Diaphragm gas pressure tank with gas compensation device

A gas compensation and air pressure tank technology, applied in water supply installations, water supply pool configuration, construction, etc., can solve problems such as difficult water pressure, troublesome manual inspection, air leakage, etc., and achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

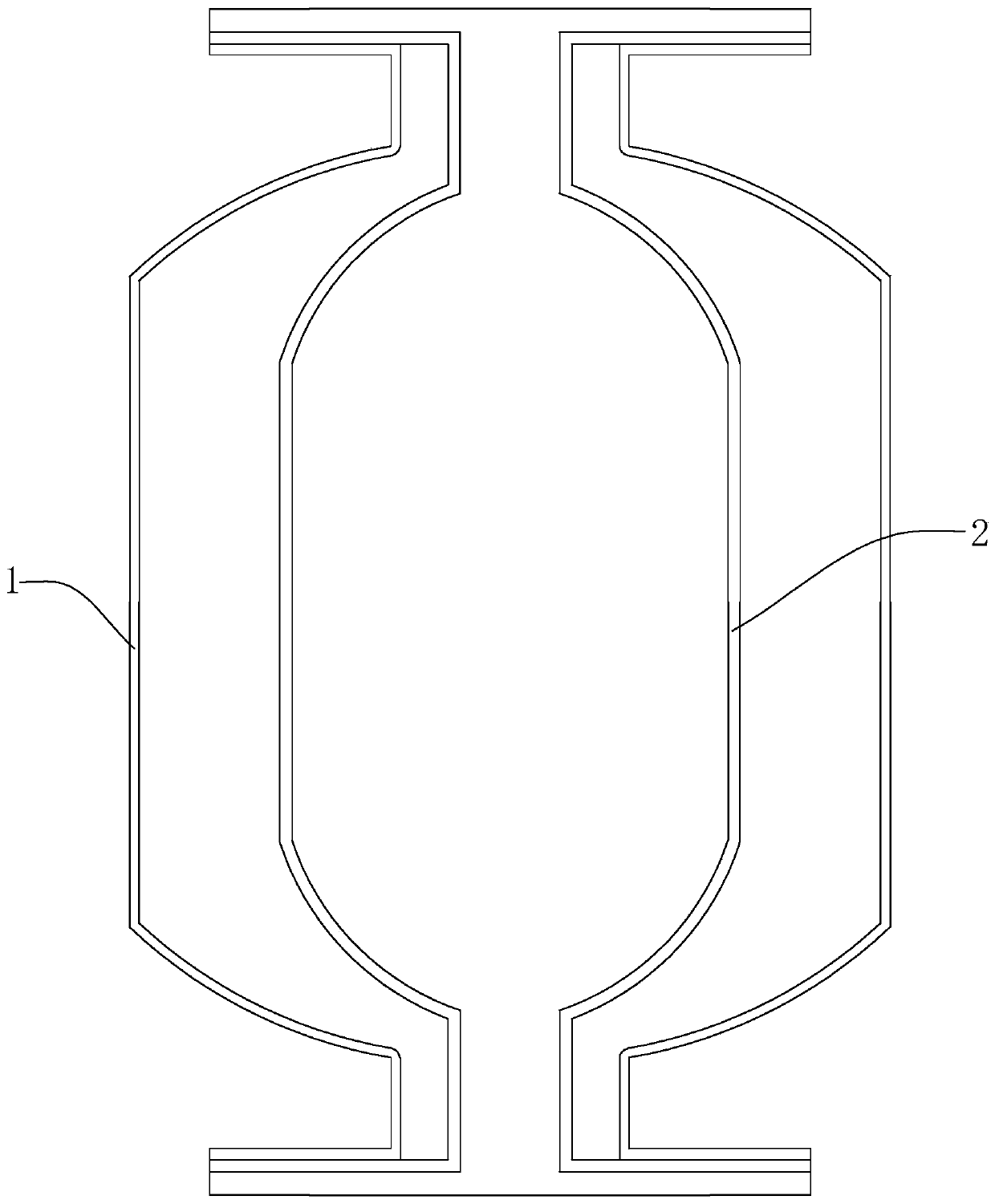

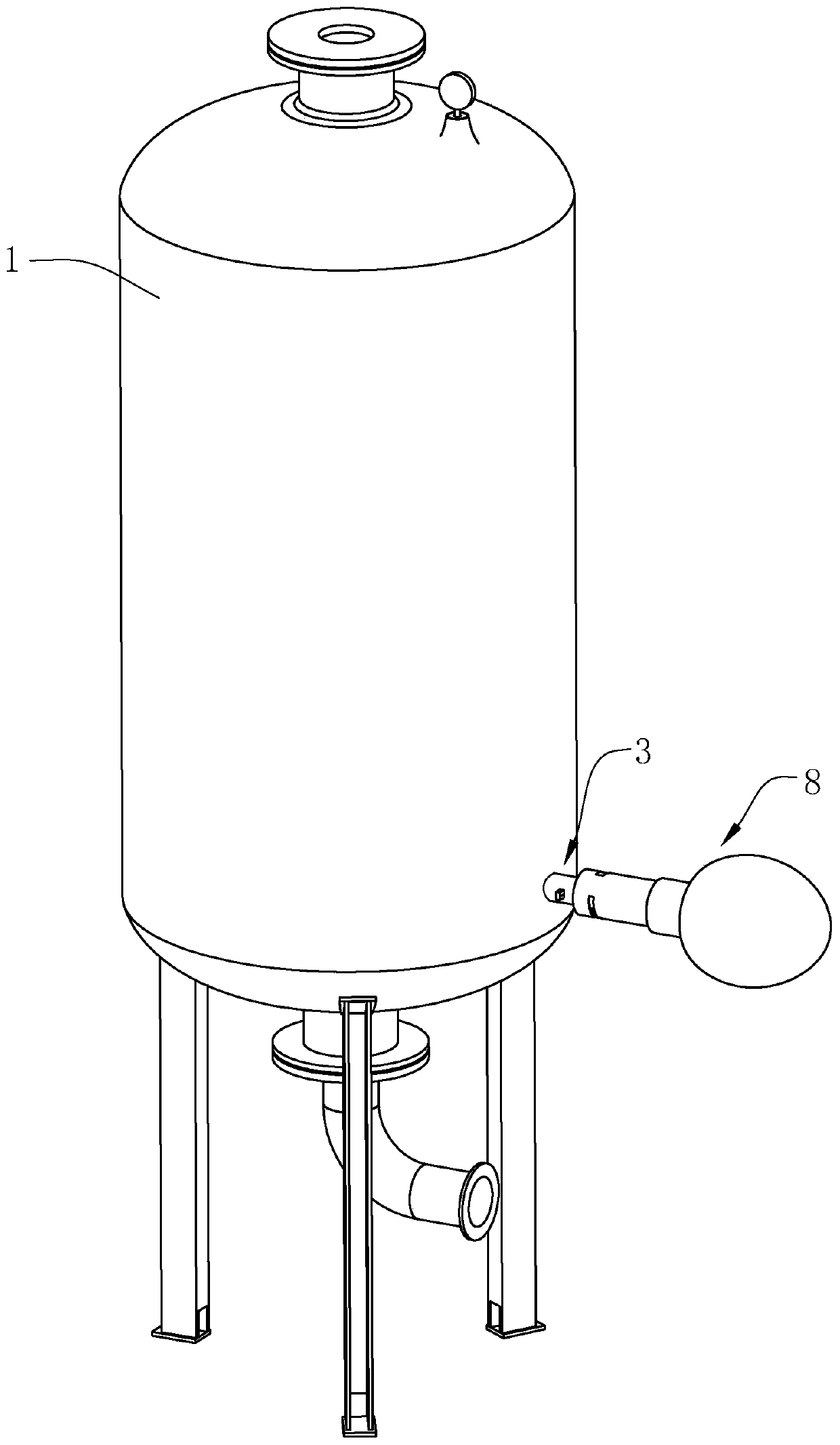

[0036] Such as figure 2 As shown, a diaphragm pressure tank with a gas compensation device includes a tank body 1 and an inner tank 2, the tank body 1 is placed vertically, the two ends of the inner tank 2 protrude from the tank body 1, and the tank body 1 and the inner tank Both ends of 2 are fixedly connected by flange structure, the upper end of the tank body 1 is connected with the water pump, and the lower end is connected with the water pipe, that is, the water pipe communicates with the inner tank 2, and an air supply valve 3 is arranged on the tank body 1; After the air supply valve 3 inflates the tank body 1, water is injected into the inner tank 2 through the water pump. When the water pump is at rest, if the water pressure in the water pipe changes, the inner tank 2 is squeezed, contracted or expanded to balance the pressure in the water pipe. Ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com