Assembly type frame beam slope protection construction method

A technology for slope protection and construction method, applied in chemical instruments and methods, botanical equipment and methods, excavation, etc., can solve problems such as poor slope protection effect, soil erosion, and poor plant root stability, and achieve enhanced protection. effect, increase protection, increase the effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

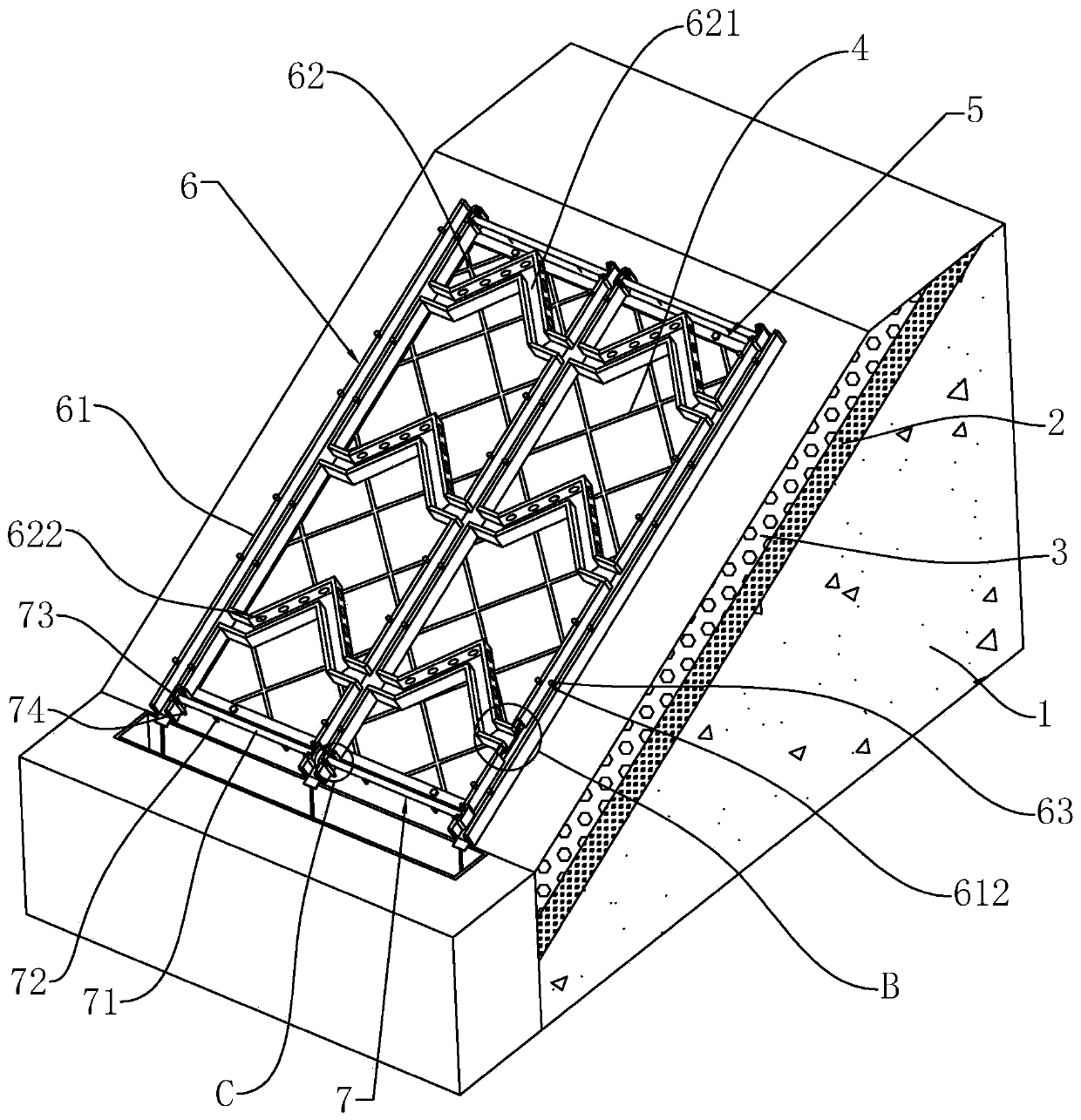

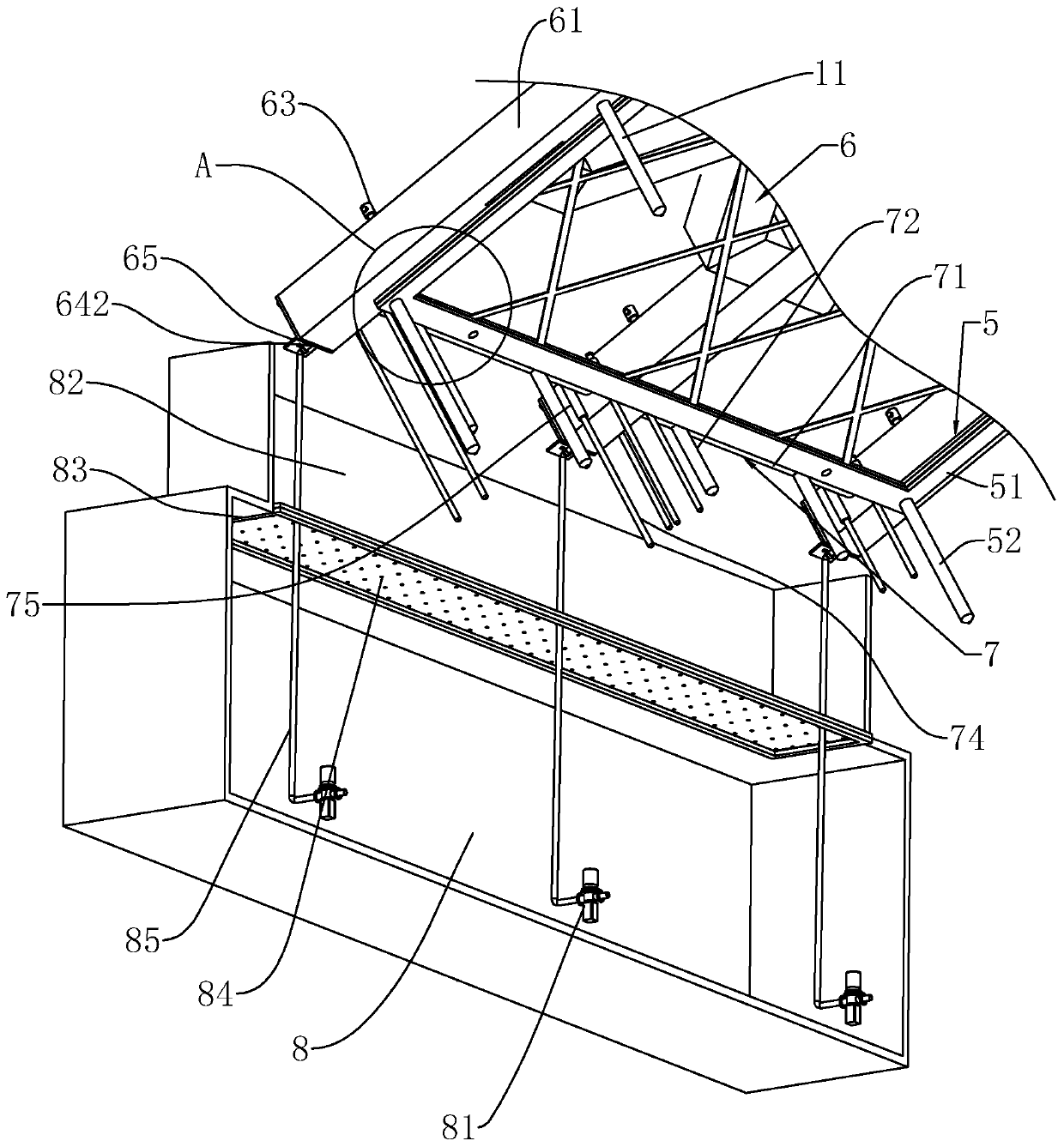

[0048] refer to Figure 1-Figure 3 , is a kind of fabricated frame beam slope protection construction method disclosed by the present invention, comprising the following construction steps:

[0049] S1. Remove sundries, floating soil and loose rock blocks on the slope surface of side slope 1, and then perform leveling and compaction operations to reinforce the slope surface.

[0050] S2. Laying the waste residue layer 2 and the growth substrate layer 3 sequentially on the slope, and then laying the reinforcement mesh 4 on the growth substrate layer 3, and the reinforcement mesh 4 is fixed on the side slope 1 through the fixing member 5.

[0051] Construction of S3, frame beam 6:

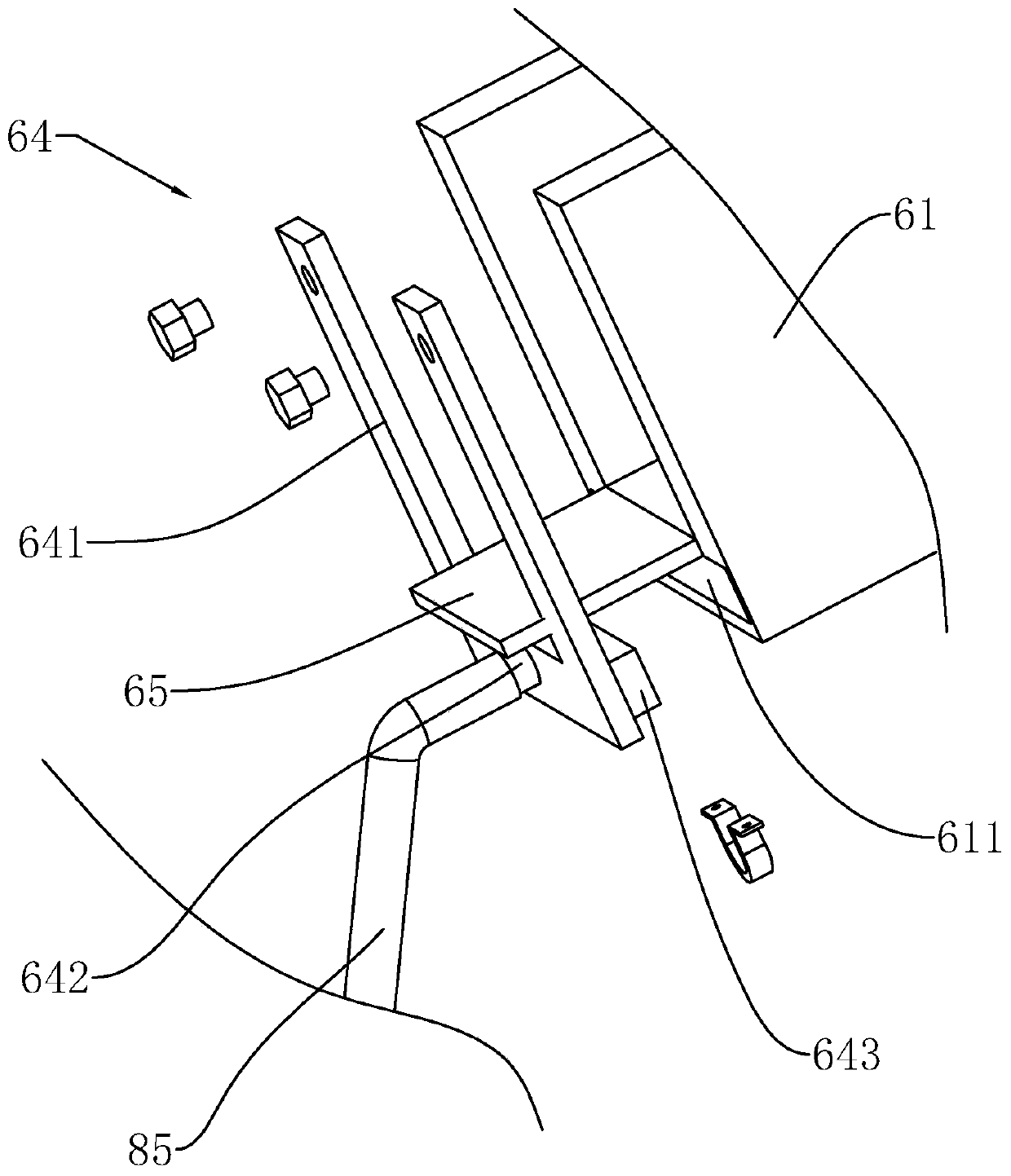

[0052] Wherein, the frame beam 6 includes a water guide part 61 and a water guide part 62 . A plurality of water guiding parts 61 are arranged at intervals along the length direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com