fixed length processing machine for pvc pipe

A processing machine tool and fixed-length technology, which is applied in metal processing and other directions, can solve the problems of low cutting efficiency, pollution of the environment, and low precision, and achieve the effects of convenient operation, high degree of automation, and high cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

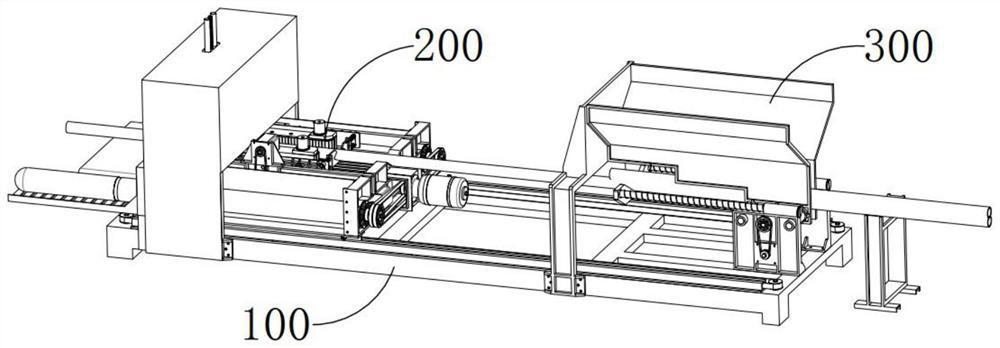

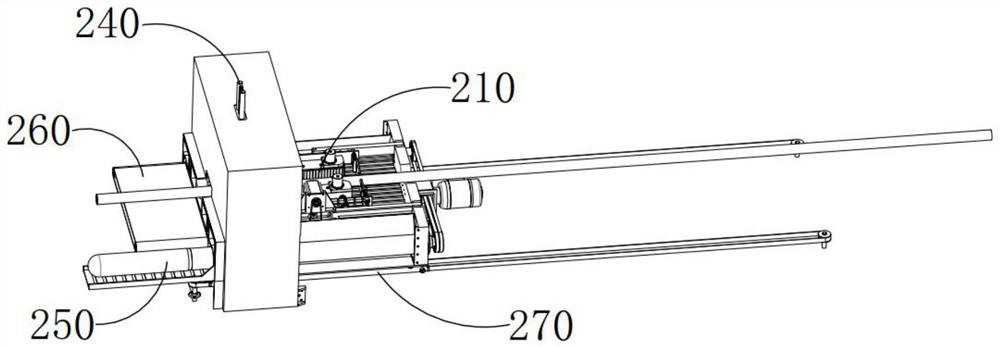

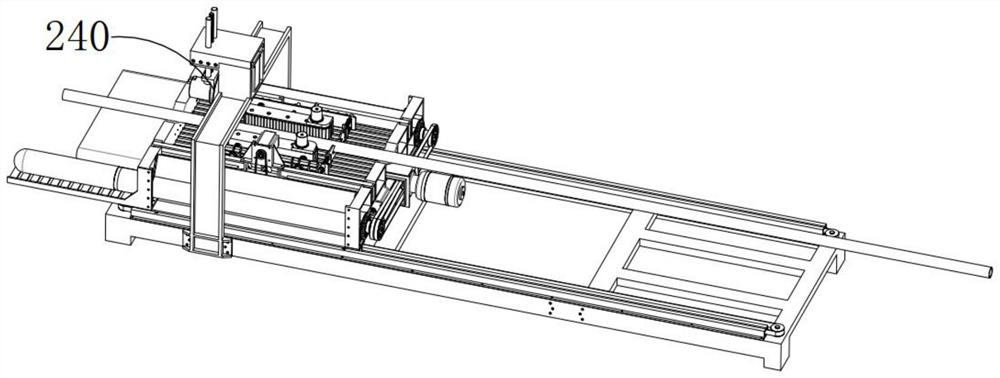

[0065] see Figure 1-34 , a fixed-length processing machine tool for PVC pipes, which includes a rectangular underframe 100, a cutting part 200, and a feeding part 300. At the other end in the length direction, the cutting unit 200 includes a clamping mechanism 210, a cutting mechanism 240, a slag discharge mechanism 250, a material discharge mechanism 260, and a sliding drive mechanism 270. The clamping mechanism 210 is used for guiding, clamping and clamping the pipe fittings , the cutting mechanism 240 cuts the clamped pipe fittings from top to bottom, the slag discharge mechanism 250 is used to collect and remove the debris that falls from the pipe fittings cut by the cutting mechanism 240, and the discharge mechanism 260 is used to cut off the pipe fittings from the cutting mechanism 240. Afterwards, the fixed-length pipe fittings that fall are discharged outside, and the sliding drive mechanism 270 can drive the clamping mechanism 210, the slag discharge mechanism 250, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com