Efficient hardness removal device for high-concentration industrial waste liquid treatment and method thereof

An industrial waste liquid, high-efficiency technology, applied in mining wastewater treatment, water softening, etc., can solve the problems of high chemical cost, high equipment investment cost, affecting the efficiency of advanced treatment, etc. Construction investment and construction area, the effect of reducing the dosage of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

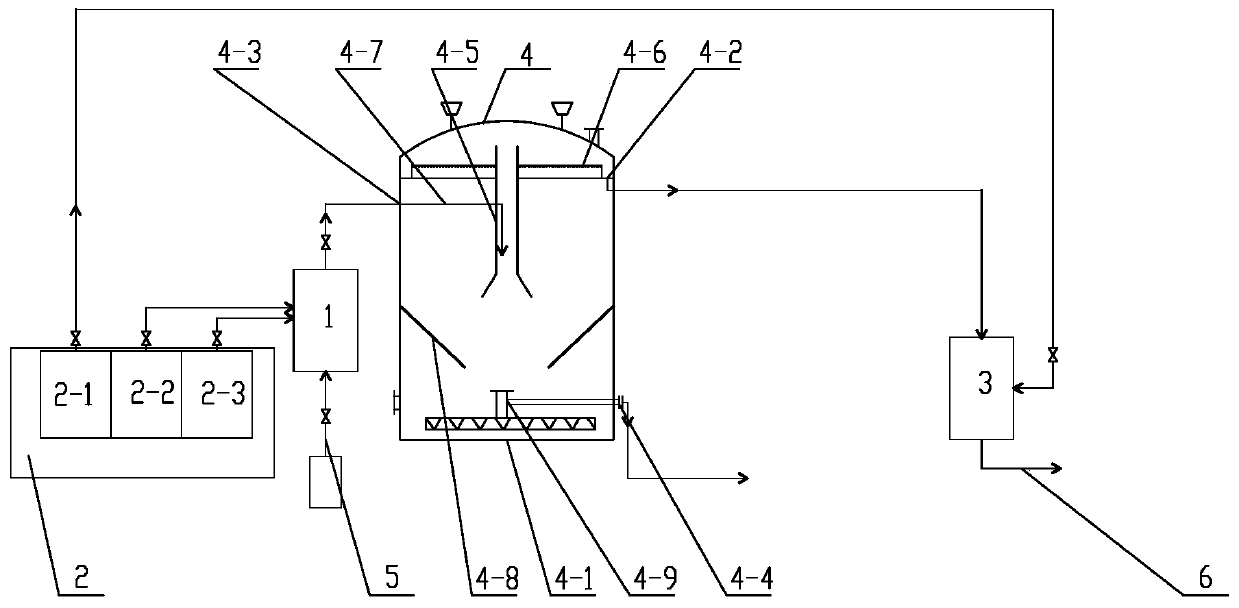

[0030] Embodiment 1: as figure 1 As shown, a high-efficiency hard removal device for high-concentration industrial waste liquid treatment includes a water inlet pipeline mixer 1, a drug dosing device 2, an outlet water pipeline mixer 3 and a first-stage settling separation tank 4; wherein, the drug dosing device 2 Including hydrochloric acid dosing tank 2-1, sodium carbonate dosing tank 2-2 and sodium hydroxide dosing tank 2-3, the outlet of sodium carbonate dosing tank 2-2 and the outlet of sodium hydroxide dosing tank 2-3 Both are connected to the dosing port of the water inlet pipeline mixer 1 through pipelines;

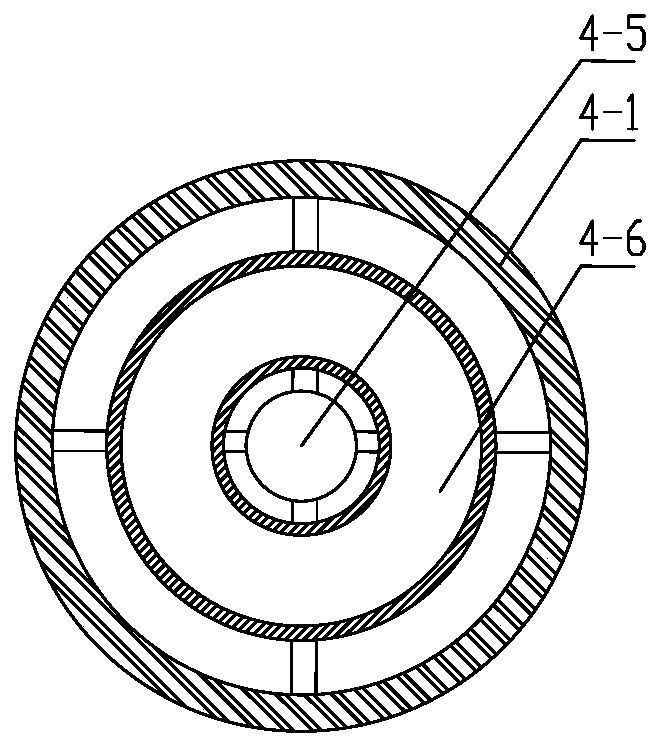

[0031]The primary settling separation tank 4 includes a primary tank body 4-1, the upper part of the primary tank body 4-1 is provided with an overflow water outlet 4-2, and the primary tank body 4-1 at the bottom of the overflow water outlet 4-2 is provided with There is a tank body water inlet 4-3, and the bottom of the first-level tank body 4-1 is provided wit...

Embodiment 2

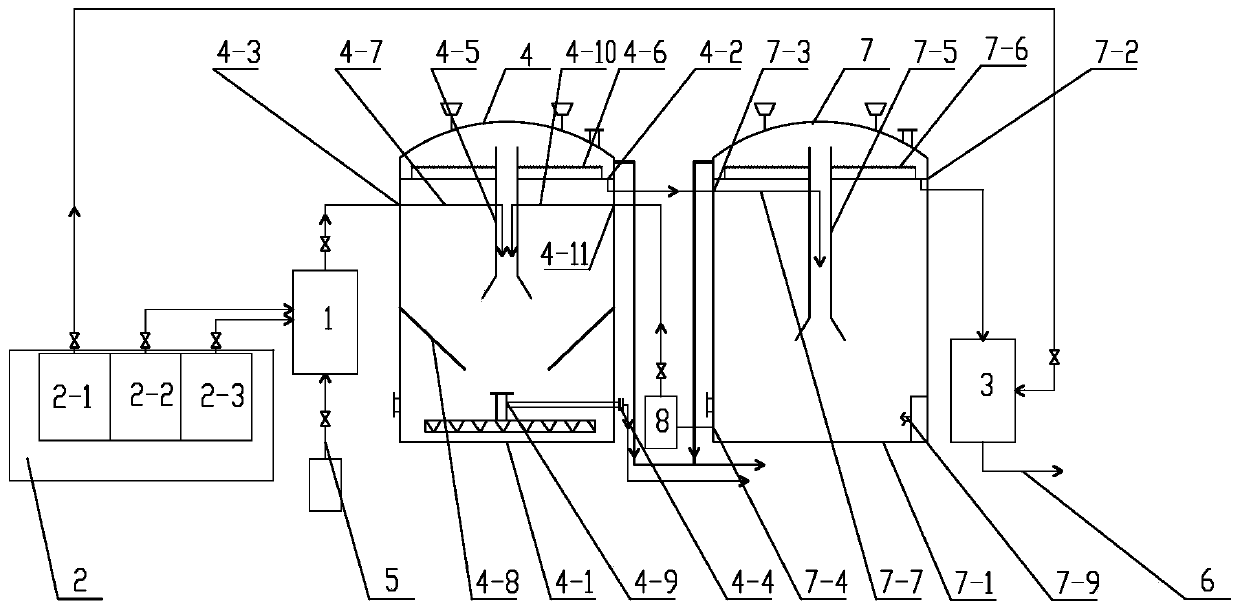

[0036] Embodiment 2: as figure 2 As shown, a high-efficiency hard removal device for high-concentration industrial waste liquid treatment is different from Embodiment 1 in that it also includes a secondary sedimentation separation tank 7, and at the same time, the primary sedimentation separation tank is also provided with a return pipe 4 -10, the top of the primary tank 4-1 is provided with a tank body return port 4-11, and the return pipe 4-10 is located under the annular overflow tank 4-6, and the water inlet of the return pipe 4-10 is connected to the tank body The water return port 4-11 is connected, and the water outlet of the water return pipe 4-10 is placed in the central tube 4-5.

[0037] The secondary settling separation tank 7 includes a secondary tank body 7-1, the upper part of the secondary tank body 7-1 is provided with a secondary overflow water outlet 7-2, and the secondary tank body 7 at the bottom of the secondary overflow water outlet 7-2 -1 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com