Non-contact mirror spacing measurement method based on matrix optics calculation

A non-contact, optical computing technology, which is applied in the direction of optical instrument testing, measuring devices, testing optical performance, etc., can solve the problems of unsatisfactory lens surface measurement, limit the practicality of interval measuring instruments, etc., achieve the realization of equipment application range, improve The effect of work efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

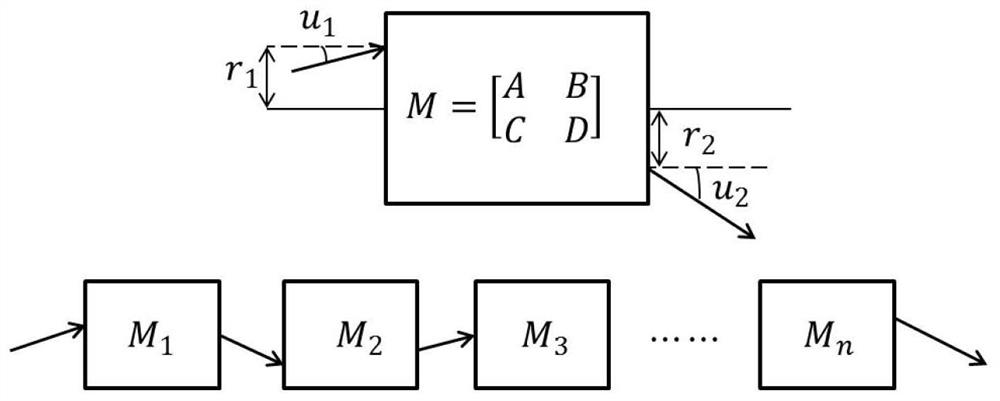

[0050] The present invention provides an optical calculation based on a matrix of non-contact method of measuring specular interval, visible light optical system for any test can be performed intelligently calculated mirror position parameters.

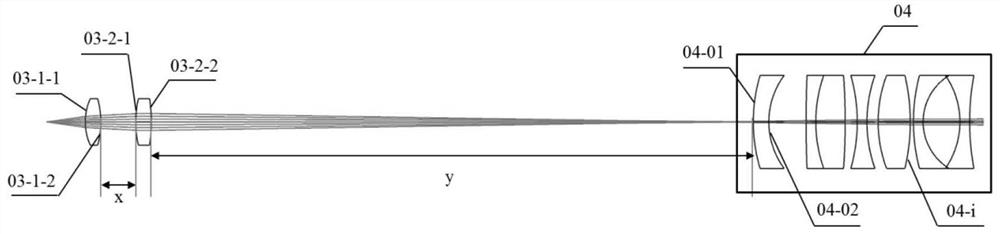

[0051] Selecting a bundle of packed standard lens, for example, contains the standard lens surface of the lens 20, based on the particular embodiment of the present invention is as follows.

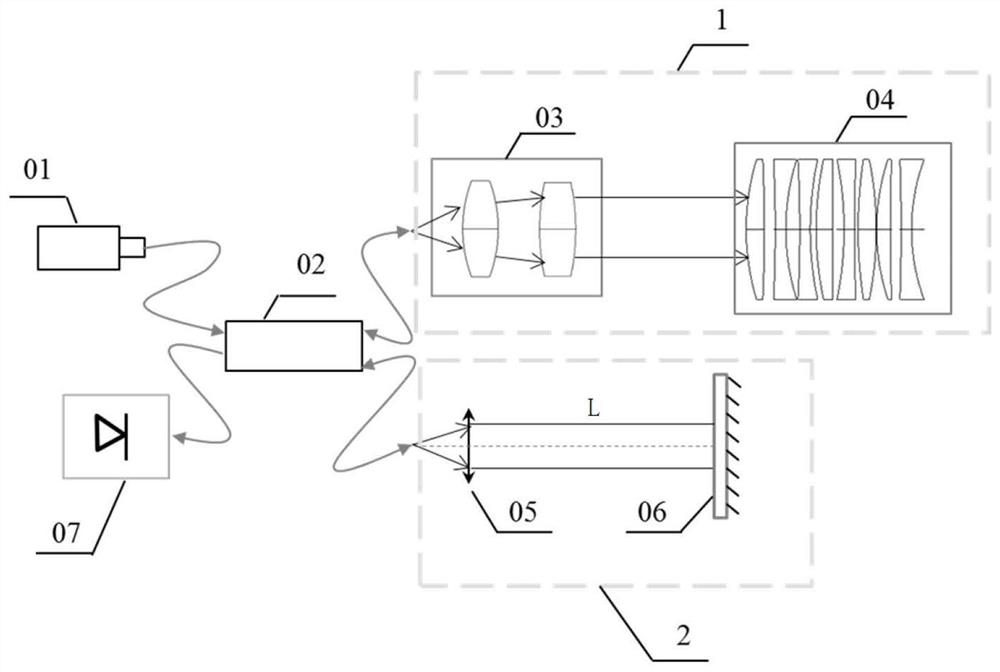

[0052] like figure 1 , The measuring principle of the non-contact distance measuring instrument specular follows: using super luminescent diode light source 01, the light emitted super luminescent diode 01 is a fiber coupler 02 into two parts, 1 all the way into the measurement arm, the light from the measuring head a collimator 03, and reflected by the surface of each lens tested lens group 04, and then return to the fiber coupler 02; all the way into the reference arm 2, comprising a delay line L, a collimator lens 05 by the light collimated by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com