Construction method for vertical main pipe protection of hot spring well in foundation pit

A construction method and hot spring technology, which are applied in infrastructure engineering, excavation, drinking water installations, etc., can solve the problems of difficulty in normal operation and production of hot spring well standpipes, difficulty in normal construction, and easy impact on construction progress, etc. Risk of damage, increased rigidity, the effect of fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

[0031] Project location: Zhengxiang Guili Xiangyuan, Fuzhou City, Fujian Province; construction project: three hot spring wells in the basement; two of the three hot spring wells are high-temperature wells, and one is low-temperature well. The specific protection construction steps are as follows:

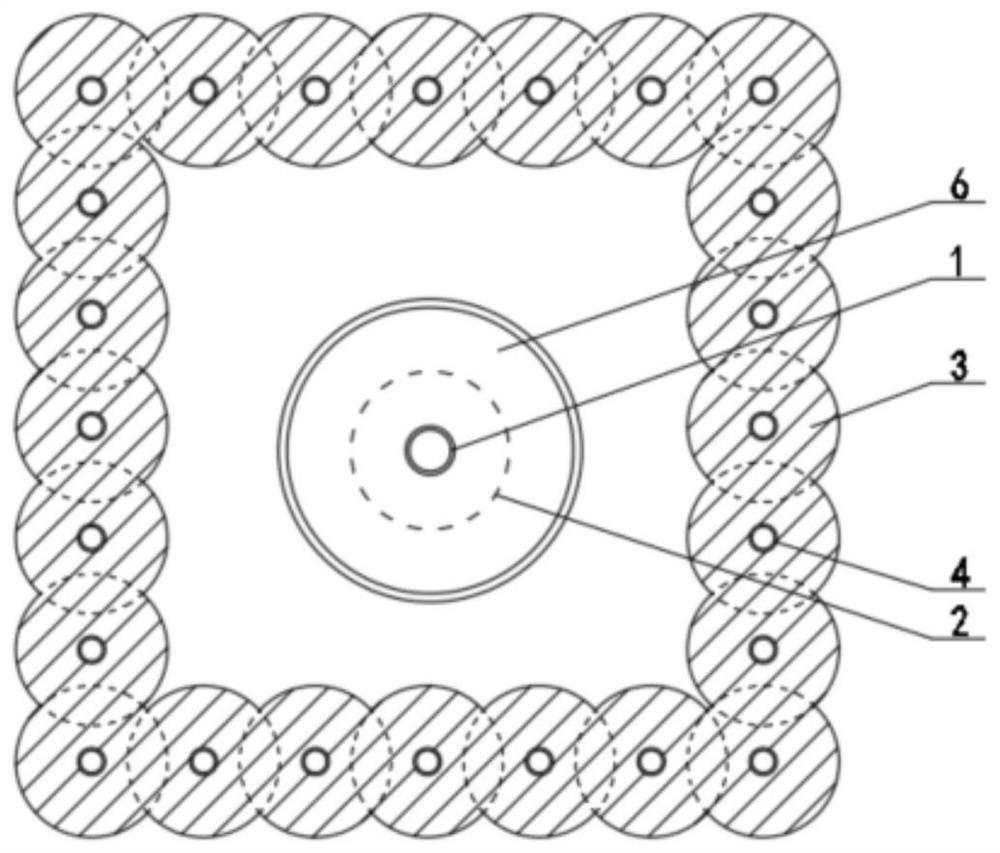

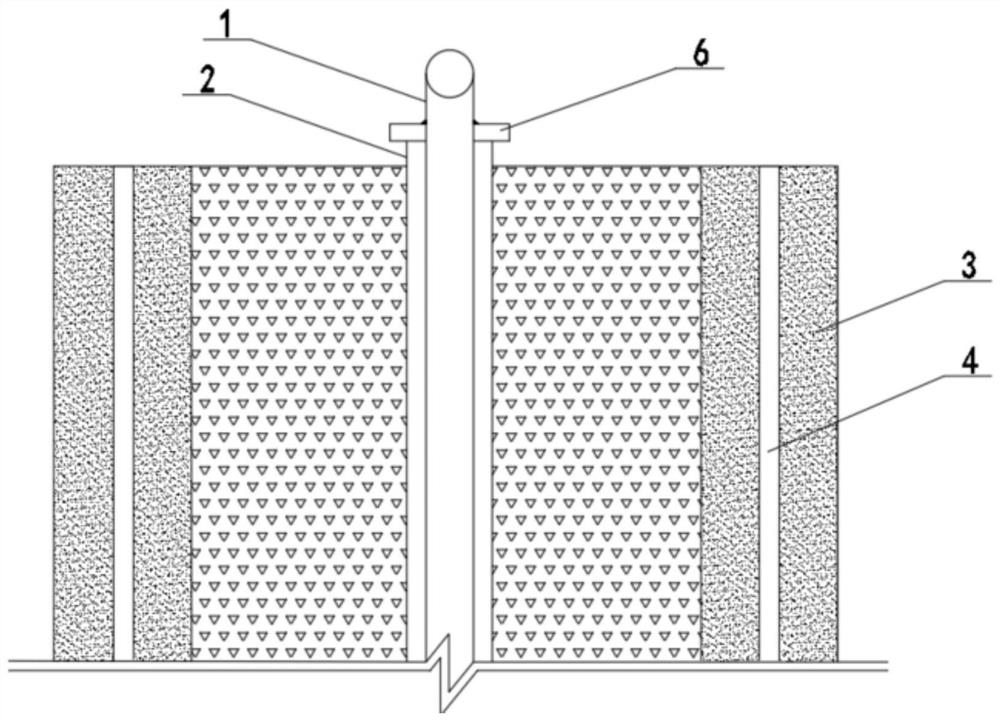

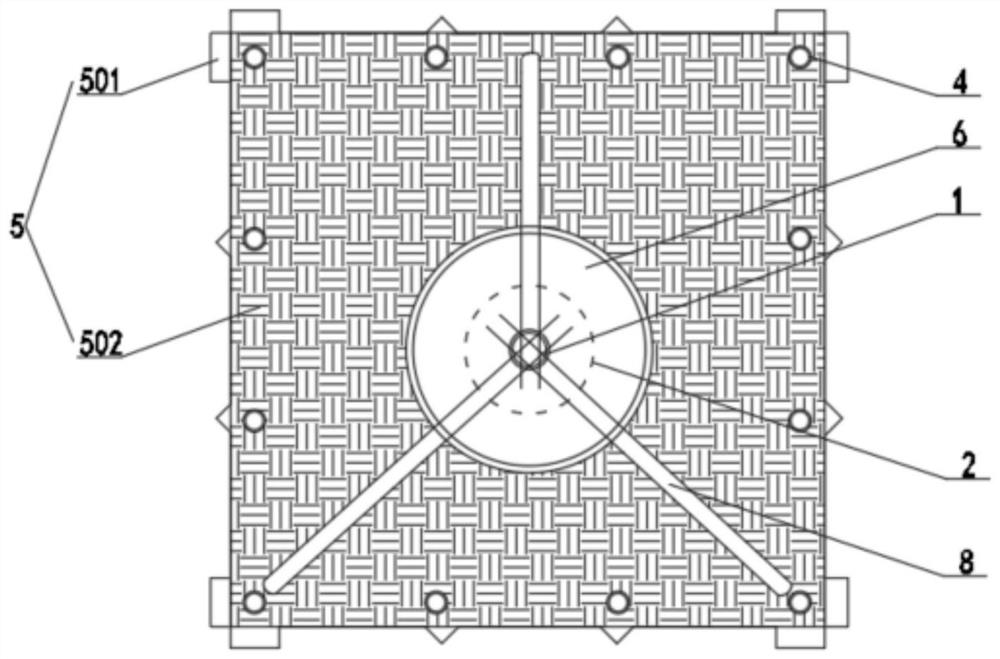

[0032] 1) if Figure 1-2 As shown, with the casing 2 of the hot spring well vertical pipe 1 as the center, a circle of cement mixing piles 3 is arranged along the periphery of the hot spring well vertical pipe 1, and the middle sand layer is used as the embedded end of the cement stirring pile 3, and the cement stirring pile The center of 3 is respectively inserted with the metal pipe 4 (in this embodiment, the metal pipe 4 adopts DN80 seamless steel pipe) whose l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com