A steam-cured cement-based material with high water absorption resistance and preparation method thereof

A cement-based material and water adsorption technology, applied in the field of building materials, can solve the problems of negative effects of mechanical properties and poor compatibility of cement-based materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of carrier D / EG for phase change composite materials

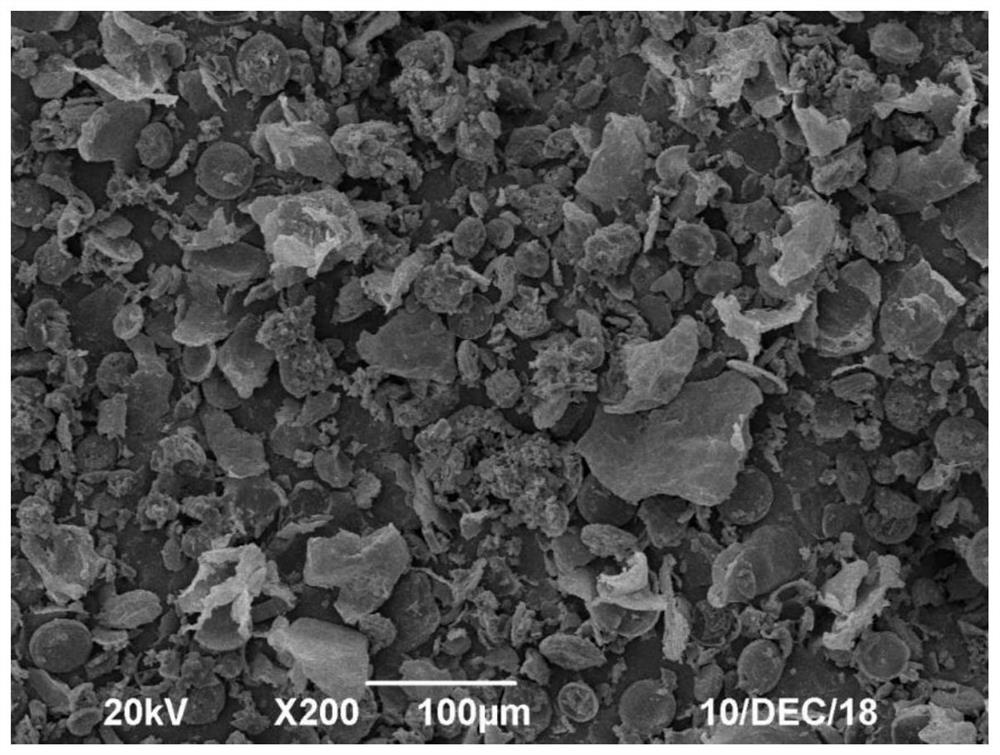

[0041] Add 1g of 200-mesh expandable graphite expanded at 900°C for 30s into 500ml of absolute ethanol for ultrasonic dispersion for 30 minutes, then add 31g of diatomite with a fineness of 120 mesh, and continue ultrasonic dispersion for 50 minutes, during which time a glass rod is also used for stirring , to obtain a new solution of D / EG mixture. The obtained new D / EG mixed solution was continuously stirred at 30°C and 1500 r / min for 60 min to obtain a D / EG mixed solution. The obtained mixed solution was cooled to room temperature after evaporating absolute ethanol at 100°C. The obtained moist solid powder D / EG was placed in an oven at 105°C and dried for 24 hours to obtain the carrier D / EG of gray powder phase change composite material. Depend on figure 1 It can be seen that diatomaceous earth and expanded graphite are evenly mixed.

[0042] 2. Preparation of phase change composite material D / E...

Embodiment 2

[0056] 1. Preparation of carrier D / EG for phase change composite materials

[0057] Add 1g of 200-mesh expandable graphite expanded at 900°C for 1min to 550ml of absolute ethanol for ultrasonic dispersion for 20min, then add 34.7g of diatomite with a fineness of 120mesh, and continue ultrasonic dispersion for 60min, during which glass rods are also used Stir to obtain a new mixed solution of D / EG. The obtained D / EG mixed solution was continuously stirred for 70 min at 30°C and 1300 r / min to obtain a D / EG mixed solution. The obtained mixed solution was cooled to room temperature after evaporating absolute ethanol at 100°C. The obtained moist solid powder D / EG was placed in an oven at 105°C and dried for 24 hours to obtain the carrier D / EG of gray powder phase change composite material.

[0058] 2. Preparation of phase change composite material D / EG / P

[0059] First, 220g of paraffin wax with a melting point of 58°C was gradually melted into a liquid at 90°C. Put 40g of D / EG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com