Non-contact line parameter measurement system and measurement method

A line parameter and measurement system technology, applied in the measurement of electrical variables, electrical measurement, capacitance measurement and other directions, can solve the problems of insecurity, reduced efficiency, unadjustable lightning protection gap, etc., to achieve simple operation, reduce on-site operators, shorten the Effect of Line State Transition Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

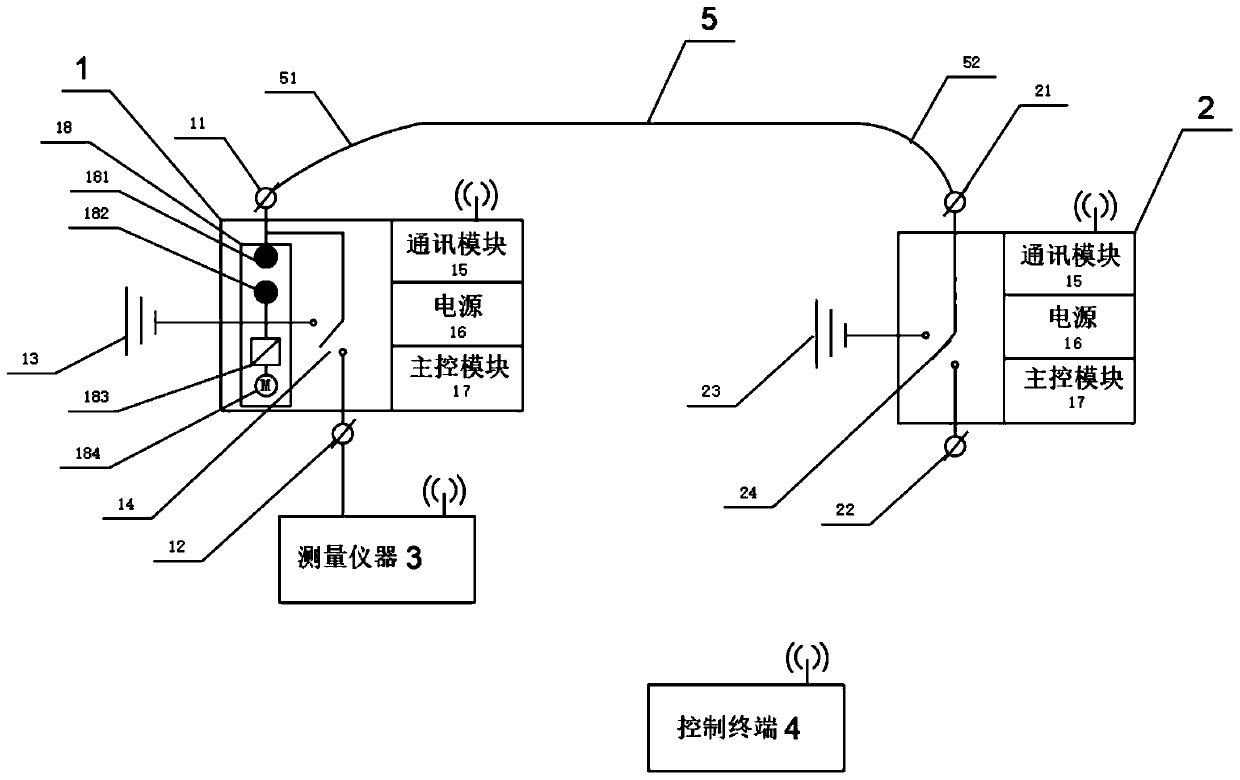

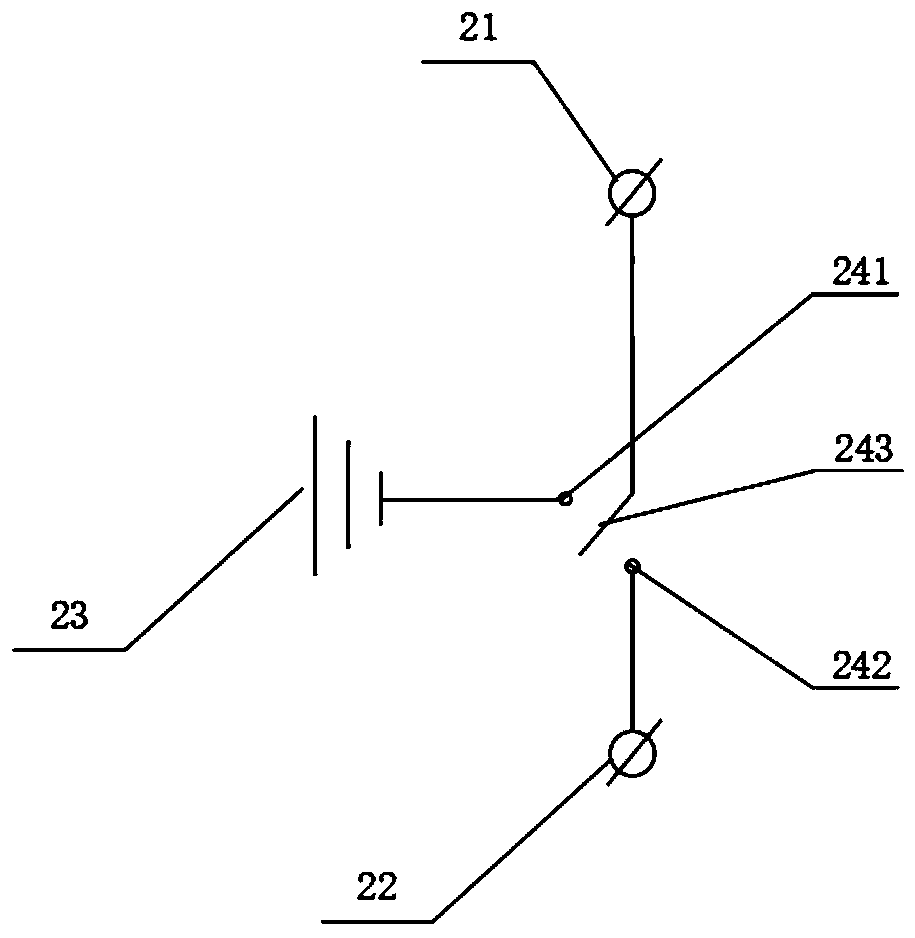

[0035] see figure 1 As shown, the present invention provides a non-contact line parameter measurement system, including a measurement terminal device 1, a state conversion terminal device 2, a measuring instrument 3 and a control terminal 4; the measurement terminal device 1 and the state conversion terminal device 2 are respectively connected to the The first down conductor 51 and the second down conductor 52 of the circuit 5 are tested.

[0036] The measuring terminal device 1 includes a first incoming line terminal 11, a first outgoing line terminal 12, a first grounding terminal 13, a first switch 14, a communication module 15, a power supply 16, a main control module 17 and a lightni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com