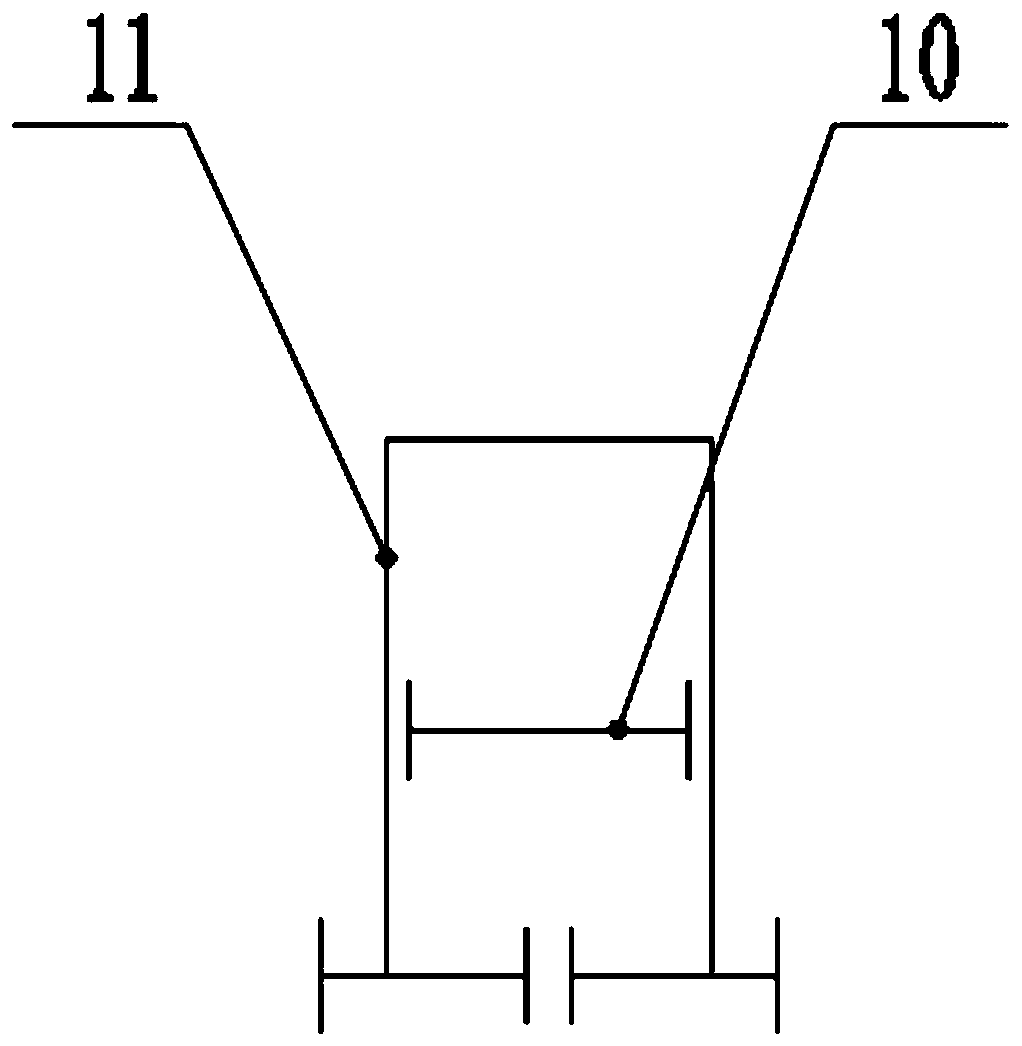

[0017] see Figure 1-3 , a combined gearbox, including a first box body 1, a welded shaft assembly 6 runs through the left and right sides of the first box body 1, an output shaft 2 is connected to the center of the top of the first box body 1, and the output shaft 2 The bottom speed gear 7 is connected between the outer surface of the outer surface and the two welded shaft assemblies 6, the top of the first case 1 is connected with the second case 8, the center of the bottom of the first case 1 is connected with the input shaft 3, and the input The top of the shaft 3 is clamped with the bottom of the output shaft 2, the outer surface of the input shaft 3 is sleeved with a high-speed gear 4, the outer surface of the output shaft 2 is sleeved with a sliding sleeve 5, and the outer surface of the sliding sleeve 5 is clamped with a fork 9. The fork 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com