Protective shed of construction site distribution box

A technology for construction sites and distribution boxes, applied in earthquake-proof, special buildings, small buildings, etc., can solve problems such as high cost, damage to distribution boxes, safety accidents, etc., achieve good rigidity and stability, and eliminate shocks. The effect of energy, good anti-collision ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

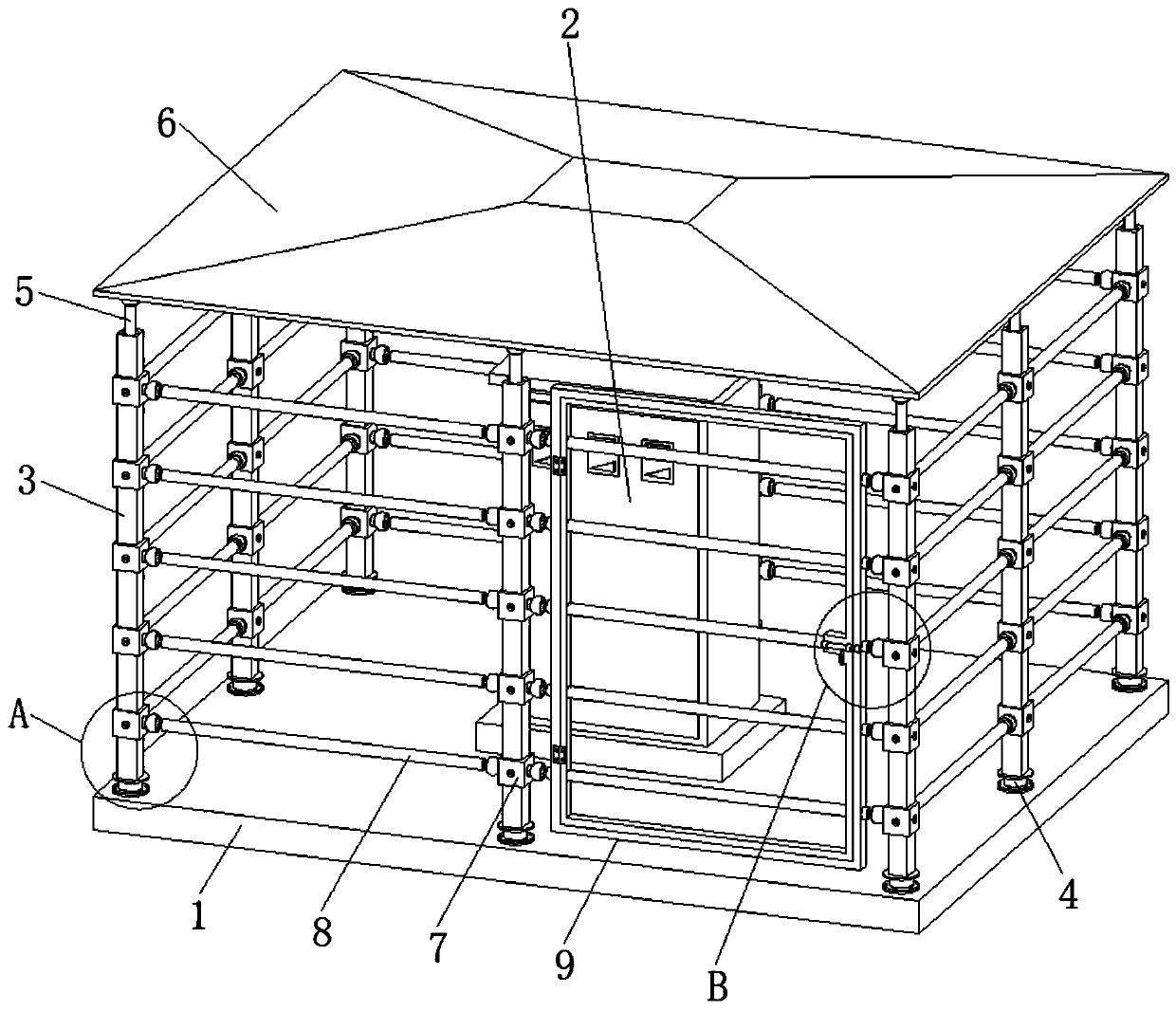

[0036] like Figure 1-Figure 8 As shown, a first embodiment of the protection shed for the distribution box at the construction site of the present invention is provided. The upper end of the foundation 2 is located on the peripheral side of the distribution box 1, and the bottom end of the column rod 3 is fixed with a rubber support 4, wherein the rubber support 4 includes a rubber column 401, and a ring-shaped steel plate 402 layered and fixed in the rubber column 401 , the upper connecting steel plate 403 fixed on the upper end of the rubber column 401 and the lower connecting steel plate 404 fixed on the lower end of the rubber column 401, the upper connecting steel plate 403 is fixed on the lower end of the column rod 3, and the lower connecting steel plate 404 is connected with a pre-embedded steel foot 10 by bolts , the pre-embedded steel feet 10 can be used for one-time construction without recycling, which is convenient for the disassembly and assembly of the column r...

Embodiment 2

[0046] like Figure 9 As shown, a second embodiment of the protection shed for the distribution box at the construction site of the present invention is provided. The difference from the first embodiment is that the energy dissipation structure in the buffer hole 301 is an energy dissipation spring 12, and the energy dissipation The spring 12 is set between the buffer rod 5 and the inner wall of the buffer hole 301, the energy dissipation spring 12 provides the upward support force of the buffer rod 5, and the inner wall of the upper end of the buffer hole 301 is fixed with a limit ring, which limits the maximum upward stroke of the buffer rod 5 , The energy-dissipating spring 12 can also play the role of energy-dissipating and shock-absorbing, and provides impact protection for the ceiling 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com