Concrete pouring device for cast-in-place ballastless track bed construction

A ballast bed and concrete technology, which is applied in the field of pouring devices for railway engineering construction, can solve the problems of low construction precision and increased construction cost, achieve good shock absorption effect, improve construction precision, and reduce construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

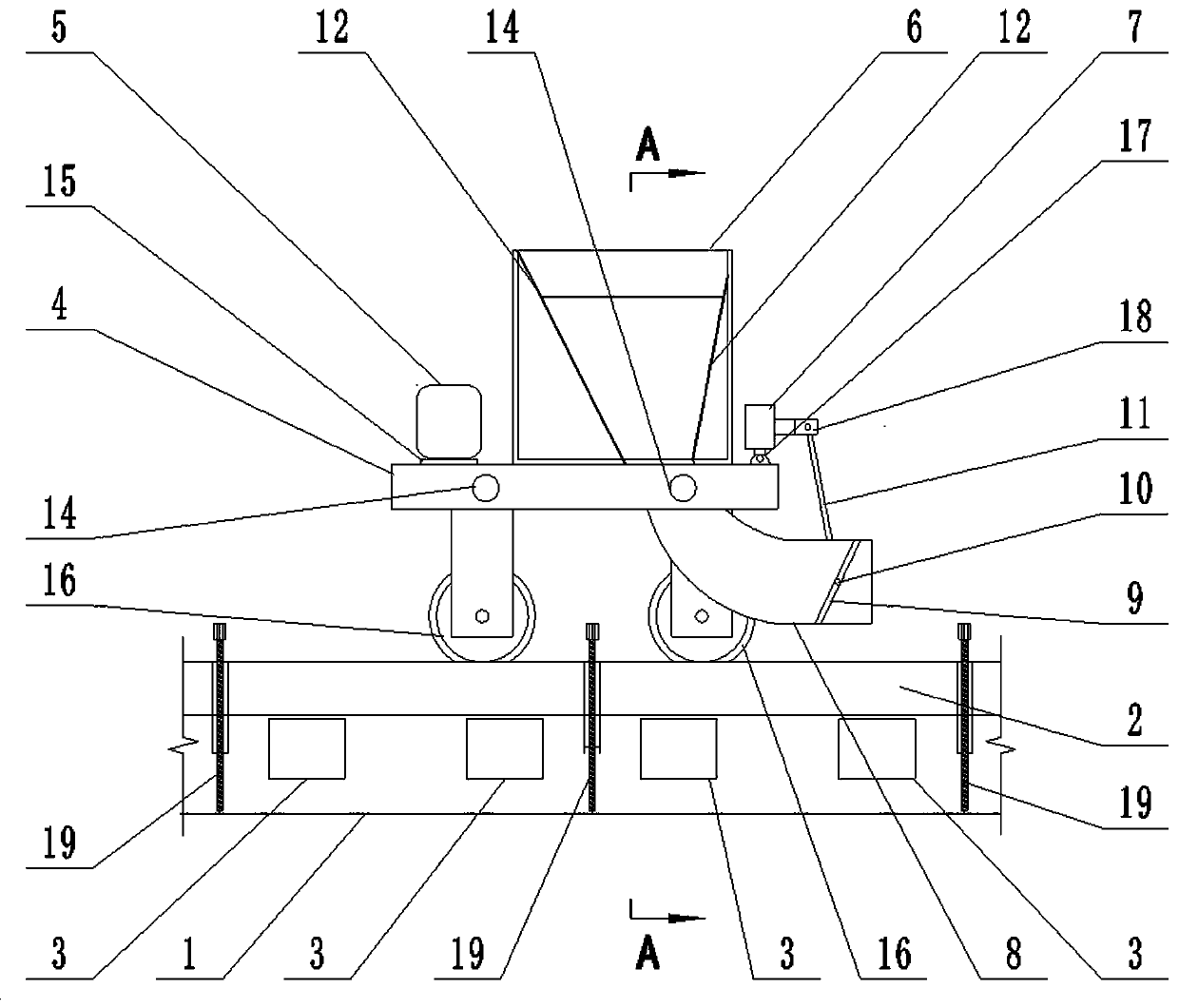

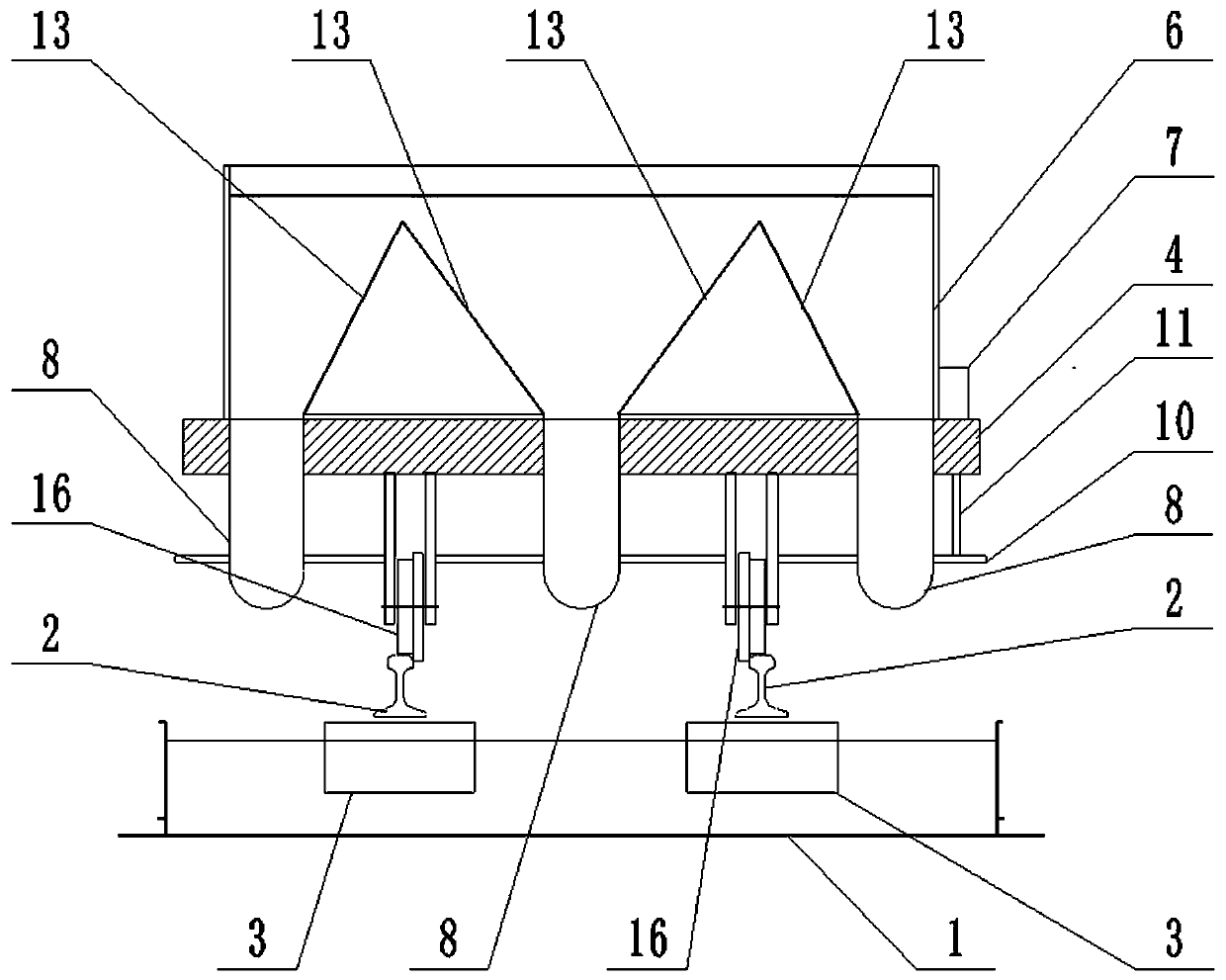

[0027] A concrete pouring device for cast-in-place ballastless track bed construction, comprising a base surface 1 and a rail row erected on the base surface 1, the rail row including two tool rails 2 and two rows of short sleepers 3; and a wireless remote control device and an electric flatbed car that walks on two tool rails 2 along the left and right direction, the upper surface of the frame 4 of the electric flatbed cart is provided with a generator 5, a hopper 6 and an electric push rod 7 facing rightward in the direction of the push rod, and the electric push rod The bottom of 7 is hinged on vehicle frame 4; the output end of generator 5 is respectively connected with the power end of the drive motor of electric flatbed car, the power end of electric push rod 7;

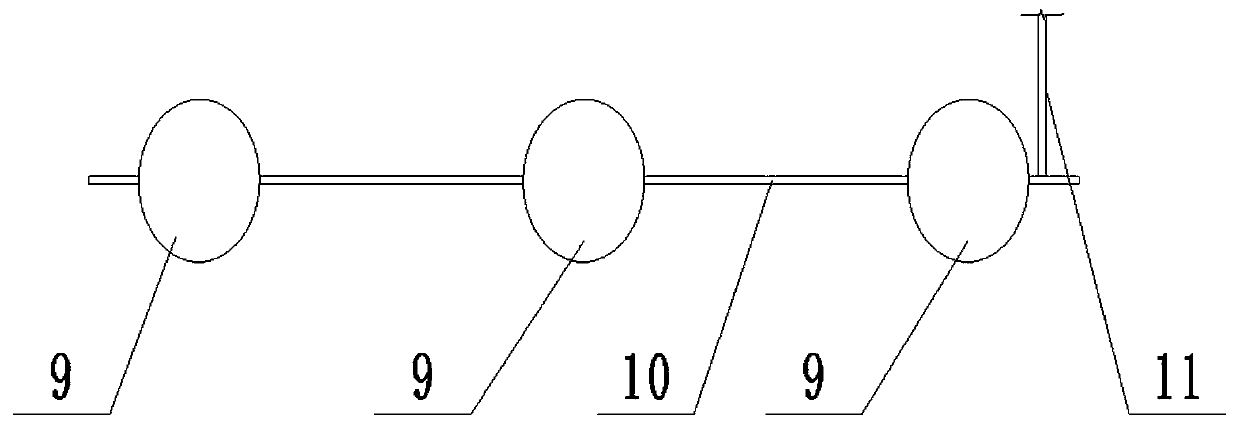

[0028] The bottom of the hopper 6 is provided with three blanking elbows 8 which are connected with it and distributed parallel to the front and back. The material elbow 8 and the two rows of short sleepers 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com