Soil remediation system

A soil remediation, No. 1 technology, applied in the field of soil remediation systems, can solve the problems of troublesome manual processing, time-consuming and laborious soil, clogging of screening nets, etc., and achieve the effect of improving efficiency, reducing labor intensity and improving effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

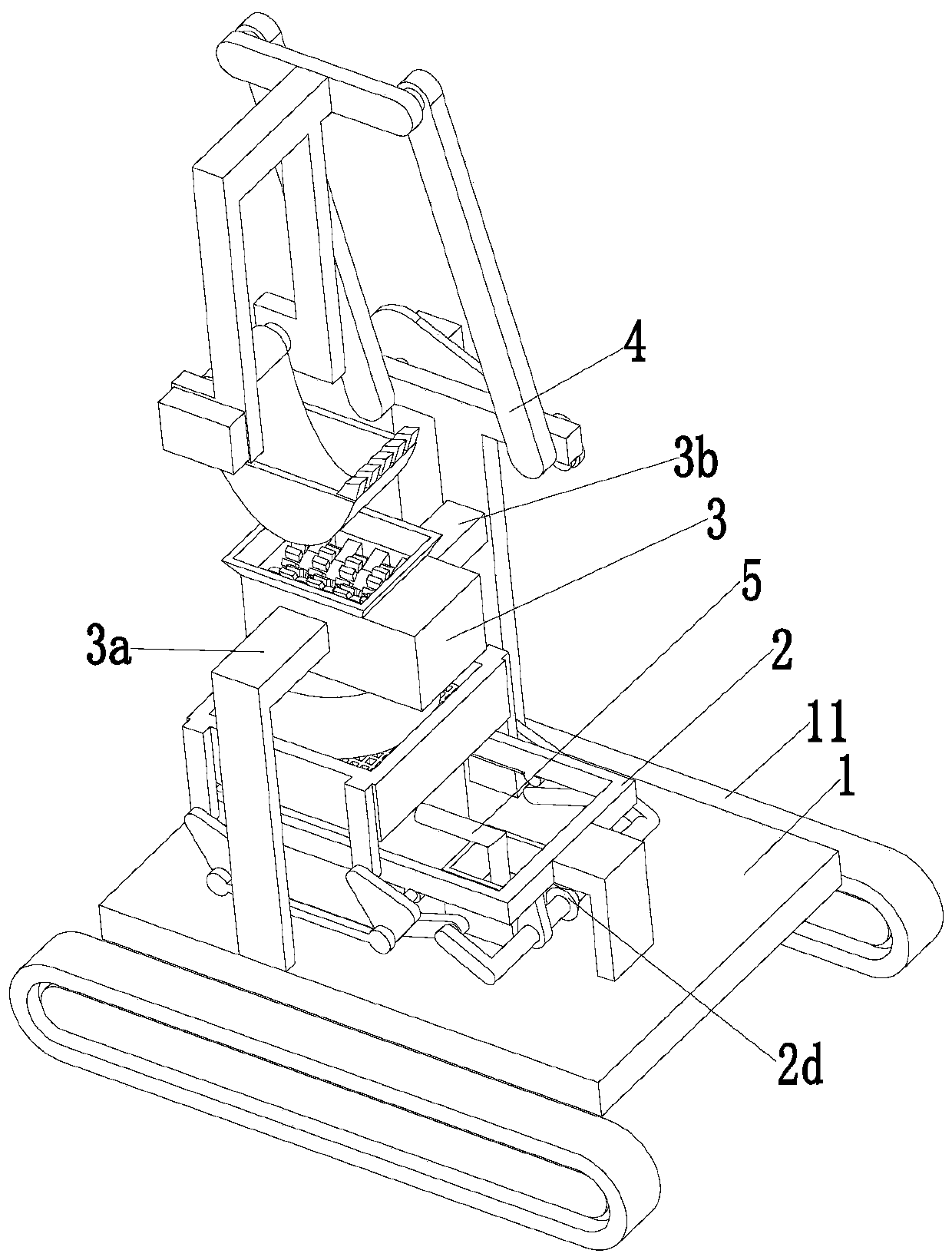

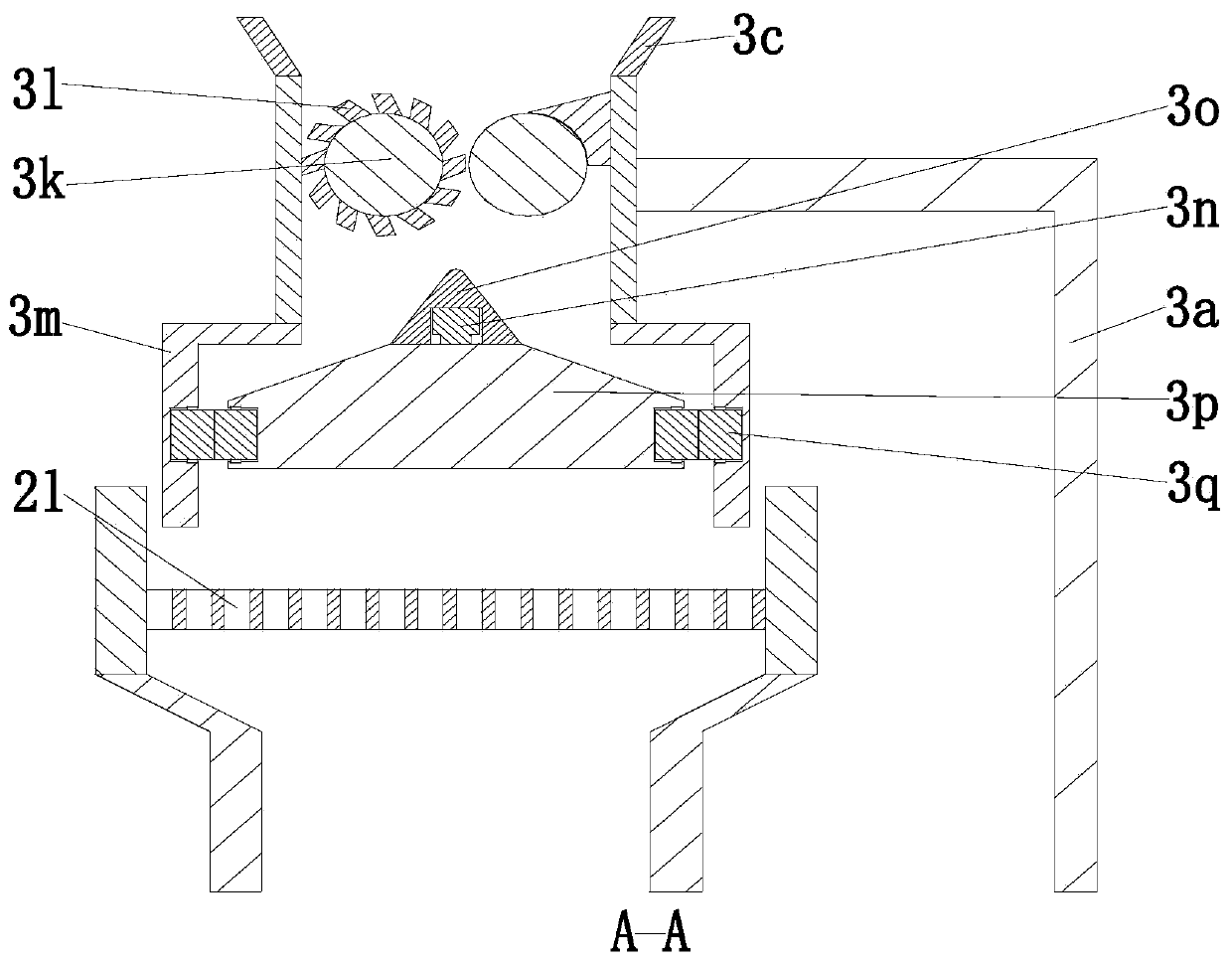

[0025] Such as Figure 1 to Figure 6 As shown, a soil repair system includes a base plate 1, a vibrating device 2, a crushing device 3, an earth digging device 4 and a recovery device 5, the rear end of the base plate 1 is equipped with an earth digging device 4, and the middle end of the base plate 1 is equipped with a Vibration device 2, crushing device 3 and recovery device 5 are installed on the bottom plate 1.

[0026] The earth digging device 4 includes a No. 2 motor 4a, a support plate 4b, a T-shaped bar 4c, a rotating shaft 4d, a power disc 4e, a Z-shaped bar 4f, a straight bar 4g, a square bar 4h, a U-shaped bar 4i, and a straight plate 4j , No. 3 motor 4k, rotating shaft 41 and claw 4m, the left side of the rear end of the base plate 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com