Tramcar rail fastener

A technology for track fasteners and trams, which is applied in the direction of tracks, roads, fixed rails, etc., can solve the problems of poor insulation performance, poor height adjustment or distance adjustment ability, complex structure, etc., and achieve simple structure and high height adjustment ability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

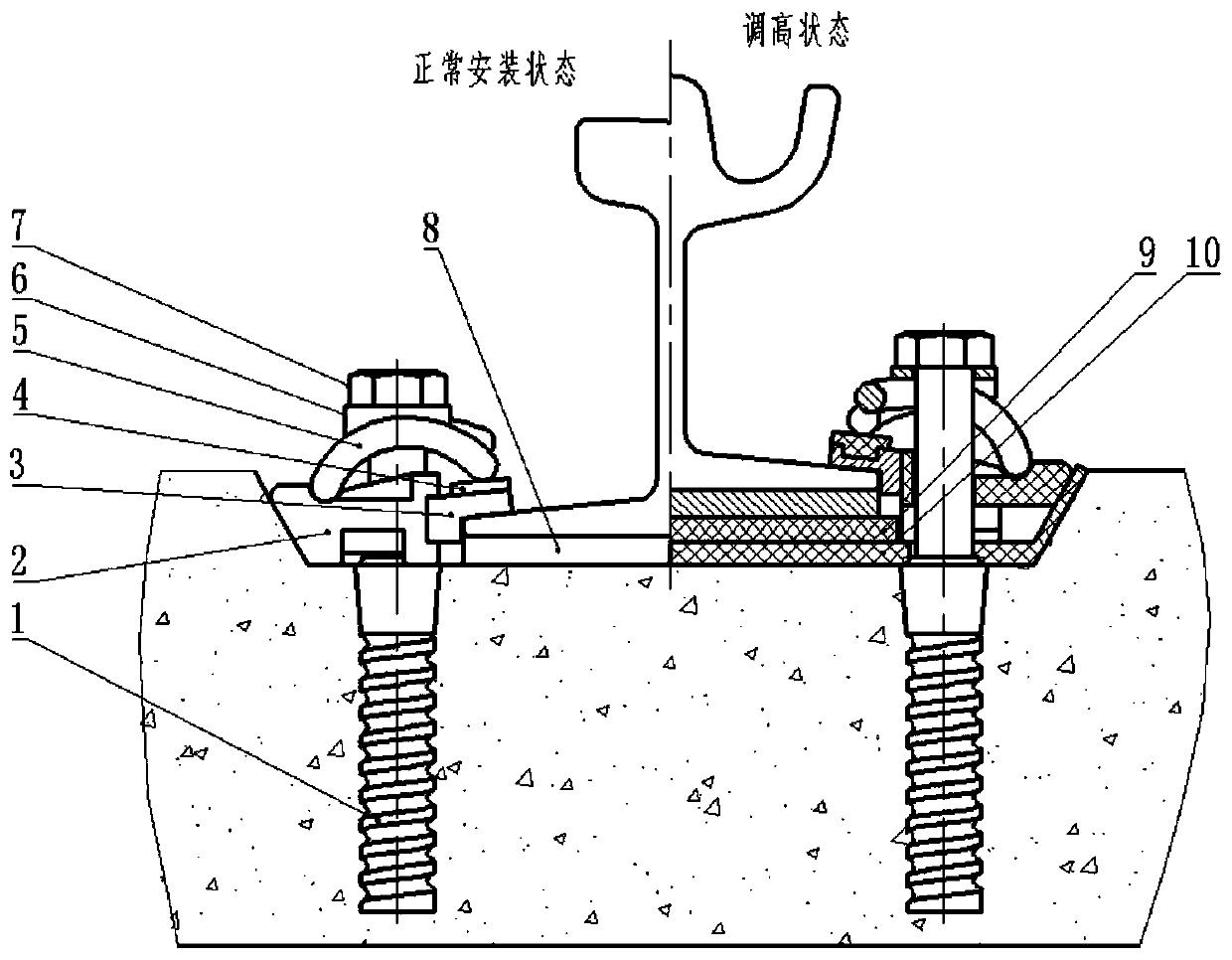

[0027] The tramway fastener of the present invention is a non-separate type fastener with shoulder elasticity, such as figure 1 As shown, including: embedded sleeve 1, gauge baffle plate 2, gauge block 3, plastic pad 4, elastic bar 5, square gasket 6, spiral spike 7, rubber pad 8, under-rail height adjustment pad 9. Adjust the backing plate 10 as a whole.

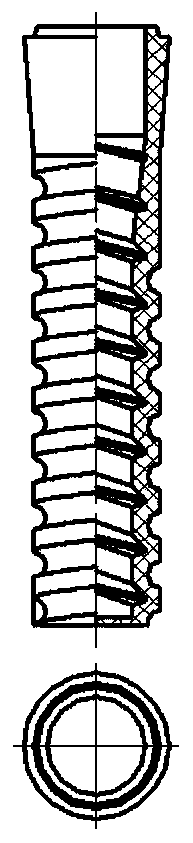

[0028] Such as figure 2 As shown, the embedded casing 1: the material is glass fiber reinforced polyamide 66, which is embedded in the concrete sleeper, and the casing has internal threads to cooperate with the spiral spike 7.

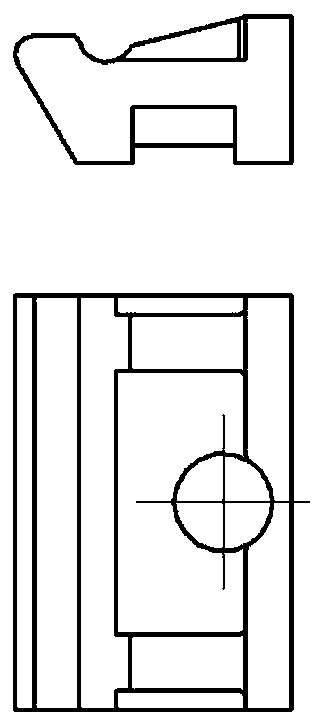

[0029] Such as image 3 As shown, the gauge baffle 2: the material is glass fiber reinforced polyamide 66, and the sides of the gauge baffle are respectively in contact with the sleeper shoulder and the gauge block 3, which are used to ensure the position of the rail and transmit the lateral force of the rail to the sleeper . The gauge baffle is provided with a position for laying the elastic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com