Highway pavement structure utilizing waste residues

A technology for expressways and pavement structures, which can be applied to cohesive pavements, roads, and roads paved on site. It can solve the problems of high maintenance and management costs, lack of road construction materials, and high cost, and achieve energy saving, emission reduction and protection The effect of ecological environment, ensuring construction quality and technical performance, and reducing project cost

Pending Publication Date: 2020-08-04

XIAN HIGHWAY INST +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The problems faced in the construction of roads in wind-blown sand areas are: lack of road construction materials, and the construction of traditional pavement structures mostly uses materials such as lime soil and sand and gravel, which require long-distance transportation and are expensive

There is still a lack of systematic research and summary on the engineering application of aeolian sand in China. After completion, it may also face hazards such as wind erosion and sand burial, and the cost of maintenance and management is high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

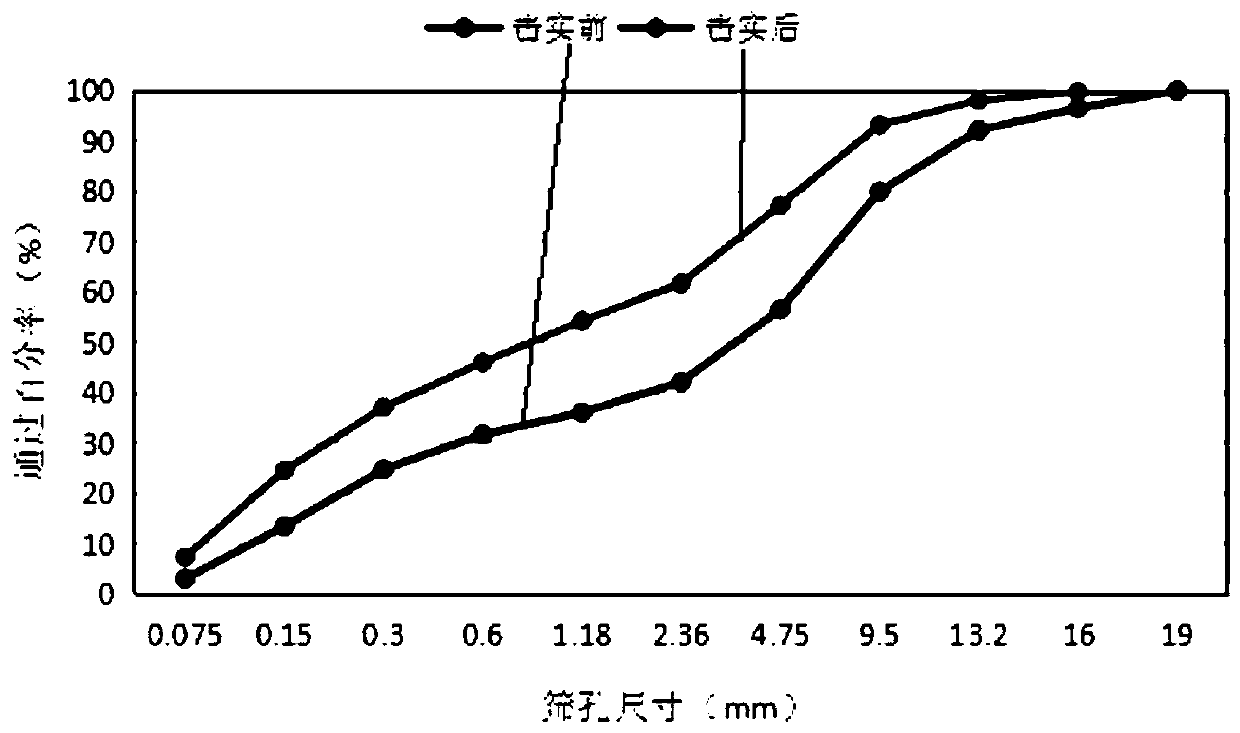

[0060] Cement waste slag stabilized aeolian sand subbase 1: including 7% cement, 20% power plant waste slag and 73% aeolian sand.

Embodiment 2

[0062] Cement waste slag stabilized aeolian sand subbase 1: including 7% cement, 30% power plant waste slag and 63% aeolian sand.

Embodiment 3

[0064] Cement waste slag stabilized aeolian sand subbase 1: including 7% cement, 40% power plant waste slag and 53% aeolian sand.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

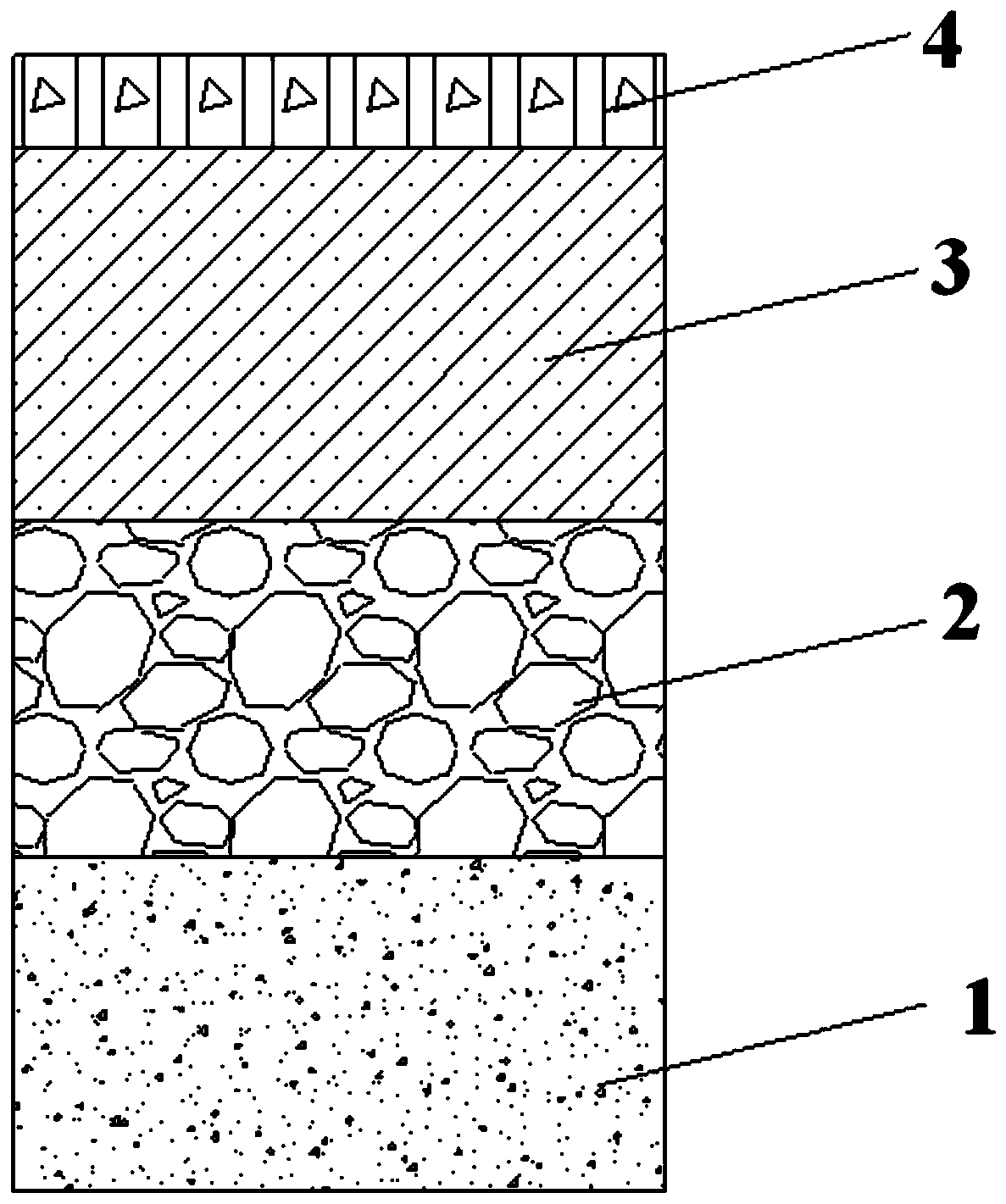

The invention belongs to the field of pavement structures, and discloses a highway pavement structure utilizing waste residues. The highway pavement structure comprises a subbase layer, a base layer,a lower surface layer and an upper surface layer which are laid from bottom to top, wherein the subbase layer is a cement waste residue stabilized aeolian sand subbase layer; the pavement is simple instructure, the prestressed concrete layer is adopted as the lower surface layer, the advantage of high strength of prestressed concrete is utilized, longitudinal and transverse pressure stress is applied to the pavement by applying oblique prestress, and the flexural-tensile strength of the concrete plate is improved; in the cement stabilized aeolian sand subbase layer, power plant waste residuesare adopted to replace part of aeolian sand so that the compressive strength of the cement stabilized aeolian sand subbase layer is improved, and the 7d unconfined compressive strength of the obtained cement waste residue stabilized aeolian sand subbase layer is 2.0-2.8 MPa; the strength of the cement waste residue stabilized macadam aeolian sand base layer can still meet the requirements of Technical Regulations for Construction of Highway Pavement Base Layers; and power plant waste residues and aeolian sand can be effectively utilized, and the production cost is low.

Description

technical field [0001] The invention relates to the field of pavement structures, in particular to a highway pavement structure utilizing waste slag. Background technique [0002] In recent years, under the action of heavy traffic, the asphalt pavement often suffers from diseases, which affects the service life of the pavement. On the other hand, with the continuous deepening of China's industrialization process, industrial solid waste is increasing year by year. As the main body of China's energy industry, coal-fired power plants produce solid waste every year, which not only puts huge pressure on the surrounding environment, but also causes waste of resources. . [0003] Solid waste from coal-fired power plants (i.e., power plant waste residue) is mainly produced in the process of coal-fired power generation. After high-temperature combustion, pulverized coal forms a pozzolanic-like mixed material, mainly including fly ash, waste residue, debris, etc. In addition, with t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E01C7/32E01C3/00

CPCE01C7/32E01C7/325E01C3/00E01C3/003

Inventor 李娜马润前贾德生徐希娟郭鹏飞张名成李晓娟周新锋

Owner XIAN HIGHWAY INST

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com