Printing/coating equipment

A technology of coating equipment and coating devices, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of reduced printing speed and accuracy, increased scrap rate, and uneven expansion and contraction, so as to reduce material loss and waste products rate, to eliminate the effect of coil expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

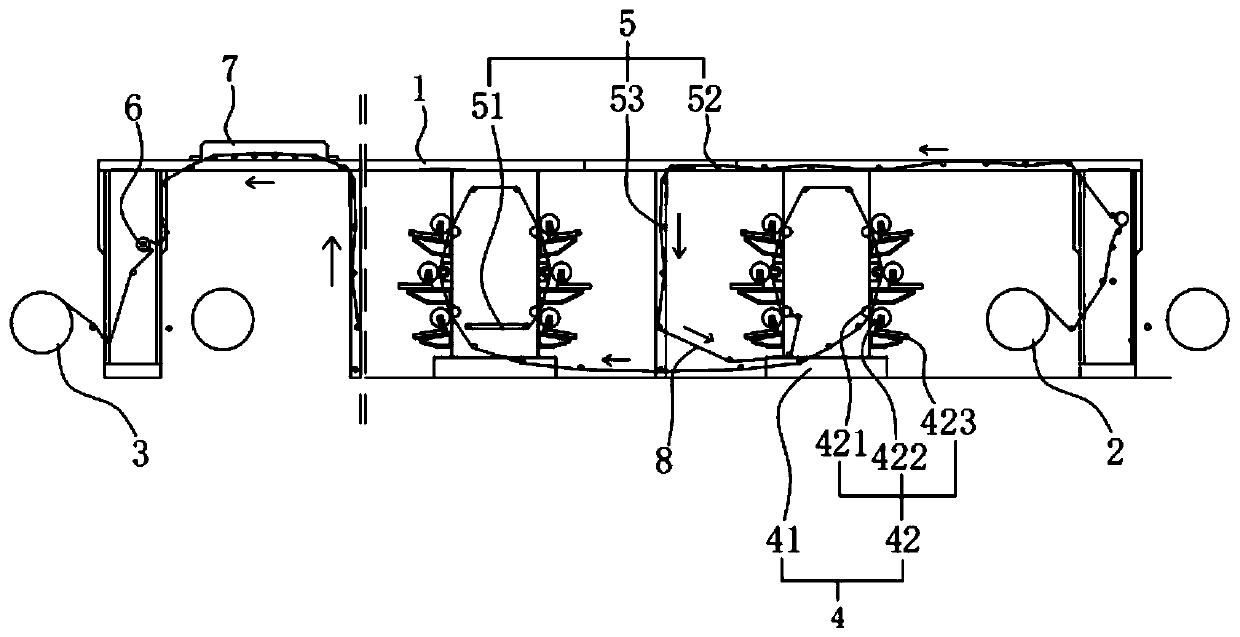

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings.

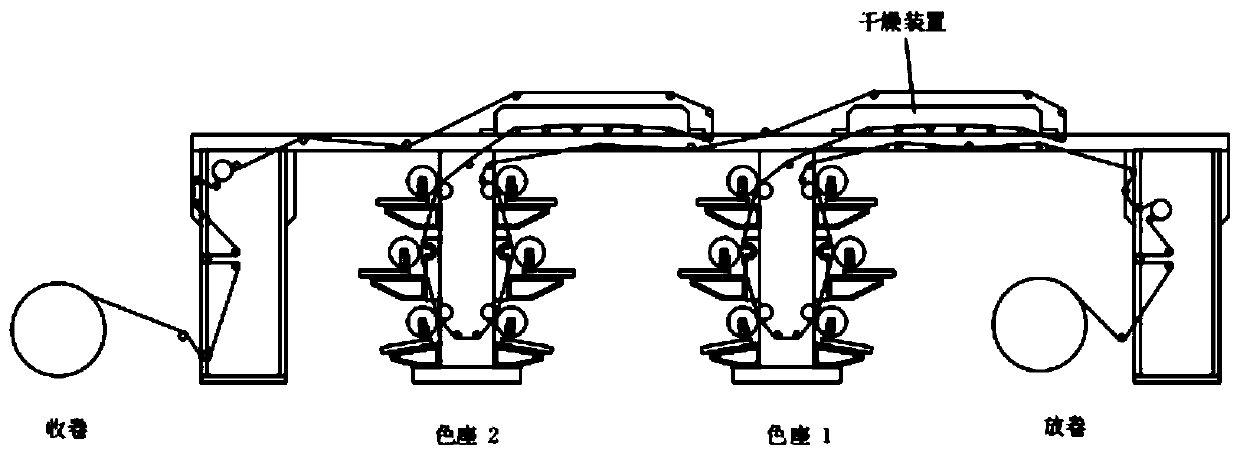

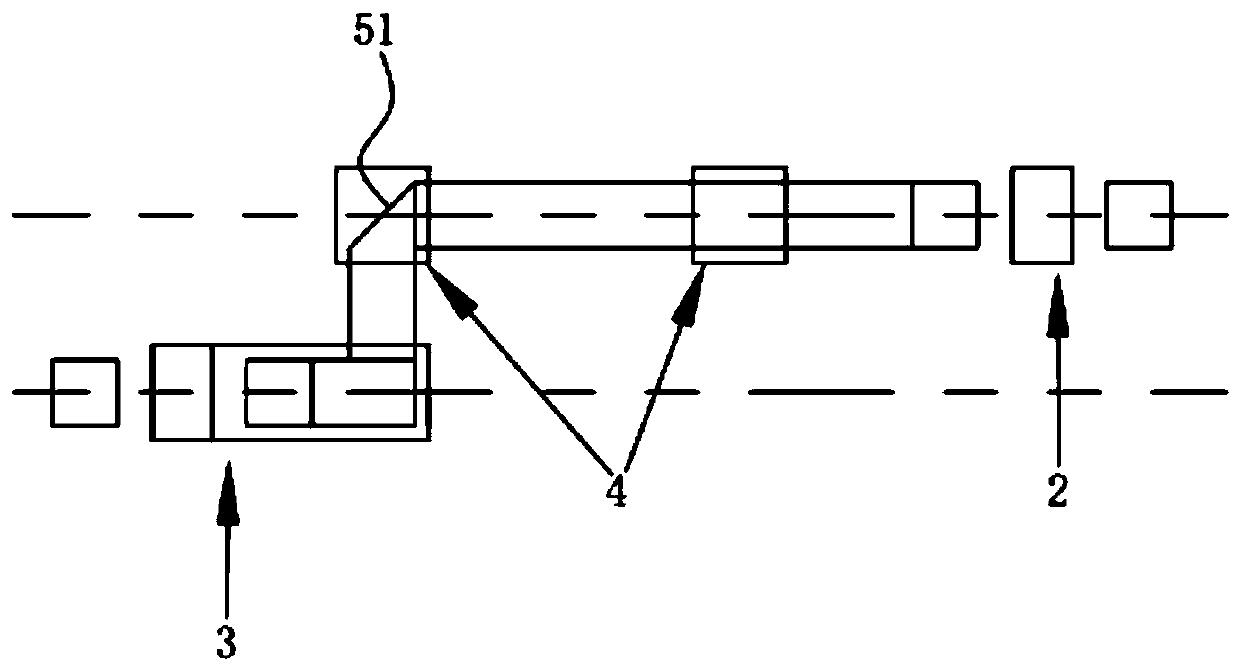

[0052] refer to figure 2 and image 3 , is a kind of printing / coating equipment disclosed by the present invention, comprising an unwinding device 2, a frame 1 and a material receiving device 3, and the frame 1 is provided with a traction device 6, at least two sets of printing / coating devices 4, rear Drying device 7 and some rollers 5;

[0053] Wherein, the unwinding device 2 and the material receiving device 3 are located outside the frame 1, and the unwinding device 2 and the material receiving device 3 are located on both sides of the two groups of printing / coating devices 4, the unwinding device 2, the traction device 6, the two A set of printing / coating device 4, a post-drying device 7, another traction device 6 and a receiving device 3 are arranged in sequence, so that the coil 8 discharged from the unwinding device 2 passes through the traction dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com