A kind of production method of wear-resistant steel plate

A technology of wear-resistant steel plates and production methods, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of reducing the internal stress of wear-resistant steel plates, cannot realize direct loading and heating of hot billets, and is unfavorable for energy saving and emission reduction, and achieves the elimination of tissue Stress and thermal stress, reducing the natural cracking tendency of the steel plate, and satisfying the effect of large input energy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

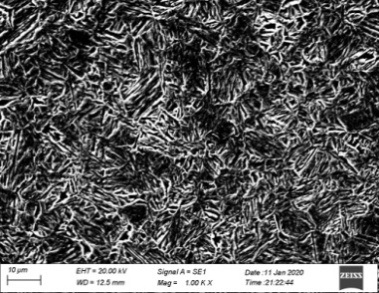

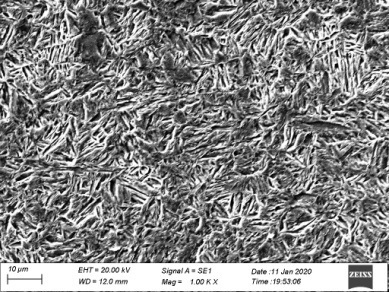

Image

Examples

Embodiment 1

[0058] Production of NM400 wear-resistant steel plates, the process is as follows:

[0059] The chemical composition mass of steel is: C = 0.20, Si = 1.05, Mn = 1.33, P = 0.015, S = 0.003, Ti = 0.078, B = 0.0020, Ni = 0.18, the margin is FE and inevitable impurities.

[0060] Production process route: Iron water dethinated → converter smelting → refining → vacuum treatment → Continuous casting → rolling → quenching → tempering.

[0061] (1) Iron water desulfurization: Make sure the slag is clean before the iron water is converted; the iron sulfur content S = 0.009% after treatment;

[0062] (2) Converter smelting: end point control goal: c = 0.10%, P = 0.010%, s = 0.001%; ensure that CT coordinated steel, T: 1563 ° C, end point o: 664ppm; out of steel time 5 min; And the skateboard joint slag, slag thickness 40mm; the steel bag is added to the steel bag in the steel bag, metal MN1600KG, nickel plate 300kg and lime 500kg; the metal MN should start to add, to 1 / 4 After 2 / 3 or so. ...

Embodiment 2

[0089] Production NM450 wear-resistant steel plate, the process is as follows:

[0090] The chemical composition mass of steel is: C = 0.20, Si = 1.05, Mn = 1.33, P = 0.015, S = 0.003, Ti = 0.078, B = 0.0020, Ni = 0.18, the margin is FE and inevitable impurities.

[0091] Production process route: Iron water dethinated → converter smelting → refining → vacuum treatment → Continuous casting → rolling → quenching → tempering.

[0092] (1) Iron water desulfurization: Make sure the slag is clean before the iron water is converted; the iron sulfur content S = 0.009% after treatment;

[0093] (2) Converter smelting: end point control goal: c = 0.10%, P = 0.010%, s = 0.001%; ensure that CT coordinated steel, T: 1563 ° C, end point o: 664ppm; out of steel time 5 min; And the skateboard joint slag, slag thickness 40mm; the steel bag is added to the steel bag in the steel bag, metal MN1600KG, nickel plate 300kg and lime 500kg; the metal MN should start to add, to 1 / 4 After 2 / 3 or so.

[0...

Embodiment 3

[0121] Production of NM500 wear-resistant steel plates, the process is as follows:

[0122] The chemical composition mass of steel is: C = 0.20, Si = 1.05, Mn = 1.33, P = 0.015, S = 0.003, Ti = 0.078, B = 0.0020, Ni = 0.18, the margin is FE and inevitable impurities.

[0123] Production process route: Iron water dethinated → converter smelting → refining → vacuum treatment → Continuous casting → rolling → quenching → tempering.

[0124] (1) Iron water desulfurization: Improving the slag before the iron water into the converter; after the treatment, the iron sulfur content S = 0.009%.

[0125] (2) Converter smelting: end point control goal: c = 0.10%, P = 0.010%, s = 0.001%; ensure that CT coordinated steel, T: 1563 ° C, end point o: 664ppm; out of steel time 5 min; And the skateboard joint slag, slag thickness 40mm; the steel bag is added to the steel bag in the steel bag, metal MN1600KG, nickel plate 300kg and lime 500kg; the metal MN should start to add, to 1 / 4 After 2 / 3 or so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com